I used a Takagi for floor heat in my last house, and found that there was a DIP switch on the control board that allowed you to increase the max temp from 140 to (as I recall) 165. Yours might have the same if you still need to up the temps.

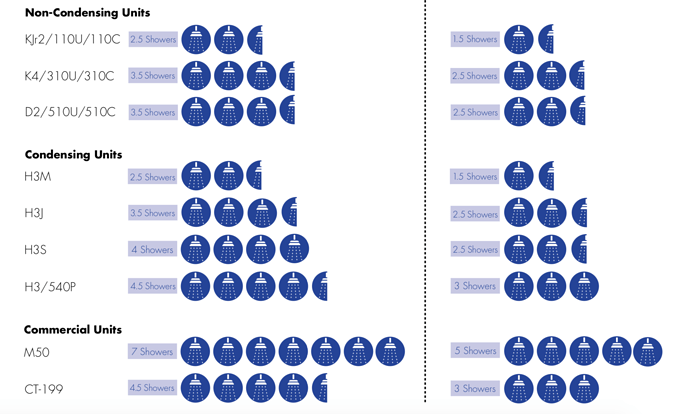

Unfortnuately, it doesnt, but thanks for the heads up and for anyone else ordering one should double check before finishing ur order. Make sure its the 540p model and make sure it goes up to 160f. There are two models, dont get the one with circulation built in, that one is limited to 140f.

I called the manufacturer and they said thay my particular (sub) model is limited to 140f.

I had the 160f earlier and it was faulty from the start.

Ive made all my money back on the FFE in less than a month. So i think im going to buy the 160f model and replace it out, maybe turn the 140f one into a DIY hot tub heater haha

IE, preheat that cold ethanol solution ![]()

that just seems like a bizarre way to set the controls on a tankless heater. if the input water doesn’t need heating, don’t heat it. just cause it’s already hot doesn’t mean the user needs less of it!

I’m not questioning that you ran into a unit that was set up that way, I’m suggesting that the engineer who built didn’t understand the problem…

I’m think the way it’s configured. I was trying to locate the best one for the price range at the time. I forgot the brand name but had to adjust the flow by a screw. I adjusted the screw to see if it had a sweet spot for the tempature rise. Still no luck. I’ve been reading up on tankless a lot the past few days.

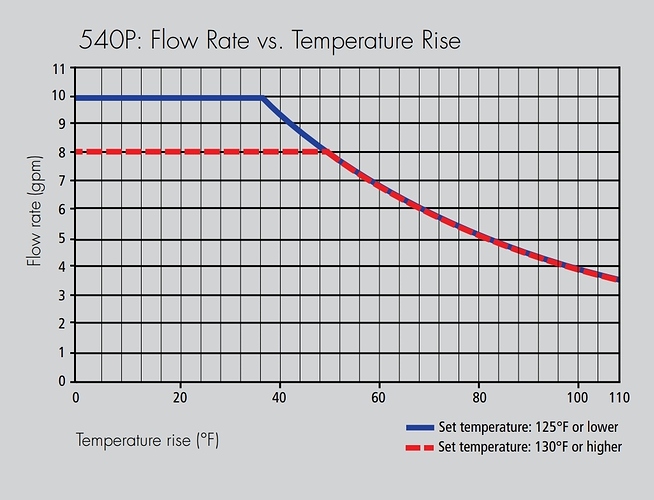

If your temperature rise is different than what is on the map, meaning there is a difference between your inlet and outlet temperature, this will affect the flow rate that can be heated. If your temperature rise is lower than what is assumed on the map you will have more flow rate capacity.

I thought of a few possibilities but here is some background info. When I initially started up I had a high flow rate than I’ll watch the flow rate drop over 5 minutes. I used an open loop. I ran a slump pump to the tankless from a 55 gallon drum. This was used for heating a closed sleeve shatter platter.

The model I had restricted flow due the temperature rise was way higher than expected. This makes sorta since bc if hot water is restricted this will mix downstream with cold water. I didnt use an expansion tank

I could have over pressurized the inlet feed due to an oversized pump.

But

@Thetetraguy I figured a solution that’s a lot easier to rig up and can redirect water flow to hot loop assist the water flow. This will keep the flow closer to the desired temperature. I’m drawing out the PID now. I’ll have it later today

@Future haha yes IE, ayee gotta have those temps as close as possible. The further it is the less efficient it runs.

Plate heat exchangers ftw

I never did get to finish my FFE, dove head first into membranes

That color remediation though

Im still kinda confused though.

