I’m getting consistent, above 90%, results in my extracts (winterised crude without CRC) but still there are things I’d like to get rid off. Mainly chlorophyl and red/brown pigments.

I’ve tried various metals and metal oxides with a moderate success. Looks like the hevier the metal the better removal. Right now I’m usng zinc powder and it works quite good but I’m thinking going heavier like… lead.

I’m going to use lead acetate but I’m affraid some lead could get in to final product. Anyone tried anything simillar?

Adding heavy metals instead of just using bentonite?

1 Like

Gross! just use something from @Waxplug1 new media line

4 Likes

Most clays have transition metal complexes in them already. Aluminum oxide is readily available. I’m sure they will do the job just as well.

2 Likes

AA will help reds. Bentonite with blues and green.

I’m processing hemp, usually the biomass is few months old. And I’m based in EU where most media used for color remedition (edible oils and such) are acid activated and I already noticed that the chance of isomerization is quite high. I use bentonite that was heat activated, aluminium oxide and DE as a thin cake used during winteristation.

I’m not a fan of CRC as I feel too much good stuff is getting removed and CRC’d crude event though looks better doesn’t work that well as before color improvement.

Also I’m doing alcohol extraction and CRC doesn’t work the same as with hydrocarbons.

So your final product is crude?

1 Like

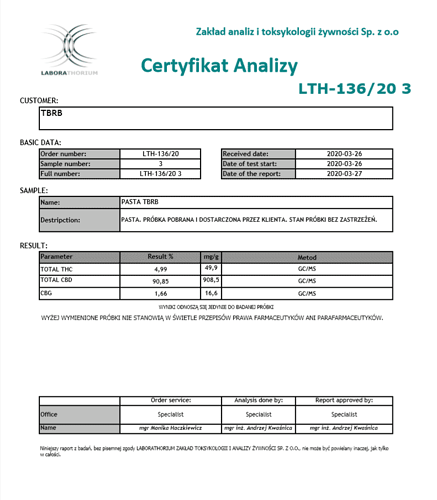

Judging by the numbers it’s getting closer and closer to a distillate even without distillation. But yeah, without getting in to semantics my final product is slightly refined crude.

That’s why I’m thinking about using metals to create pigment complexes so I could filter them out during winterisation or maybe even while I’m doing first filtration straight after extraction.

You could try filtering through crc media with molten crude oil at or above 80 c. You will want to do this in a stainless steel column so you can add nitrogen back pressure. Alternatively you could try doing this in a centrifuge.

Are you going to dissolve your product in a carrier oil? You could use the carrier oil as your non polar solvent and then adjust the ph after filtration.

1 Like

I don’t go above 75C at any point, even during decarboxylation. Some of the crude will end up in hemp oil, spirytus (95% ethanol) or other carrier but ideally all the fucking around should happen on the first filtration or during winterisation. As I’m working with 2% cbd biomass the sheer amount of solvent volume to evaporate makes going back and forwards between solvents impossible time wise.

But yeah, ss column with a back pressure sounds great. I was also thinking about a plate filter thingy used in edible oil filtration. For about $400 I can get one with 16 plates. But the plates are single use and around $10 each…

This looks interesting as well:

1 Like