So i’ve been reaching out to companies to get a better understating on certain steps in the rosin production and the reasoning behind it. But so far I haven’t received any responses yet.

This info is for my senior seminar presentation at my college. If anyone wants to provide any input on the questions below it would be greatly appreciated.

- I know you guys prefer fresh frozen to stop the loss of volatile terpenes. And to stop the decarboxylation and degradation of cannabinoids.

-Do you use flash freezing to prevent large ice crystal growth and the puncturing of the cell walls?

-how is it stored and packaged when waiting to be processed? Is it vacuum sealed? Stored under inert conditions?

- Pre wash processing

Are the flower heads broken up at all, to prioritize extraction yield, or do you try to keep the structure intact to prevent the extraction of undesired compounds?

- Washing time and temps

-I assume you try to keep the water in the washing vessel as cold as possible to prevent he loss of volatile compounds and reduce the extraction of undesired compounds. Are their any other reasons besides that?

Or do you guys have a desired wash temperature?

-Do you employ a soaking time for the biomass before applying any agitation to “relax” the plant structure, and reduce the amount of breaking that occurs?

-Is there a standard washing time with agitation or is it strain dependent? With a balance between, trichome head yields and reducing the amount of undesired extracted components?

5. Filtration

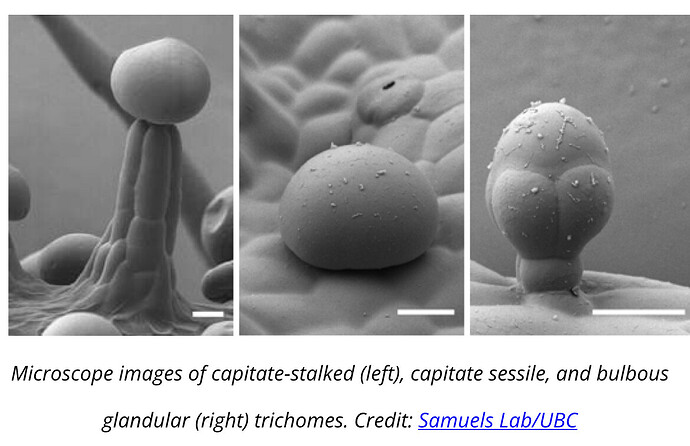

-Do you guys prefer nylon micron mesh bags or the stack of stainless-steel micron filters? have you encountered or seen any damage to the bulbous trichome heads if using stainless steel mesh?

-Are vibrations utilized in the filtration step at all to promote the separation of the trichome head sizes to the respective mesh size in the stainless steel filter or bag stack? Or do you use more water flow to promote this organization?

4. Freeze drying after harvest.

-Do you run a standard set of parameters for all strains, Or do you vary vacuum levels, shelf temps, and time based on the terpene profile of certain strains?

5. Post freeze drying

-I’ve seen that people will usually break up and shake the trichome heads through a mesh colander after freeze drying.

-Do you guys use aerostatic separation at all, or do you find it is not needed at this point in the process?

- Pressing

-Is the primary purpose of this step to act as an additional filtration of impurities, and create a homogenized mixture of terpenes and cannabinoids?

-How is the set temperature decided upon in this step? Do you want to decarboxylate at this point, or is the temperature just there to aid in the flow of the compounds through the micron filter bags, and desired temperatures should be as low as possible, with out blowing out the bag?

7. Cold curing after collecting pressed rosin

-What is the primary function of this step? Is it to cause the nucleation of THCA out of the terpenes to achieve the desired consistency? Or is there another reason for this step?

8.processing for rosin carts

-From some journal papers that I have read they state that THCA crystalizes more readily than THC, and by looking at the COA’s for your rosin carts it shows the cannabinoid concentration is predominately THC, so decarboxylation is used.

-Do you prefer to decarboxylate under pressure from an inert gas minimizing the escape of volatile terpenes? If done under pressure does this cause CO2 build up in the extract

-Or is decarboxylation done under vacuum and the terpenes collected in a cold trap and mixed back in?

9. Vacuum forced nucleation of THCA for rosin diamonds

-I have seen some techniques that use low levels of vacuum that causes the terpene concentration or intermolecular forces between the compounds to reduce and the THCA starts to crystalize out of solution.

-Is this a technique that is employed anywhere in your process?