My circluation pumps move it at 2.3gpm average when its fully heated. It actually circulates slower when u first start up (cold), but quickly gets up to 2.3gpm. I set the FFE to 15gph, 20gph and 25gph and it stayed flowing st 2.3gpm. While the inlet temp was dropping by about 10F each time i went up another 5gph. 15gph = 10f drop from 140 outlet. Meaning its eating 10f of heat before it returns to the heater. At 25gph it returns liquid closer to 110F but still flows at 2.3gpm

Im thinking about just rigging a circulation pump in the middle of my HE tower, thats probably where it needs the most help. Its going up alot of baffles.

I still want to see what youve got brewing up though

I do have an expansion tank, doesnt show in the bottom picture but it goes right in the middle of the wall mounted piping.

The volume inside the heated cllosed loop is alittle under 5 gallons. 1 gallon for each heat exhanger, 1/2-1 gal in expansion tank and another 1/2-1 gal in the piping

So it takes 2 minutes to fully cycle my solution. Im trying to get it under a 1 minute.

My piping and hose is all 3/4" and my HE inlet and outlet are 1/2".

Maybe a splitter/manifold that can take heat and evenly distribute liquid?

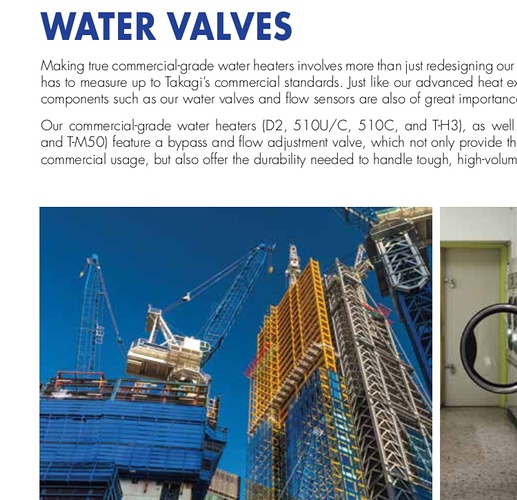

Hey, Ive had a busy day and just got done with the PID. I found the Takagi catalog. A couple of inserting things. Tankless water heaters are base upon temperature rise(Delta). They have a chart of GPM vs delta rise. The lower the delta which in our case would mean a higher flow rate. The temperature has no data passed at a certain temperature. Im guessing they have a fail-safe protocol in place. Then if this is the case a temperature sensor for inlet feed is governing a throttle valve. They have water restriction valves inside your tankless according to this catalog.

Regardless of the reason, you’re getting less flow. After researching they have two options. The first one is a basic by-pass manifold with modifications. The flow won’t go then we finna split it towards a turbo heater. The second option t will require more work but will pay off. The PEX will individually heat each part of your system. No more series flow. I’ll help you if you go this route but ill need some info. The basic recirculation could have flaws on equipment placement but i added this in the notes section.

Turbo Literature

$304

Your specs i found are

-x2 recirculating pumps at 8 GPM.

-tankless flow rate is adjustable to 10 GPM. Achieve 10 GPM requires 40 PSI inlet feed.

Im going to suggest insulating the FFE. They have polymer blends used for these temperatures. Your losing heat from ambient temperatures. Replacing inlet and outlet tubing to cooper. Im betting your immediate inlet and outlet bends from he tankless are playing with the fluid mechanics of it also.

I still dont think the valve is restricting it at all.

45f delta seems like when the valve starts restricting flow, which makes sense because i see a slower flow on startup.

I dont want to use electricity so those boosters wouldnt work. Im just using my -20c chiller as far as electricity

Insulating and throwing another circ pump or two in i think would do it.

Looks like my goal is now 8gpm according to that chart

This is a term that I seen a lot its “cold sandwhich” phenomen. It describes what your saying. They are recommending adding new cold water into the lines before tankless inlet feed. Also consider what I’ve mentioned a couple of days ago about adding a a heat exchanger for chilling water before the tankless inlet feed.

Have you checked the internal bypass line inside of it?

The last output port on the FFE would be the coldest spot in the loop. which should be your coldest spot possible move the pump there.

They have a reasoning why almost everybody is having issues with temperature and flow. I’m not sure if anybody is getting a full delivery on there factory specs. It’s not the manufacture bc they are having the desired results coming from utility water. So it has to be the way we’re looping these. I know there is extra head pressure created through the pump while water is transitioning from hot to cold.

