I was curious if anyone uses liquid nitrogen (or knows of others) to chill down condensers for recovery pumps (specifically Corken thinking a tube and shell where the nitrogen is fed via bottom jacket and the top left open for venting) if that makes sense. and same idea for chilling the propane/butane before being fed into the CLS? had a consultant that WE WERE going to work with that sweared by liquid nitrogen but i was always hesitant due to gaskets failing and the possibility of freezing the hydrocarbons to a slush/solid state propane freezes at -188c and butane at -138c liquid nitrogen being -195c…

gray wolf used it for his jacketed coils exactly how you said

I’ve been in the same boat debating between gl building a cryogenic generator to make my own LN.

You have to make sure as you stated the seals and metal can handle these shocking temps.

I’m honestly probably going to make a LN circulator with silicone fluid that can handle -120. Setting up a system where the LN is regulated to maintain temps.

But super complicated and I’m already over my head with the type of SPD I wanna run.

Ok back burner, will update when I do get around to it.

I think direct LN will cause more headaches than solving. But using it as a chiller might be cheaper than electric chillers.

Liquid nitrogen doesn’t have the same cooling capacity as dry ice. Sure it’s colder but dry ice has more energy in it then liquid nitrogen does.

I mainly want that LN temp for terpene extraction. But that’s about it, DI is surprisingly pretty good for all my needs.

Found a local vendor for .50c a lb. So wallet burn doesn’t hurt as much.

But this is off topic and mainly want to direct the discussion back to CLs.

Previous discussion…I think this should be merged with previous post.

I used it before exactly the way you describe. Would I do it again? Not sure. Probably would rather look into the magic of a trx valve and direct refrigeration. I’d like to see a propane based chilling system because why not. Where’s @downtheterphole when we need him

Love mine. Im all about cutting out consumables, being able to flip a switch and have instant condensing power is great. Also it was cheap.

I’m not sure how it works with triclamps and extraction equipment, but in oil and gas cryo processes all had special studs(L7) and gaskets

@FicklePickle @greggoose710 liquid nitrogen is waayyyy cheaper in my area versus dryice (believe we pay 75cents per lb) from Praxair versus using 100-200lbs dryice perday mainly look for cost savings and our 150amp panel single phase is already at 130amps so dont have the wiggle room for hubers or refergeriant chillers

Are you really drawing 150 amps of current though?

In the end if it makes sense financially then dooo it tooo it

Are you running active? You can eliminate a lot of that dry ice use most likely by staging your condensing a little better and taking advantage of some of the energy you already are putting into the evaporation side

@greggoose710 we have a delta cup15 and a stainless VKS 70 VTA along with transfer pumps for lenticulars and sock filtration @Apothecary36 yes active we use DI currently but trying to get away from it since the VTA can utilize liquid nitrogen as well

You plan on running both at the same time?

@greggoose710 we also have vac ovens and rotos with chillers haha we already juggle the fuses as is along with a water heater for the CLS and a 10liter SPD setup so were pretty maxed… we want a falling film but held up on it due to the same thing- limit of amps. we usually do all the Etoh extraction/filtering/rotoing on one day then VTA/CLS on the following. ovens on always usually

Get rid of the electric water heater and go with propane

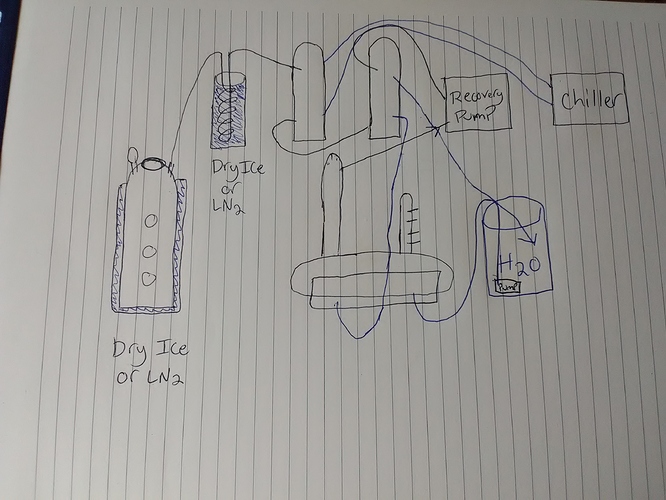

I’ve chilled my LPG injection and pump discharge using dry ice slurry with alcohol mixture and a tri-core heat exchanger.

I’ve used LN2 to chill LPG injection using a counter flow heat exchanger and cooled the pump discharge using a -15C chiller and a counter flow heat exchanger.

LN2 chilling is easy with a counter flow HEX, albeit noisy.

Why not just use liquid co2?