I’ve been working mainly with ethanol and am still learning the ropes when it comes to CO2. I’ve been seeing some machines with 5k psi+. If you’re running supercritical and keeping densities consistent by varying the temps, whats the difference between running a machine at 2200psi vs 5000psi? Is the throughput higher with higher psi and equal densities? Or is the idea to give you a broader range to achieve the same results?

Thanks!

I was always curious what would happen at 5k psi and subcritical temps.

The CO2 gets pretty viscous actually but if the grind is fine enough it works great. Check out the densities at like 10ksi and 50-60f

It gets more viscous at 10kpsi but arent you just pulling more waxes as that point?

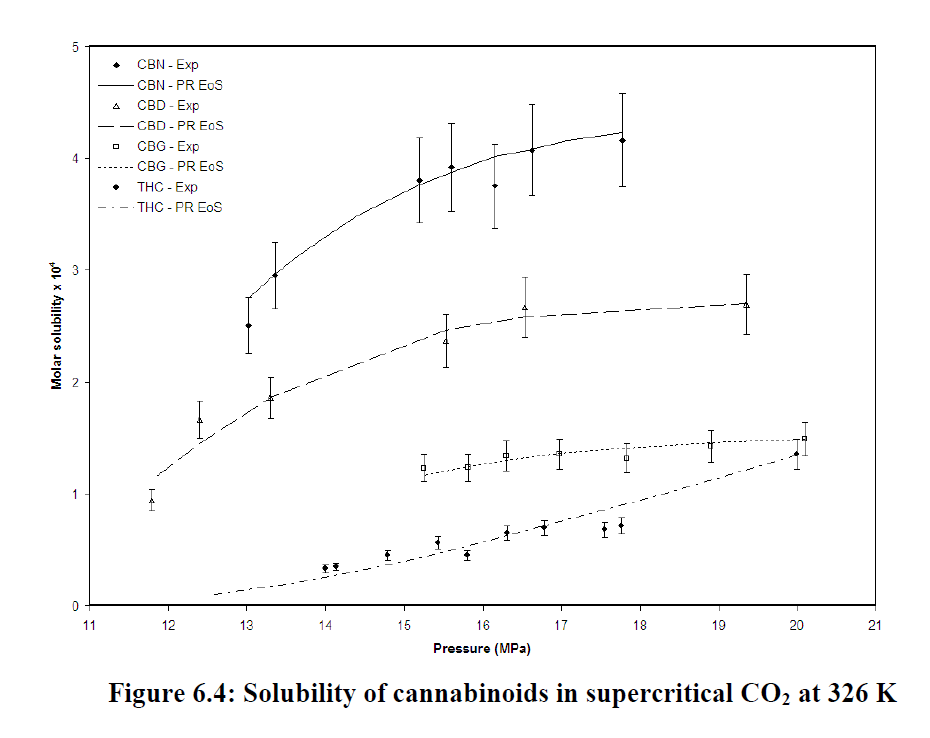

At a certain point flow rate becomes more important than CO2 density. For example, looking at the data from Brunel’s excellent thesis (Sustainable Production of Cannabinoids with Supercritical Carbon Dioxide Technologies), you can see how the solubility of each cannabinoid begins to level off as the pressure increases.

Honestly not sure why anyone would go beyond ~3600 psi for supercritical extraction. At that point every cannabinoid except for THC has essentially capped out solubility. While you could potentially increase THC solubility another 30-50% by going to higher pressures, you’re going to ruin the quality of the oil due to all the other crud extracted at the same time…

From my limited understanding, I believe you need higher pressures to achieve higher flow rates on your pump.

You could clean up the crude with refinement steps, no?

Depends on the type of pump. For positive displacement pumps (such as a diaphragm based air driven booster), the flow rate depends only on the input pressure and the rate of reciprocation (determined by the drive air pressure). So for a given input pressure and drive pressure, the flow rate will be the same whether the output pressure is 1000 psi or 10,000 psi.