I see the valves. what I don’t see is why they would be set up to perform in the manner you are suggesting…

restricting flow when the inlet water does not need heating makes zero sense. turning the heat off does. restricting the flow and leaving the heat ON would lead to overheating.

restricting flow when the available heat input is not enough to achieve the users requested temp gain also makes sense. and is a good match for the graphs shown. ie MAX flow is achievable when required delta T is lower. (this also matches @Thetetraguy’s experience).

having a bypass valve which activates when the inlet water already meets users requirements another reasonable response.

I’m not restricting flow. I’m adding more flow to the system. The item is a custom manifold bypass. This will Heat the water traveling through it. It’s open bore if I’m not mistaken. If the pump is rated for 8 gpm. The valves are stop check valves making sure water doesn’t back flow. The tankless sensor is redirecting cold water to supplement the gpm output. I’m betting the psi gauge is higher on that end than inlet.

The path of flow won’t go into the tankless it will collide at the Tee connector. The expansion tank is a chance to equalize water temps

sorry. I wasn’t meaning to imply that your additions were restricting flow.

you have however described a tankless water heater performing this trick (restricting flow on high inlet temp) on you in an unwelcome manner (which is as I understand it the rational for your additions).

I am restating my confusion as to why a tankless water heater would come from the manufacturer configured thusly.

having looked at the literature you posted. I’m not convinced that they are engineered as you suggest. certainly I can see no logical reason for setting them up that way.

other than a dead stop when upper exit temp is exceeded on inlet.

They weren’t meant for this type of application but we have been modifying them to make it work. Yes they have recirculating hot water loops but they all have cold water being introduced.

Tankless were meant for utility waters. This includes water temp and psi of the water being fed to homes.

I’m unaware of any inlet temps at 120 degrees coming from any company or well. They suggest certain models due to geographic locations. Tankless is rated on rise temperature (delta) and Tube feet.

I will be more than glad to share all the info I have. I found most have an internal bypass line with a throttling valve.

How many taco pumps have been burned out to quickly? This is due to them working harder bc of pressure. I think of this as a a normal straw and making it fit inside a mixed drink straw. Thats force feeding and creating back pressure which makes the whole line more pressurized and the pump is trying to feed more water into it.

both of which make sense…

bypass when inlet is hot.

throttle when inlet is cold. (to increase delta T, at expense of flow)

throttle on hot inlet, not so much. (will increase delta T).

valve mentioned in 1k word substitute is to match flow with desired delta T. bypass is to deal with hot inlet (don’t need to heat it…)

Can you give a logical reason for throttling flow on hot inlet? I can’t. which is why I’m dubious. engineers do redundant. they seldom do superfluous or non-sensical (deliberately).

@Thetetraguy’s symptoms are certainly not caused by flow restriction on hot inlet.

the burned out pumps I have run into had all been run dry.

I agree we’re using them off label, and as such I’m willing to concede that there might be a sound reason for implementing a control system that throttles on hot inlet. If you figure out what that is, I’d love to understand.

We arent using them off label. They are meant for this specific application. They usually are used to heat flooring with pex manifolds, with circulating glycol/water mix. When desired temp is reached inlet and outlet (140f) the propane/power on the heater is restricted, infact it turns it self off when it reaches 140f for more than 3 minutes and turns itself back on when it reached a delta 3f or higher. While its turned off it doesnt restrict flow.

Sorry but im with @cyclopath i cant figure out why it would work like that, and ive sat there watching the thing operate and i dont think it works the way u think it does

My uncle has a well that pushes out 140F 24/7, we live next to a geyser and hot springs. I wish i could set up a huge FFE there, it would litterly run for free. Other side of the property has a cold well. Back in the 50’s he had all his houses with copper lines installed underneath that uses the hot water, also had FAT greenhoused all heated and watered off that hot water. Irrelevant, but i still wanted to share because it thought it was very cool he had, what most of us think of as modern now.

hot and cold running hot & cold? and NOT growing and processing there? we ought should have a chat with your uncle. where does he live?

I agree that using domestic water heaters for hydronic heating is very common, but it’s not how the OEM @Juice311 pointed to seems to be positioning them…even the commercial ones.

I got bored trying to find a heating unit that seemed purpose build for hydronic heating that wasn’t a DIY project. Saw lots of companies willing to install a hydronic system using either tanked or tankless domestic water heaters.

Ill give u a hint he lives next to one of the three old faithfuls ![]()

so not in the land of the wrong white crowd…

After reviewing this I misread some things and thought too hard into it.

-Series run the pumps after the tankless outlet port. This will increase head pressure.

-Series run the booster heat exchanger before inlet water on the tankless. less delta in your HE which will increase your flow rates.

-Have the expansion tank before the first heat exchanger(booster). this will help with fluctuating temps from the processing system.