Active but I’m about todo the passive upgrade

Close off your cold collection during recovery. Wait a minute for any residual vapors to condense then burp. Open it back up and repeat. Depending on your system i can just leave my recovery tank air vent open for a few minutes and my pump will push everything out. This is one reason why running straight butane is nice.

It works the same way w passive, dumping nitro outta the cold recovery tank if ur not cooling ur collection or recover at the same time…the nitrogen will move over to the cold recovery tank then vent it off there a couple times by shutting the valve off to recover let psi drop some then vent the recovery…after venting open it right back up…the recovery will help pull down gas u have left behind

Well Update.

Got my hands on some nice material. pulled a 12% return on 2 runs with same crc stack. i used the above list of ingredients minus the alumina. both runs came out really white and first run wasn’t very terpy more dry. If i cut the crc in half will that give me more terps and more blond look. or should i run throught the same crc for 3rd run. trying get nice light yellow

Yes less media means less remediation and different media steal more terps

But also yes, the more runs you so they the same stack it obviously gets darker, so mixing the fist second and third runs will probably give you the color you want

Think im going try 400grams b80, 120grams silica gel. this time. i got 3 runs left i can do with materil left. 5lb a run

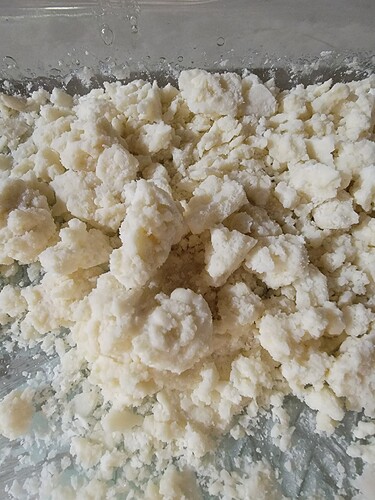

Top first run then 2nd run. These are results from using . An un measured cup de at bottom. 800grams b80. 227 grams silica gel. Ran through same column both runs. 5lb material.

ah damn i didn’t see this comment lmao

think i should run it just 400grams of b80? no silica gel

Definitely you can do without the DE

And maybe without the silica if it’s not leafy stuff…and if you don’t want the white stuff…

B80 does awesome yellows

What he said !!!

^^^A lot of the answers to the OP’s questions are in this comment.

I absolutely agree that 2 mic is important.

Some points you may not have considered:

If you are having trouble pushing through using granulated media and 50/60 PSI, the slowing is almost surely not due to packing the media too tight. I’d be looking to clogging/slowing in your filters/papers/etc. I’d also be considering if I was getting a vapor lock in the column. I can do runs through 1 micron sinters never going above 35psi. This wasn’t always the case. The solution was in resolving vapor locks and a specific cleaning/staging procedure for all filter components to prevent slowing.

The “pull” from your pump/recovery is as important to getting gas over as the push.

CRY/CRX are very practicable products, IME. 250 gr/pound has the ability to remediate very poor quality material to bleached white. That much media seems extremely high to me based on my experiences with the product. I doubt insufficient media is the route of your lack of remediation. To whatever extend you can slow flow through your media, you’ll maximize it’s remediating capability.

The very high amount of media hurts your yield to some extent. Since you’re currently running dry ice, consider that you’re running much colder than you normally do and that’s hurting yields. Don’t skimp on the gas ratio. You need to give it enough gas to get the product. If your flow is slowed, you’ll have to extend flow times to get the same.

Definitely past this point just trying dial in my crc I had 12% return last run . It was bad material I was using

Also I have 1micron sintered disk in my crc stack for all concerned.

.2 micron is what you want if you’re running media

Glad you decided to drop the granular media.

*i think this a good time to remind you that there is a difference between ADSORPTION and ABSORPTION.

That being said, you’re definitely on the right track although you may need to make a few adjustments.

First things first, you need to filter down past 1 micron if you’re working with B80 and Silica. 1 micron might work for granular media pretty well but trust me when i tell you getting B80 in your collection vessel is not fun and having to get creative with ways to re filter your oil is stressful and time consuming.

Get yourself a Sintered Media Filtering Disc and filter down to .2 micron to catch everything. this disk fits in a gasket and you can put it underneath your 1 micron in your filter stack.

Studying these powders is fascinating, as you can see people above me have explained the uses and more about some of them. There are a lot types of media out there and they all do different things and can help achieve different desired outcomes so i definitely encourage you to research them in general because what are you even trying to make in the first place?

You can drop the celite.

Activated Alumina isn’t mandatory but i personally think it can serve good purpose. one of the better parts about working with it is the more coarse size of the grains opposed to very fine clay like b80.

T-5 and B80 are both bentonite clays and where you’re going to actually see most of the color remediation but you don’t need both…

Silica is great as well with the only adverse effect being it absorbsTHC which means lower yields. obviously we don’t want this so finding the best ratio is definitely important.

More important than any of these great media selections we have to choose from is how you apply them to your process. You’d be surprised what you can do with small amounts of B80 and Silica alone and it sounds like you’re starting to see this for yourself but you’re still using a lot for 5#. Remember the more media you use the more solvent you’ll lose.

If you pack your column correctly and run it properly you can probably cut down to like 400g of B80 and 75-100g of silica and still get great results. it may not be completely white when you recover it but it’ll taste better for sure and it won’t be as dry.

Remember that you can mix medias too. I mix a little bit of B80 and silica in my stack.

Packing your column properly and your flow rate/ exposure time are probably the two most important things when it comes to getting the most out of your remediation set up. i’ve had runs come back dark on the first time and colorless on the second simply because of difference in the flow rate between runs despite using the same media.

How much solvent did you use, and did you soak your material column when you pulled that 12% run?

That’s .22um

True, Arborfab has them listed as .2 micron on their site though.

Edit: didn’t catch the .02