That’s pretty interesting really!

Now that my new lab is set up and i finally have a rotovap, I’m going to be uploading lots of completed oil pics from different membranes in this thread. Here is a pic of an r&d run from today. Left is feed, right is permeate. Medium: heptane.

LEFT

Recent batch on a completely new brand of membrane came out even better. Same feed as the last pic, just a different membrane.

Do you have potency information to go along with these samples? That would very useful alongside color comparisons.

I’ll have some results by Wednesday most likely. I know the feed is ~55% CBD

Any updates on the membranes? How they holding up? Question to anyone using membranes…

Love em.

what exactly are you doing with them?

Fats begone?

Solvent recovery?

Which solvents?

We’ve found good success with using them for clarifying/heavier molecular weight gunk removal (20nm presently, 1nm on deck), fats begone, and solvent recovery.

Mostly with heptane and methanol, but also with water, and when I get some time I think there might be a good butane/propane application in there somewhere.

I know there are also colour remediation membranes out there, but that’s not something I’ve played with.

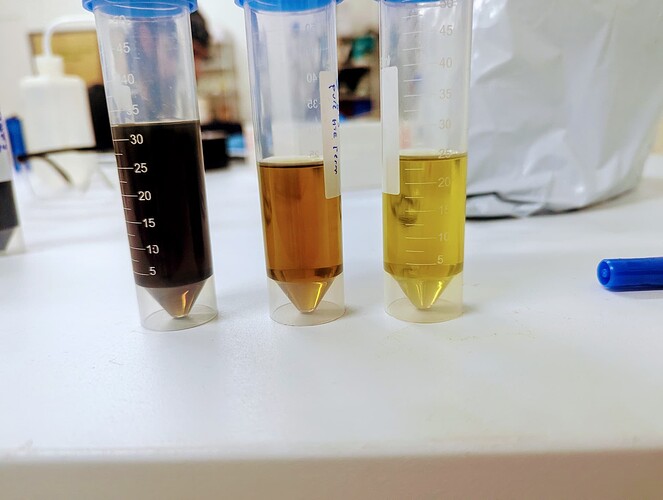

Here’s a pretty impressive picture, and a fun project. If your oil is thin enough (I.E., high terpene extract) you can put it through a membrane with no solvent at all. This is probably the best result I have got for membrane purified oil. These samples are pure oil, not solvent solutions.

Left is feed (garbage quality HTE). Middle is a looser membrane. Right is a tighter membrane. Note it was either treated with the loose or tight membrane. It didn’t use both in series.

Anyone with a few 100 gallons of dark HTE they need prettified?

maybe…

How does the smell and taste change? In your experience are most of the dark compounds responsible for the harsher smell and taste? Very intriguing work!

If a batch is run to completion, the retentate (not shown in that picture) is almost odorless. Yet the permeate does seem to have an enhanced, “fruitier” odor in the examples I tried. So it does seem like the dark junk covers up bright, good odors to some extent, though not actively bad smelling.

Is there a way to scale down a membrane system? I couldn’t imagine generating enough terps to fill the holdup volume on my Xspiral. How did you get that result in the first place because that’s really cool. Did you happen to taste the retentate fraction? I have a weird hunch.

Yeah, I did in on flat sheets. There’s a reason I said “if you’ve got a few 100 gallons”, because then doing it on the rolled modules would be great.

Makes sense. For nano production, I use 0.22 um membrane filters to remove horn particulate and bacteria, circle with 3" diameter can filter between 1-4 L of solution. It’s quite feasible even at scales of a few L. No clue how this translates as the membrane gets tighter and with the viscosity of terp fractions but what you got may be good enough. ![]()

Yeah, you could do that few liter sort of scale, it would just be a “leave it running overnight” kind of thing.

Thought so. Unsure of the feasibility of capilary/cartridge style membranes, but that would be the next step up surface areas wise.

The problem is there isn’t really a wide selection of solvent-tolerant membranes in those pore sizes and dead-end style. In fact even my flat sheet was done using a special crossflow flat sheet holder. Though this result was somewhat replicated by a friend using dead-end. So it is possible.

Have you tried crashing hte after membrane or had most thca been removed prior?