I mean yeah but who trusts Chinese customer support?

Bvv. Lol.

bvv = you get slightly more customer support than a direct from china source

I’ve been pretty happy with BVV as of late… Bought some gas and a BVV cmep rebuild thing on 4/20. Pump does a really nice job. I recover at 108, and pull down like .8+lb/min and their canister have been clean AF no booboo gas yet. ![]()

Who wants to collaborate on glg pumps ![]()

Iv seen pdxgold pumps in action quiet and crazy recovery speeds. 16grand tho

Hmmm, this is probably similar to the Punisher from Precision in that it’s a clone of the Corken/Blackmer style reciprocating gas compressor with a crosshead design.

Similar to Precision, I’m guessing BVV has theirs manufactured in India.

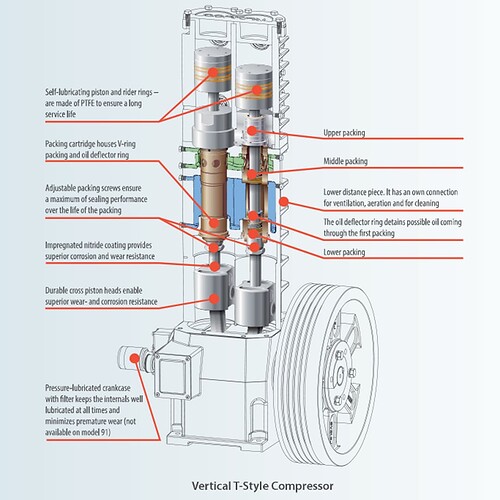

See how the diagram below from the Corken T-style compressors have the lower, oiled pistons and con rods like a normal engine but then it has the piston rod attached to the top of the pistons which go through seals (packings) then up to the oil-free pistons? This is what “crosshead” design means. I think most of the huge marine diesel engines are designed like this.

One thing to keep in mind with these types of compressors is that the lower pistons/rods are oiled and the upper pistons/rods are oil-free. You can see the Corken T-style (T=triple) has three different sets of packings and an oil deflector ring. This is used when you need maximum assurance that the upper chamber is oil-free like we need in our case for cleanliness, or if you’re pumping something super dangerous like ammonia.

Judging by the height of both the Precision Punisher and this new offering from BVV I would guess they are both only a single packing design, but I’m not sure about that. I wouldn’t want to take any risks so I would want double packings and an oil deflector ring at minimum, preferable triple packing/oil ring like the Corken T-series.

Second major point I notice about the BVV pump is the fact that it’s a two-stage design. Don’t confuse that with two-stroke, it’s not that same thing at all.

The two-stage compressor design basically feeds the output from the first cylinder into the intake of the second. This allows a higher pressure ratio across the compressor (outlet pressure:inlet pressure)

According to Corken’s literature, single stage compressors are best suited to applications where the gas compression ratio is 5:1 or less. Generally this compression ratio is fine for the vast majority of BHO extraction systems out there. There will be times where you’re over the ratio for a little bit but my T291 has been handling it just fine for several years now (propane) and it’s what was recommended to me by Corken after explaining my run parameters.

Not sure why the discharge pressure is so low on this BVV pump. It claims to be using the dual stage design to allow higher outlet pressures and ability to pull a vac (there’s no need to ever pull vac with the recovery pump) but the max outlet pressure is listed at 150PSI. The single stage Corken’s are good to go up to 350PSI right out of the box.

Even the T-91 corken with its multiple packing’s will allow oil to make it past the rings into the process side if you pull a vacuum with it or recover columns with it into negative pressures.

Corken explicitly told me to not run it below atmosphere.

Yes that’s correct.

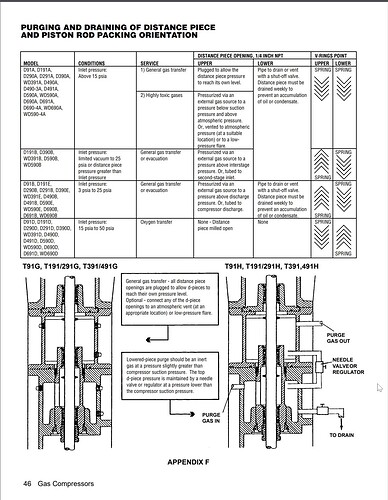

I believe they’re mostly talking about oil climbing the distance pieces under heavy, consistent use in the vacuum range without the proper packing orientation. There are multiple different packing/spring arrangements that can be used depending on the expected conditions, some work for vacuum range.

If you touch the vacuum range while finishing recovery using a compressor with the normal gas transfer packing arrangement (inlet pressure only above atmospheric pressure) you should be fine.

For our situation it makes the most sense and offers the best protection to set the packings to seal under positive pressure only and just never pull a deep vacuum.

I have never found it necessary to pull deeply into the vacuum range with the recovery pump. When I’m doing final recovery I stop the compressor at 0psig and let pressure rebuild if I need to recover more solvent.

If you look at the righthand column on the page below it shows the different packing/spring combos.