@pangea is right.

Get a gauge built for this (digivac) and check.

Try some flushing oil as well. Blank it off, let it warm up, drop the vac oil in it, add the flushing oil, let it run for 30-60 minutes, empty that out, then put fresh oil in to see if that helps as well.

4 Likes

duhhhh… cause its sucking, my bad I had it the other way around in my head, ok very good thanks for the tip I will do this, cheers Pangea !

4 Likes

60 microns ain’t bad neither… The real test is going to come when you try to pull down your entire system with it dry. If you can pull it down to below 100 that would be pretty decent. Then you’ve got the cold traps when your running that will help you pull down further. You gotta test the pump on the system, you need a better gauge, but you’re doing better than you think you are!

Thanks bro, that’s very encouraging, I will definelty do that tomorrow

1 Like

Blanked off with that setup you should be able to hit 10 micron or less. If the fittings are all good, I’d suggest changing oil again. Especially if that was the only change between your 3 torr and 60 micron (suggests volatiles got into the pump). If that doesn’t help, you may want to get the gauge calibrated (it looks pretty new, if it’s from the factory it shouldn’t be off by that much). I would not distill of you can’t get below 10 micron blanked off, you can assume about 1 decade above blank off for your running pressure and you want to stay below 100 micron

3 Likes

Sweep some helium over the fittings. This should show if theres a bac leak present. I’ve posted a few pics of the vac pump and fittings I use.

I drained the oil and like you said, it was pretty dirty, filled it up and ran the pump for bout an hour then I drained the oil again, it came out pretty decent so I stored it and filled it up again with fresh oil, pump is running pretty smooth.

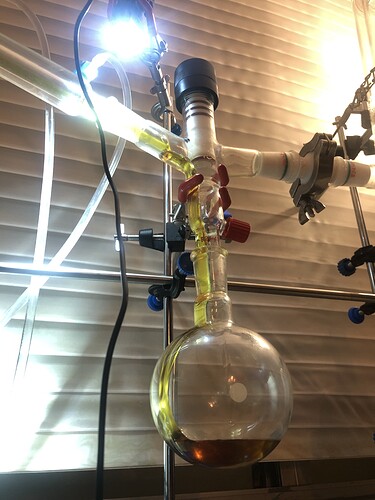

I connected all the glassware and the max vac im able to pull at the moment is 310 microns, im pretty sure the gauge I got is working because it reacts to very subtle adjustments.

Im gonna get some helium tomorrow like @Demontrich suggested to check for leaks, I already applied the Apiezon vac grease to all possible fittings, I really don’t know what else I could do to stop leaks once I find them with the helium, any tips would be great.

Also I would like to know if I could do a run with 310 microns or what’s the least minimum I need to achieve to start my first run ?

Cheers

2 Likes

Ok so im able to get down to 45 microns now with all the glassware and thermometers in place, im using teflon tape on the KF25 PTFE fittings, is this ok ??

I think im gonna have to start my first run at this vac level because its been 3 days now and I have not been able to get any lower than 45 microns.

I wanna do a practice run, anybody have good tips on what material I should use ? I got a gallon of virgin oil from Costco I have been thinking about fractioning the MCTs from it but don’t have any idea how to lol, any tips are very welcome.

1 Like

@Capttripppp @GroovyOctopusLabs @Demontrich @SidViscous @HeisenbergInd @spdking @pangea @The_Lone_Stiller

I Fucking did it boys !!!

I just wanted to thank you all for all the help you’ve given to me, it would of been impossible for me to achieve this without yawls help, im uber grateful and really fucking high on disty at the moment. Wish you all great Karma!

11 Likes