Has anyone tried to identify and quantify ALL of the compounds in a full spectrum sample? How far did you get?

90% of my butane/propane stuff comes back at nd, the other 10% comes in under 100 my limit is 1000ppm but my lab owner is very adamant about keeping solvent levels at zero across the board.

So it’s definitely doable but it’s very hard to not have some terp loss getting under 100

I wonder if it would be effective to dilute a butane extract with ethane and then purge off the ethane to allow the butane you extracted with to readily evaporate along with the ethane. The ethane, having a much lower boiling point would be much easier to get to ND levels.

First name to pop in my head is Extractioneering

Terps lost is exactly what my concern is with, specifically light monoterpenes. My thoughts are that it may not be worth the effort to do fresh frozen and other terpene retaining methods if your compliant purge will lose them anyway.

So the real question is not so much, can you make concentrates that meet the mark, can you make high terpene concentrates that meet the mark.

Just curious if you happen to know what the LOD is listed as on the COAs your man gives you?

given the nature of the market, isn’t the question how to make the highest terpene concentrates you can while meeting said regs?

folks will either miss the cut-off, or they won’t. isn’t the object of the game to be better than anyone else who has a passing grade?

Sure, basically the same question IMO. I suppose my thought expirament of the thread was intended more to be on the feasibility of these PPM limits themselves rather than a greater look at how to make the best concentrates.

In states like MA I think, at least to some extent, the ppm limits certainly fire up competition that’s for sure.

As macho man randy said “the cream will always rise to the top”

My live resin terp content usually ranges from 5-10% at the ppm levels i said above0 for most upto 100. I can’t find the nd level, I’ve looked everywhere, I will email and I will report back.

Yes this has been effective for me. Obviously don’t turn it up too hot or you’ll decarb, it really only needs to go up a little until you stop seeing any bubbling.

I was more talking about the rapid cooling part of your process. Is it just for the purpose of saving the extract that you’re cooling it down or is there something not obvious happening?

You don’t want any extract at temp for too long, just limits the time it’s at temperature. You don’t want any thca to decarb. If you’re going for shatter it’ll also keep it stable for longer in my experience.

Call Precision and we can get you dialed in. We regularly teach clients how to retain 15+% terpene content while simultaneously receiving RSA results under the LOQ in all regulated markets.

We are seeing this here in Michigan but with vitamin E acetate regulations. I happen to know one of the lab directors who worked with the state in prompting and figuring out these regulations. It starts by identifying the problem, where it came from, and whether or not the findings can be applied to a spread of products from the same market. For example, if the mystery peaks on the chromatograms from samples in question are seen in more than just one sample then it can be added to the list of things to identify and regulate.

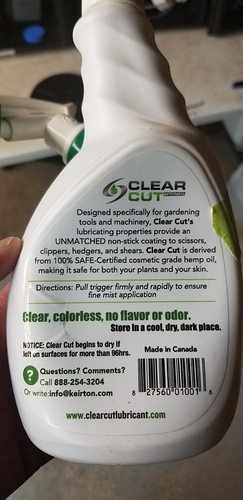

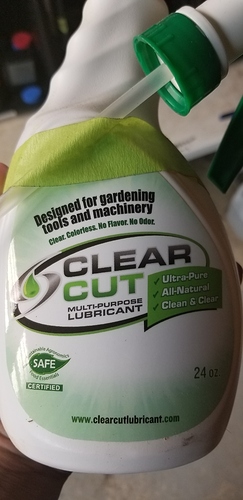

I expect you would begin by looking at what most people are spraying their machine trimmers with to keep them lubricated. Maybe the companies that make these things supply the lubricant which would be a good place to start? Then start to build a database of what people around the country are using and develop standards to test for them. The vast majority of mystery oils - in my experience - come from lubricated machine trimmers

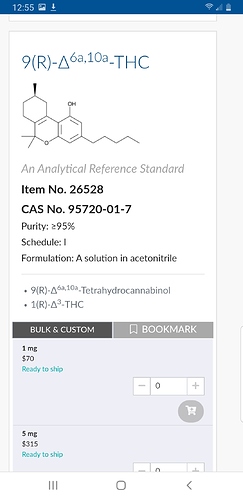

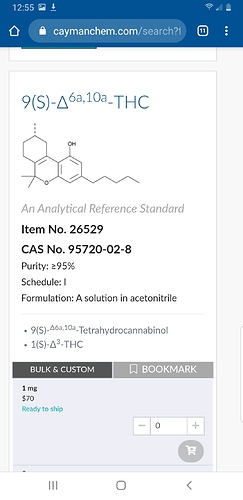

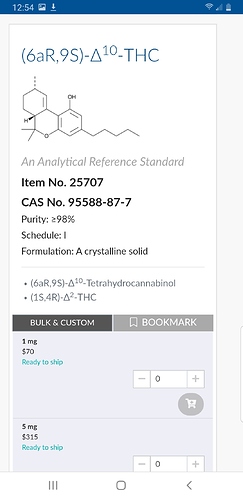

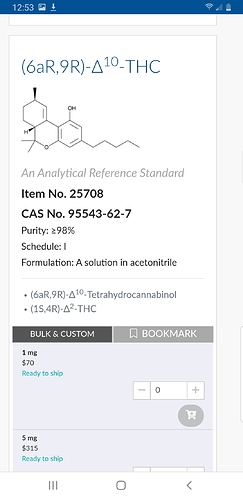

This is incredibly difficult as we are still discovering new cannabinoids. Also - to my knowledge standards for things like D10 THC and other cannabinoids aren’t widely available yet

@Kingofthekush420 where do you get d10 samples from?

I heard Cerilliant had a D10 standard, but a quick search did not locate it.

Might be something you have to call on.

@AlexSiegel should also be able to respond.

Bumping this to see if anyone else has thoughts on quality live BHO passing residuals @ 1ppm.

Considering taking a job where hydrocarbons are the only extraction in MA for strictly fresh frozen of outdoor material…