I have a choice between two double coil condensers for a 5 liter rotary evaporator.

One splits into two coils at the top and then recombines at the bottom.

I am told this is more efficient, because the coolant circulates in one direction and exits, as opposed to the other coil design, where both ports are on the bottom, and the coolant has to circulate from the bottom, to the top and then back down.

I would think the system which feeds the cold into the top, where the vacuum is pulled from, might be more efficient, but I’m also unsure if one port that splits off into two coils, will guarantee an equally distributed coolant flow. And if it doesn’t, then maybe the option with both ports on the bottom is best?

Any insight is very much appreciated. Thank you!

As far as efficiency it really doesn’t matter. Any work done to elevate the fluid is given back when it falls down. The fluid should fill the coils bottom up, because as it fills any air is excluded and purged out of the system automatically.

Pretty much the bee’s knees. You can hook it up to a 1.5hp chiller and a 4 head pump no problem and cruise.

That sure is a lot of hype…our rotovap is half the price and guaranteed faster so you should probably remove any marketing claiming yours as the “fastest” rotovap ![]()

@spdking Yeah I was just looking at that monster from summit! I was trying to see which way the coils were set up in it… the input and output are on top and bottom… But it has a triple coil so I figure it could be one line running up, down and then back up again? They have a 5 liter model but there was no info on it yet. That looks like a mean machine!

I only have a cheap Chinese unit, I’m still brand new to this.

As for the dilemma between the two different coil configurations, the reason I had to ask, was because I ordered one from a company and in the picture it had all the ports on the bottom. When it arrived, I saw the port on top and thought it was a 2 liter so I sent it back.

They want to send me the same one again, and claim it’s a better setup than the one I wanted, but their prices have went up (from China supply issues) and the model with all ports on the bottom is still available but is now a different name with an even higher price than their new version of the one they want to send me. It has me confused and unsure if I’m getting played out.

@goldleaf_scientific thanks for the tip, like I said I’m brand new… And you must have one hell of a system to out do that Maxrotovap! Much much respect to both of y’all!!

Yea there’s alot of bs going around. The key is quality and technology and offering features to the customer to extend every dollar spent to performance. I’m sorry China suppliers wasting your time.

Clown leaf who feels intimidated by my products sure has alot of shit to talk, mean I would too if my rotos came from the bottom barrel China suppliers…trying to offload 2k rotos and doubling thier money just isn’t the game or business model summit research plays.

All bs to the side. You can watch videos of basic demos on the YouTube. I have posted it with basic and not aggressive setups. So every day customer can see what they would get. With obvious upgrades to vacuum and other components you can even boost speeds. Please feel free to watch the video and make up your mind. We aren’t like these China suppliers, in a year we will still be around to handle any warranty or supper you need. ![]() our rotos come standard with a feature that allows you to empty the basin without breaking vacuum or stopping recovery. Ask us how. All you need is a hose and keg and we’ll help you out!!!

our rotos come standard with a feature that allows you to empty the basin without breaking vacuum or stopping recovery. Ask us how. All you need is a hose and keg and we’ll help you out!!!

Lmao

Membrane filtration will replace all evaporation

2 weeks till I test my dewaxing and solvent separation skids

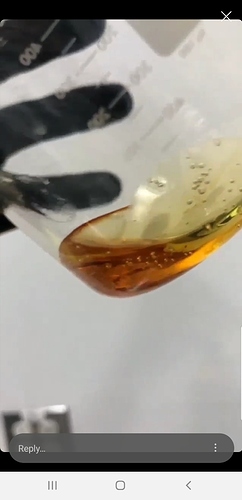

Heres a preview of the what a membrane can do

This is warm methanol extract ran through a winterization membrane (membranes use way less power then any evaporator btw)

This is after

Great job!!!

Whats the startup cost on one of those? One of my buddies works at a membrane lab that does everything lol beer, wine, milk, cannabis tincture, its definitly the future not just in cannabis but other industries. They can get beer down to a syrup like soda machines and mix it on demand. Reduces shipping costs and increases its shelf life

@spdking I didn’t realize at first that your are summit! What a trip. Is that you in the video about “the clear” with the cigar? That was a pretty bad ass video, much respect. I saw that a long time ago and thought, “I’m trying to get there”… I’m still trying to get my first little flask spinning:rofl:![]() I know you can’t fight progress, but I hope that beautiful machine you have doesn’t become obsolete too soon! If I wasn’t trying to fly on such a super low budget, I’d have reached out to you a couple years ago. I’ll definitely check your new video out tho! Who knows, if something happens this season that justifies some type of decent budget, I’d definitely reach out.

I know you can’t fight progress, but I hope that beautiful machine you have doesn’t become obsolete too soon! If I wasn’t trying to fly on such a super low budget, I’d have reached out to you a couple years ago. I’ll definitely check your new video out tho! Who knows, if something happens this season that justifies some type of decent budget, I’d definitely reach out.

Also, I was just looking at the diagram on your website today, it shows the cooling line goes in to the condenser at the top and back out from the bottom… would you say that’s the optimal way to run the cooling fluid? I know it’s opposite the advice I received above, but I’m interested what you think too…

And in your opinion, the two different coil configurations I mentioned… would you favor either one over the other? I appreciate your insight!

Optimally your heating will be ur limiting factor and in that case as long as u get the air bubbles out and have decent flow itt doesnt really matter.

You could even have two giant ass tanks outside ur lab that u pump liquid to and from u wont really waste water and the night time temps should cool it back down after a days use. Just need a decent recirculation pump

I’m working with someone from the wine industry who’s been doing this 30 years, he was telling me about some tech they use to filter out high quality terpenes from wine and how theyll add them to lower quality wines to up the price on them

Depends how big of a skid you’re looking for

Tbh were gonna be more expensive then Ethos because were going to use housing that are actually meant for organic solvents where they’re using water filtration housings that the manufacturer doesnt recommend for solvents

Safety first, especially at 600-800 psi