What about tooling? Sep funnel vs. Stirrer? Gas blanket/atmospheric? Rotovap vs. BF?

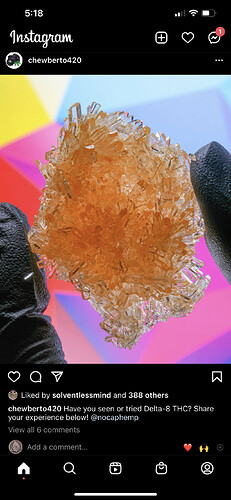

Lmao i didn’t think this shit got worse ![]() let’s play guess the cannabanoid

let’s play guess the cannabanoid ![]()

Nvm it got worse

@moveweight your two favorite things in one delta 8 & rosin

Pine rosin extracts. This is a great look! Can’t wait to see some people foam from the mouth

I’m just sad it was a picture posted by a very nice & reputable photographer

![]() that’s gross

that’s gross

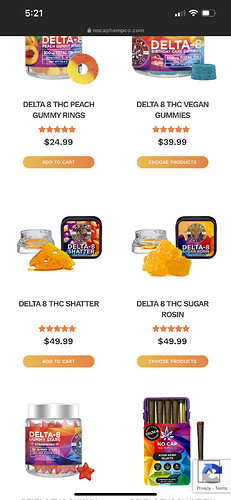

Marketing chads at their best ![]()

I can smell the paint thinner from here. Gack.

PTSA monohydrate yields the best results imo; HCL is great but its not as selective as PTSA, HCL usually yields around 10:1-8:1 d8:d9, and thus is not a very good route for compliant material; the Hydrogen chloride yielded from such a reaction can also be a pain to wash out, and its formation also adds a minor extra layer of danger to the operation and requires gas scrubbing infrastructure to be completely “safe” for the operator.

Id say heptane 2:1 by weight Hep:CBD - PTSA 1% by weight - under inert atmosphere

We can either run this at or near reflux for 30 mins -1 hour; for a quicker reaction, or RT at 12 hours +

(im very open to debate about the reaction time here)

MONITOR THE REACTION WITH TLC

hit with 4 wash cycles 1:1 by volume reactionary solution: Distilled water

first wash; Distilled water, Sodium bicarbonate, pinch of non iodized salt @ 40c pH 9.5

2nd wash; Distilled water, Citric acid, pinch of non iodized salt @ 40c pH 6.5

3rd wash; Brine wash - Distilled water non iodized salt 5% @ RT pH 7

4th wash; distilled water only @ RT pH 7

then proceed to drying the azeotrope formed when washing heptane is around 12%, I always use sieve for this; but many ways to skin the cat here.

Proceed to column refinement filtration, i usually pack my columns with (from bottom to top) sintered disc - Filter paper - compression ring[holds down paper] - silica gel[catch fines] - B80 - T5 - AC[Powdered] - AC Granular - Activated Alumina

run the biggest column you can; be sure to flush it after everything has been filtered as well; i usually keep the flush seperate from the primary filtrate.

Its also important to not “overload” the column by filtering too much solution through as you will begin to elute impurites.

proceed to solvent recovery

proceed to distillation.

imo; distillation via WFE is superior to SPD with converted materials; but if done via SPD you need to pull as deep as you possibly can, maybe a nitrogen sweep is in order as well. I feel that low and slow distillation is ideal here, but maybe not, maybe hotter and quicker is; open to debate here.

everything must be inerted; solvent should be sparged; reactor should be baked out before the reaction; Prep work is is absolutely required.

Inert set ups should incorporate Schlenk line philosophy, gas trap bubblers should be incorporated on the vessel gas inlet and the vessel gas outlet. these bubblers should be filled with pure unscented mineral oil. Gas flow should be regulated. there is much debate between n2 and argon; argon is superior imo.

thoughts? what else can we incorporate besides prep chroma to further ensure purity

Material prep: make sure the isolate is thoroughly dewaxed and has minimal impurities. People buying cheap iso should probably consider re-winterizing because lipid content seems to be fairly common and even at 1% will probably contribute to side reactions. ReX to be 2-4 log purity might be overkill but it might also be the difference between needing prep chromatography and not

yes excellent point; MeOH test you isolate before you all buy at the very least! This is also an excellent example of why having internal analysis is super important!!!

i usually reX any stuff i get thats way off color; its important to have a good vendor tho.

Agreed for sure. Testing the input as it’s actually being run and not just using the COA from the MFG is always a good idea. Also important to make sure that the supplier informs you if there is any change in the production process ahead of time so you know when to look closely. In house also makes it a little less painful to test in duplicate/triplicate and assess batch homogeneity

Would it be sufficient to run the heated circulator at 150C for 2 hours for this?

Sop for baking reactors is 2 hours at 200 C

But 150 C for 3 hours should do it as well

Place a heat gun on parts that are not exposed to the jacket but are exposed to the solution

Would an acetone bath accomplish much the same thing?

No acetone does dry and quiete fascinating that it s a standard solvent used by pro chemist for this purpose but by no means dry enough

I would think mol. Sieves dry alcohols like ethanol and ipa be an even better choice for it s azeotrope property s

But none of these shortcuts compares to hightemp, hard vac , long time drying

Our isolate is consistently pure

I think my partner Mike is selling iso 10 packs for $350 per kilo

Anyone interested hmu and I’ll send you his contact info

Thank you @RockSteady for these insights

On behalf of the community I am writing the RT sop and will post ASAP

As for all members that have any info on the

Diffrance of quality of N-heptane

In technical grade versus lab grade please post it for I have not been able to find much and would like to

It would appear the fisher’s technical grade COAs leave something to be desired:

H20_205990.pdf (51.4 KB)

Thx for the effort

Indeed not very thorough ![]()

It was colorless so it passed ![]()

Wtf is the use of such test ![]()

“is it heptane?”

“Looks like it”