You can certainly clean up the crude with refinement steps, but I think a lot of folks look to CO2 extraction for its ability to produce nice looking full/broad spectrum oil which does not require further refinement beyond winterization. If you’re extracting at very high pressures, your post winterized oil is going to be dark and full of crud you don’t want to load into something like a vape pen (i.e. chlorophyll, cell wall material, ect.), more like what you’d get from ethanol extraction. But yeah, if you’re taking your extract to distillate or isolate, then the quality of the raw oil doesn’t really matter.

I ran supercritical CO2 extraction for a year and a half and agree with everything you’ve written here. The original recipe the facility was using when I came in was something like 3500 PSI at 50C with 500 grams per minute on the flow rate. The result was a very complete extraction, but one that was super dark, waxy and even after carbon and winterization would produce a full spectrum oil that looked like Coca Cola when carted up.

I worked with this machine a bit and had much better results with a recipe between 2200-2800 PSI at 50 or 55C with the same 500g/m flow rate. Overnight I would run it with a lower flow of 200g/m, though I’m not sure if this changed anything.

The real magic bullet here was in the pressure gradient at the collection vessels. The machine was a Green Mill Pro and had three collection vessels that could each have their pressure and temperature set independently. Through these settings we were able to achieve a terpene fraction very similar to some of these longer subcritical runs I’ve seen people using, while extracting our cannabinoids at the same time. The first vessel would catch most of the color contaminants as well as a large portion of the waxes etc… we would process this for distillation, the second vessel would be a very potent yellow fraction… we would winterize and decarb this material and then add the terpene fraction back into it for cartridges. This produced a cart with similar potency, appearance and terpene content as the live resin or sauce carts on the market here.

The point of all that noise was that though the machine we used was capable of 7500 PSI, real quality and improved throughput came via much more modest pressure and the ability to change density in between collection vessels and separate our fractions.

Hello, I was wondering if you could point me in the right direction on how to determine what temperature and pressure to set my separation vessels at to fraction out waxes/cannabinoids/terpenes. Is this generally achieved through trial and error, or is there a chart somewhere showing what compounds will fall out of solution at a certain CO2 density?

Side questions: Would your method of collecting different fractions in each separator work even if separator vessels were vented after stopping the pump? Would turning the heat up in the separators (70C) after extracting to help with collection affect the quality of the cannabinoid fraction in any way?

the only thing that increasing temp in your separators is going to do is increase the likelihood of your extract remaining soluble in your decompressing CO2 stream and bypassing your collectors into your recycling system and probably contaminating your pump. if you’re looking for a starting point for separator parameters the 2017 study titled “Supercritical carbon dioxide extraction of cannabinoids from Cannabis sativa L. plant material” by Rovetto & others will give you a jumping off point. Every system is slightly different, and because the solvent in question has such variability in density and solvating properties with respect to small changes in temperature and pressure you will definitely need to do some experimenting to determine adequate operating parameters for your system.

See:

Edit: just realized this was a response to @CuriousExtractor in another thread.

Co2 is one of the lowest viscosity solvents you can find.

What extraction solvent has a lower liquid viscosity?

Don’t waste your time thinking you can separate anything with resolution by the function of cyclonic separators.

This has been and always will be a giant waste of time…

That would be highly dependent on the temp/pressure. 10ksi CO2 at 0C is certainly more viscous than at 1200 psi.

Just got your PM, I don’t get on here much these days. Youve probably got this figured out now. I cant find my written copies of the last recipes I was using, but I believe I was running densities around 0.55, 0.30, 0.12 (should drop to subcritical) respectively. Fine tune that. The idea was to sequester as much of the brown trash in vessel 1, catch a wide and complete yellow cannabinoid fraction in v2 and the terps in v3.

Vessel 1 and some of the vessel 2 material would go to distillate. The remaining v2 material would be winterized, carbon scrubbed scrubbed decarboxylated and mixed with the terpene extractions from vessel to make carts.

I may have already commented in here, but based on the potency of v2 after winterization, I think running that material in the short path would finally have gotten us a potency that matched the clarity and color of our oil (an issue I never had running hydrocarbon extracts into distillate)