I have a 6 inch chinese wipefilm that I’ve been troubleshooting for 2 weeks. I’m at my wits end with.

It was working fine until randomly mid run things were no longer condensing. Full disclosure. I did accidently leave the warmer heat on and circulating over night. But IMO that shouldnt be a contributing factor. Just like an extra long shift.

The main evaporator body’s jacket is too hot to touch everywhere but a 90 degree slice directly on front on the bottom adjacent to the fluid input port.

I’ve tested the warmers temperature, its accurate.

Ive swapped the warmer with one of the same model. Temperature accurate. Front bottom of jacket still cold.

I’ve borrowed a buddies huber warmer. Better. But still not hot in the same spot.

I’ve taken the warmer off my other wiper that was running just last night. Verified to work. And put it on my “broken” system. Same problem. WHAT THE FUCK.

I’ve tested the voltage coming out of various outlets. Its good. All outlets are on their own breakers.

I thought maybe my hoses were clogged. Cleaned em out. No change. Put on new ones. No change.

I’m using duratherm s and rarely go over 182c. Never over 200c.

The only thing I can think is maybe my fluid viscosity has changed, can that happen with duratherm under normal parameters? Or my glass has spontaneously rearranged to fuck up the fluid circulation.

I’m pretty competent when it comes to repairing these units but this has got me stumped. Maybe some tannerite would help…

Please someone give me some ideas or solutions!

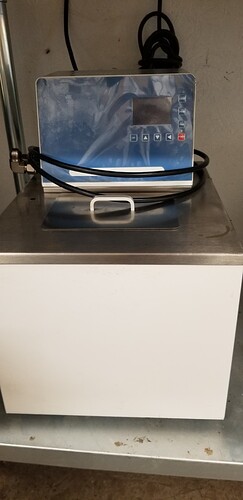

20220514_150054|690x335

The warmer from our other facility which worked great last night there does not work here. Power is good. Hoses are swapped. The only remaining variable is the fluid. I’ll probably drag these two “broken warmers” to our thc facility and hook em up and verify the functionality.

But god damn. How can 3 chinese warmers and 1 huber all have the same problem. When 2 weeks ago none of them. Again, the power supplies have been tested and verified to work

Are you using a high quality, mfr rated heat transfer fluid?

@Sidco_Cat were using duratherm s. I believe its -55c to 300c

Not sure if its mfr rated but duratherm has never been a problem in our open bath warmers so far. Infact it’s been preferable.

1 Like

Can you change the flow rate on the heaters?

Could it possibly be an imperfection in the glass constricting flow to the corner of that jacket?

3 Likes

I can change the flow on the huber cc508 but on the Chinese ones… no. I pulled a motor and googled it. Looks like 1250rpms. The huber is 1500-4500. At 3750 the huber works okay but I dont want to overclock it or run at max.

Heres the thing though, nothing has changed in the glass and it’s been working fine since I bought this column. So maybe 6 months. Machine itself has been running for 4 years. Plenty of problems along the way but none I havent solved.

And just when I thought I was a master chinese wipefilm troubleshooter fixer upper.

1 Like

By “warmer” I assume you mean “heated circulator”. Because “warmer” brings heat tape to mind first…you’ve got some of that showing.

If the “better” circulator (Huber) was better, but still not right, and you are using the (exact) same fluid in both (all three) the simplest explanation would be a change in flow.

That could be a blockage, or a change in viscosity, and I guess the physicists can’t rule out “change in glass”, my guess would be a restriction.

What I did not hear was flow rate comparison (timed return to bucket, without draining your circulator) from your two stills. Use the same circulator. Or better both on both stills.

The “pumps” in those circulators are robust, but not super powerful. Have you looked at the pump head(s)?

Circulator flows…but does it flow at the same rate on both? No? Why? Clean and repeat.

Same flow rate on both stills?

Black Magic.

Apply tannerite at will.

2 Likes

Check the flow rate with and without the coil in line and compare the two. You either have insufficient flow, some restriction or an air bubble.

If only one spot is not getting hot your recirculators are probably working and there is something else going on.

Try switching the flow direction from the inlet and the outlet and see if the cold spot goes away or moves.

3 Likes

Ive been using the same 15 gallons of duratherm s for well over 5-6 yrs. Decarb and hot condenser, between 155c for roto decarb and 165-180c for hot condenser, no noticeable degradation and still functions like the day i opened it

1 Like

Hehe. Yes. Warmer - Heat circulator.

Good ideas. I’m driving to our other facility to hook these bitches back up. I’ll clock em!

Warmer 3 on wipe film B works. Warmer 3 does not work on Wipe film A.

Warmer #2 worked on wipefilm a 2 weeks ago. I thought it broke so Replaced pump motor. No fix. Havent clocked rpms but motor turns freely very easily. Still no fix.

Warmer #1 broke lcd screen broke and has been used for scrap parts.

Huber warmer works on wipefilm A. but still have to run at 190c to heat all of the column despite great vacuum

I’m going to take warmers 1 and 2 that are broken"warmers and hook up to wipefilm b that is verified to work with warmer 3.

I’m baffled as to why warmer 3 works on wipe film b but not on wipefilm a. I’ve swapped hoses. Verified no restrictions. Verified voltage. All is good except for the cold spot.

It’s so cold I’d be comfortable rubbing my nuts on it. All three.

Update.

I’ve hooked our recently “broken” warmer #3 to wipe film B. IT WORKS.

Having verified the lines are free of obstructions, power is the same at both facilities and on both wipers. The only variable I’m left with is the fluid…

What happened to my Duratherm S at our hemp facility I’ll never know, but the duratherm at our thc facility has a very obvious difference in viscosity and flow.

I think I have my solution after 2 weeks, replacing pumps, motors, entire recirculators, driving to washington to borrow a buddies huber (thanks @KandThegingchemist).

Who would’ve thought my fancy fluid degraded. Glad I Frankensteined the shit out of my good warmer.

Also big shout out to Sam @BioXtra for always returning my calls and sourcing me replacement parts for my wiper.

5 gallons Duratherm S ordered and on the way.

3 Likes

Curious about your roto decarb… are you saying you just use it in open bath roto?

I hate how we cant decarb our shit through our little roto at our thc spot. For production flow weve resorted to decarbing on 1st pass wiper which is annoying.

If you’re using the fluid in the bath, what do you do about all the greasy shit all over the orb?

Yeah i just reprogrammed an across and swapped the fluid for duratherm s. After its done decarbing i let it go to 150-155c and let it strip some volatile’s and then just raise the ball let it drip dry for a few and then take a paper towel and wrap around the joint just in case any drops drip down. I do wipe it off with a towel real quick so its not covered and use a pair of ove gloves from the infomercial, it pours out fast cause its so hot. If your using a 20l a 12 gallon garbage can from walmart will hold it upright perfectly and over time will form to the ball. Never done it with a 50l i would use a pump for that but been doing 20l and under for 7-8 urs now. Ive never decarbed in the still or in a pot. Use to go straight from roto to wiper no cool down and set it and forget it. Chinese ones ( not that across isnt) don’t need to be reprogrammed from my experience

3 Likes

Thanks for your message.

We’re right there with you, providing everything for all your extraction needs and full support as always.

1 Like

Hi Bro,

Have you eliminated the malfunction of the wipefilm main evaporator ?

We are professional manufacture of molecular distillation in China, if you need help, I can ask our engineers for you. : )