Hello,

First off, thank you! The information and help I have received through this community has been inspiring. Thank you to everyone that has provided a wealth of information and passion for knowledge.

Now to the down and dirty://

I have a product I have been working on for some time now and I cannot find a solution.

I am in trials for producing a 2oz, 50mg Nano THC beverage. I know…high dose/low volume can be a challenge, I’m persistent though, very keen on figuring this out!

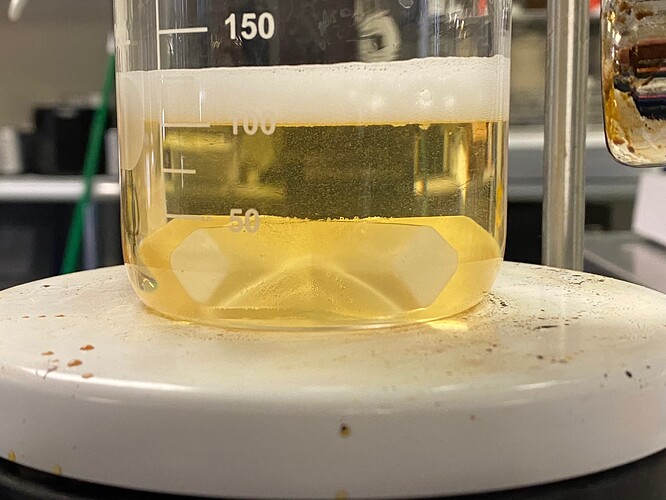

I have tested and produced numerous working stable nano emulsions ranging from ~25nm to 250nm. The problem for me lies in making a palatable beverage.

Beverages taste excellent at lower doses/higher volumes, 2oz is proving to be tricky though!

The Deets:

I have successfully created NEs with multiple surfactants (65% quillaja extract, Tween 80, liquid lecithin, powdered lecithin, Stuph, cannasol nano optimizer)

The NE concentrate(pre-dilution in final bev) has been taste tested from 20mg/ml up to 50mg/ml

I have tried maybe 7 bitter blockers with zero success including: MagnaBlock, MagnaPharma, ClearIQC100, ClearIQA500, 1,3 propanediol).

I have tried NaCl, glycerine, sucralose, monk fruit, erythritol, plain sugar, stevia all barely suppressing bitterness.

If anyone has any advice on bitterness suppression for 50mg 2oz drink, I would love to talk to you!

Possible Solutions:

-

Cyclo-dextrins: Have read literature describing the mode of encapsulation with certain cyclodextrins can block the bitter notes.

-

More effect combination of sweetener and Bitter Blocker

-

Specific fractions of lecithin that suppress bitterness

-

The cannabis gods come down and bless me with an answer, ending my perpetual torment.

Thanks again everyone!