thank you, I’ll look in to it.

On the 3/8 & 1/2” tubes it’s .049” wall thickness and I’d imagine, but have to check with the boss, that the same would work for 3/4” and 1”

The 3/4 od should work in a 3/4” emt shoe and the 1” should work on the 1” emt shoe, you should be able to rent the bender from most tool rental spots.

What weren’t you happy with? Care to elaborate? What changes did you make?

This was back in March. I will for sure have to see you when I come through again

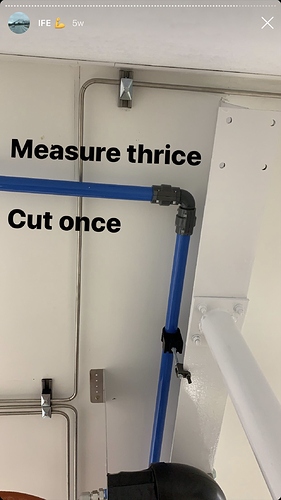

Electric conduit done RIGHT! Damn. Nice work!

Thank you, but it’s actually 1/2" .049" stainless tubing. A little tougher to work with and get dead nuts correct than nice easy soft conduit that you can bend against the floor with a conduit bender. These i check every 90 with a square to make sure its actually straight and doesn’t dogleg 2 degrees for 15 feet of bend.

The ceiling is full of: nitrogen, vacuum , hot water supply and return, hydrocarbon vapor from collection to molecular sieve; hot gas from pumps to material column, recovery pumps + passive path to heat exchangers.

Keeping things level was a pain with 20 footers solo

Cleeeeaan! & Proper! ![]()

![]()

What haskels are those and what kind of recovery numbers are they hitting during normal operation with butane or butane blends? I’ve only used the EXT420’s and the 420-2, i like them but always thought they were going to come out with something a little better.

Dual Cup 30’s?

daamn, the only balls are dead balls in your build ![]()

![]()

![]()

AGD 1.5 Gas Booster. They’ll pump however much vapor they’re supplied with. A single one will do north of 2 pounds a minute. I’m not sure where the curve starts to flatten yet. I’ve been working on a different job site in California this week and won’t be back to Tacoma for another two weeks.

In my experience the pump’s never been the limiting factor.

How much heat energy is on your boiling flask?

I have the columns insulated on my beest, definitely. I take them off occasionally, let them dry out, and wipe everything down.

@710ST I am going to make fuzzy fleece wraps that go over the insulation and make it look permanently frosty. Going to have it lace up the inside to keep hidden and easy removal, for cleaning and install.

I wouldn’t suggest using fleece as it readily generates static. They do make anti static fleece though so that may be something to look into.

Perfect, and thank you for that. Even thou my system is bonded, I definitely don’t want to have anything that can cause a static discharge.

I only suggest the fleece because it would look like frost. And as 710st said and I also know from personal experience, Boris loves the frost build up. I thought it would look nifty having the asthetic effect of it being there, without actually having it and to clean it up.

But, I will look into this

Looks cool (non insulated) vs function (insulated)

I will go with function.

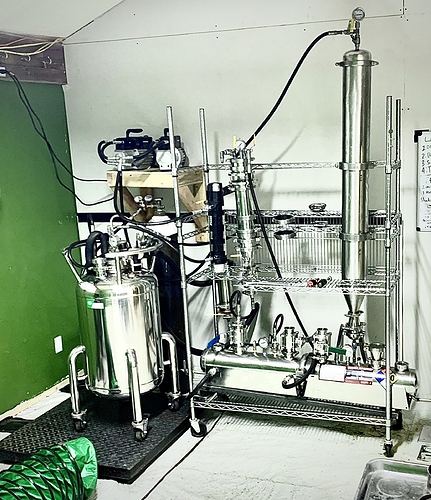

Expanded again into a dual 6”x24” horizontal collection pot system (6”x48” total collection capacity) and put a 6”48” choochoo train material column on top to match. -40c/20L chiller ported through wall behind system. Ported water bath with twin Sous Vides. Industrial floor scale to monitor solvent loss/usage.

10lb material column allows for consistent pours of 450g+ with a 2.75hr start-to-finish run time. Utilizing Nitro to slowly push until darker chlorophyll begins to hit the CRC, now only modestly filled with B80 and a cake of Celite on the very bottom due to fresh biomass influx.

Parallel TRS21 setup still rocking while waiting for MVP Viton diaphragms from Bhogart who says ptfe are the only way to go…![]() Gotta pet theory that the PTFE diaphragms’ brittle nature makes for a more sustainable parts-replacement economy for Master Vapor, but whatever.

Gotta pet theory that the PTFE diaphragms’ brittle nature makes for a more sustainable parts-replacement economy for Master Vapor, but whatever.

Look into cryogel. It’s a subset of aerogel (it’s silica gel that has had water molecules replaced with air)

You can buy rolls of it on McMaster Carr.

With some research you can find ways to permanently insulate so that moisture doesn’t seep behind and you don’t have to maintain it.

Edit: Here’s a quick video on the installation of cryogel on cryogenic piping at a refinery. The video opens with the commentator saying “insulation of cryogenic piping and equipment presents some of the most technically challenging work in our industry”.

And its true–insulating “cryogenic” or very very low temperature piping and equipment is HARD to do correctly. $0.02

You definitely want PTFE seals and diaphragms…ESPECIALLY on gas recovery. Those terpenes that make it past the sieve have a tendency to rip FKM (viton) up after a while.

Speaking from experience.

hey @Dred_pirate I am located in the Phoenix area and seen u replied to a post about possibly coming out to teach or show me how to properly run my extradition equipment? If so I have a 10lb BVV with MVP pump… I’m out here from Cali but instructor could not make it this week… Please let me know and we can talk about compensation. Thank You

Ldiaz420247@gmail.com

I sent you an email just now