Anyone have some insights on how to minimize decarb during etoh solvent recovery of CBGa crude? I’m starting with 12:1 GBGa:CBG flower, but for the life of me can’t get the ethanol purged without decarbing to a ratio of 5:1 CBGa:CBG

Thanks!

following

how deep of vacuum are you getting at?

Is there a sweet spot on the vacuum

Deepest vac you can get so you can keep temps low is what I think he’s getting at.

Best luck I’ve had with CBGa was edit: 20C in the rotovap until mostly recovered, then pouring into a pan and letting it evap in a hood.

of course there is! you just need to dial in on parameters.

Increase vac pressure, lower the temperature. Ethanol will recover at a lower temperature and not decarb your CBGa.

Is nitrogen blanket essential? I’ve been pulling deepest vac with my agilent scroll pump and even let it run at 26C and still saw significant decarb

Whats your average residency time during this step

What is the % of decarb you are seeing with this method, wondering what my target should be from my initial input

I want to guess but honestly need to look up the data, it’s been like 2 yrs since I played with CBG flower.

Much appreciated thank you

if you’re at your deepest vac, the only variable you have left is to lower the temp even more.

thing is, this will make the process take longer; decarbing is a function of heat + time, so even with lowering the temp, the extended time might end up decarbing it less, but might also end up decarbing it about the same.

you may find yourself at the limit of how much decarbing you can prevent given you’re using a rotovap. a FFE would be ideal for recovering solvent while minimizing time spent on heat, but i’m guessing you don’t have that option

I actually do have the delta seperations ffe, but am still having troubles with decarb to 5:1. My assumption was to run at the absolute minimum temps possible, obviously full vac

Running around or less than 20 gph on the alicat

Mokon is set to 135F

Column temp stabalizingaround 132F

My other option is to increase flow rate dramatically and temperature slightly, but I really hate just shooting around in the dark because it takes such a large volume to get a batch test on the system

I was considering using a rotovap instead if I could minimize the decarb more effectively.

If you have ideas how to make the FFE work I obviously would prefer that

i would say the rotovap would be the inferior option, consider that as you add your solution to the flask, it’s constantly under heat, and eventually, you have your whole batch sitting under heat for a long time. more time on heat = more decarb.

with an FFE, solution sits at room temp, until it enters the machine, spends little time on heat to recover solvent, then leaves the evap area to return to room temp quickly. less time spent on heat = less decarb.

thing is it depends on if your FFE is batch-harvest vs. continous harvest. If it’s continous harvest, it’ll go much like i described above; if it’s batch harvest, it’s possible that even though your crude has left the evap area it remains in the machine under heat, until it is harvested. if that’s the case, maybe harvest more often to get the crude away from heat?

idk about increasing flow rate a lot and heat only a little. seems like that’ll just get you worse separation and more ethanol remaining in your crude.

i know the feeling of ‘shooting around in the dark’ but i think that’s solved by laying your variables out and picking different combinations of them to test. i also understand the frustration with slow turnaround time and ability to experiment and iterate, due to large batch sizes necessary. only advice i have on that is to approach it as methodically as possible, pick which variables you’re trying to test, and keep a log of notes to work back into your experiments.

also it helps if you use Celsius vs. Fahrenheit, just the common language used here

I havent tried with CBGA, so I don’t know offhand if its a faster or lower decarb temp than CBDA and THCA - but I used to rotovap (with full 29 inHg vac) at 40-42C and decarb was not considerable at those temperatures. If your vac is anything but “full” (say 27-29 inHg), you should get a better pump. You could dump your rotovap flask contents more frequently (like every 2 gallons solution charged, dump the contents) just to minimize how long product stays hot. Inert gas sweeping isn’t going to influence anything in terms of decarb.

If you have the FFE, use that first and then do a solvent switch in your rotovap to an aprotic solvent.

130F? That’s not horrible, but still quite warm.

Try 25-30C

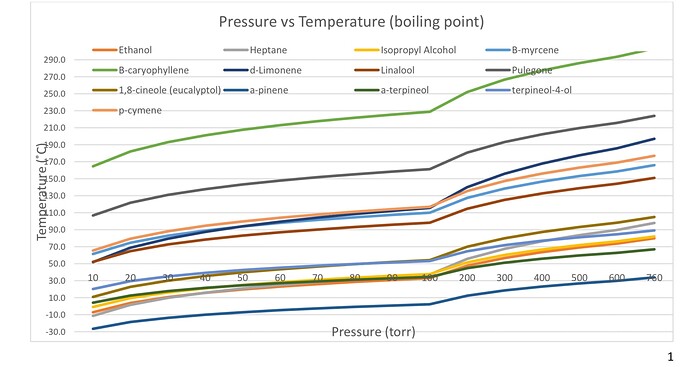

You can boil ethanol at 0C or lower if you have enough vacuum pump. I’ll see if I can locate the nonograph

I posted around here somewhere…

You could certainly manage smaller batches in your Rotovap.

Edit: not it, but looks useful enough to post…

Stolen from :https://www.nwsci.com/customer/docs/SKUDocs/RMR/Boiling%20Points%20and%20Vapor%20Pressure%20Background.pdf

It seems to want to decarb no matter what, you can almost look at CBGa sideways and it’ll turn to CBG. It also likes to solidify/crystallize during EtOH recovery IME.

thanks cyclopath

didnt know that - ya might need to avoid ethanol entirely and replace with aprotic solvent.