Well, a little more than 30 days ago I received everything I asked for via ebay in the United States here to Mexico, I have to tell you who difficult to introduce all these components through customs and here in Mexico it is practically impossible to buy them at a good price. The whole team arrived and I think I am ready for my first run, I have enough information from this forum, thank you very much for sharing so much information about cannabis, in Mexico this legalization is coming and many of us are interested in learning.

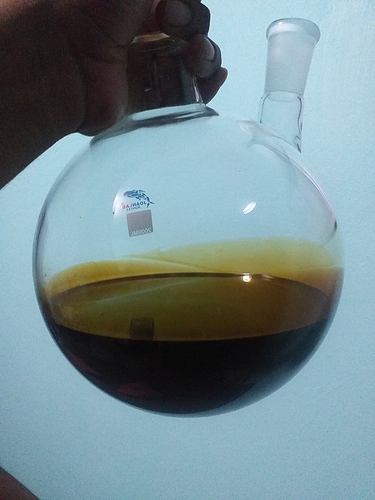

I have some questions. I’m about to start my first run, I already have the oil here (photo) I understand that by this time, my oil must have been filtered and the ethanol evaporated. Now I have a viscous liquid inside. I need your help to start with this process. The crude in the distillation flask was extracted from low quality plants, I do not know the concentration of cannabinoids, it was brought to winterized 48 hours at -8 ° C and filtered with activated carbon in grain and decarboxylated. Now I would like to know if you could say if my equipment and its configuration are correct or I may have a problem in the future of this round. I read there several posts about pressure that have left me confused. Annex photos of the equipment to use. Greetings and thanks for reading.

You can also filter over aluminia, celite 545 or t-5. If you can go down on the temperaturw for the winterization, you’ll get better results. Post here your equipment for distillation, vacuum pump is also take an important role on the distillation process. Must to be atleast below 1000 microns.

glad to see that youve goten setup! i remember you posting a few months ago you’ve come a long way since then, bravo!

winterizing at -8c for 48 hour might be sufficient, but not ideal, did you pull some lipids? it may be worthwhile to winterize again, colder if possible, dry ice and a cooler works decently in a pinch.

it never hurts to filter through multiple medias, it will improve final product quality and coloration.

post some pics of your distillation set up, and we can tell you if everything is set up right.

as far as vacuum depth (you mention pressures is this what you mean?), the lower the vacuum you can pull, the better. what pump are you running and are you running a meter? be sure to have lots of pump oil on hand to ensure the longevity of your pump.

Also heres a few tricks,

-run your pump for 30 min - hour blanked off before you start your distillation, if your pump oil is at the ideal operational temperature(hot) before you start running, you’ll pull a better vacuum quicker.

-i always start the run with the gas ballast open, and close the gas ballast when i hit the gold and swap the fractions.

-Also you can pump down the system quicker with the gas ballast open, wait untill the depth stabilizes, and then close the gas ballast to acheive your pump/setups ultimate depth. youll achieve your ultimate depth quick this way, then just pumping down with the ballast closed.

-heres something i always tell people, Dont be afraid to switch flasks mid run to learn the different fractions. Practice this process a bunch, so you can do the flask changes smoothly, quickly, and efficiently. Isolation adapters are ideal for this, look into getting one for your setup if you dont already have one. Also practice greasing joints, alot of people get this wrong when they are just getting started, seems like greasing a joint is a no brainer, but there is a little bit of a technique to get optimal seals!

best of luck,