Shes a shop kitty until next month. She was MIA for like 2 or 3 months. Well now I’m in between houses and working on scoring a warehouse and she re appears. Didn’t know what else to do with her besides shop security and therapeutic needs

do you have to make many adjustments to the equipment or procedures to extract in such a low temperature and pressure environment?

How does that setup work in zero gravity?

thats the easy part. He spins it

![]()

![]()

Looks fantastic brother!!!

is that middle column your remediation column/

That’s the material. But I can use it as a jacketed pre heater for that purpose. I can use the big one on the right as a large live resin column, then warm the solution to go through the media, and into the collection to he recovered

Gotcha do you typically preheat prior to filtration?

Man that is a sweeeet set-up, without giving away too many secrets. How do you monitor your gas out-put? Inline gas meter or a scale?

Some of these set ups are absolutely wicked! I wish every piece of equipment was labeled what it did haha. Nice job guys, wow!

Is that a modified rainer system from OSS?

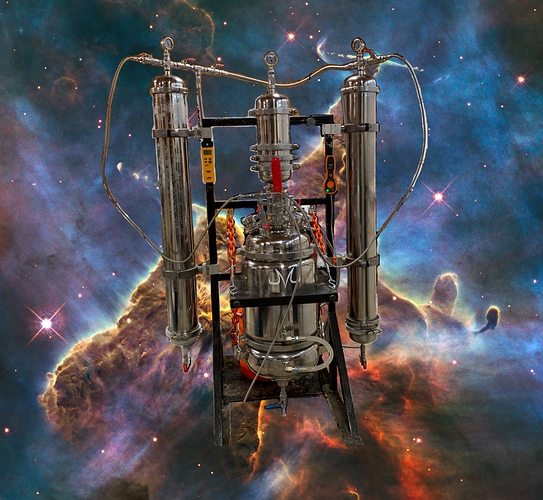

ExtraktLAB 140 model.

Heated vessel jackets.

Terp trap in back.

C02 Recycler.

C02 Safety sensor.

Pressure monitor/auto pressure capacity shut off.

Inlet/outlet temp sensors.

6 to 7 kilos per vessel depending on bio mass grind. Supposedly it can fit 8 kilos per vessel but I’ve only fit 7.4

What size chiller do you use for one of those ethanol collectors?

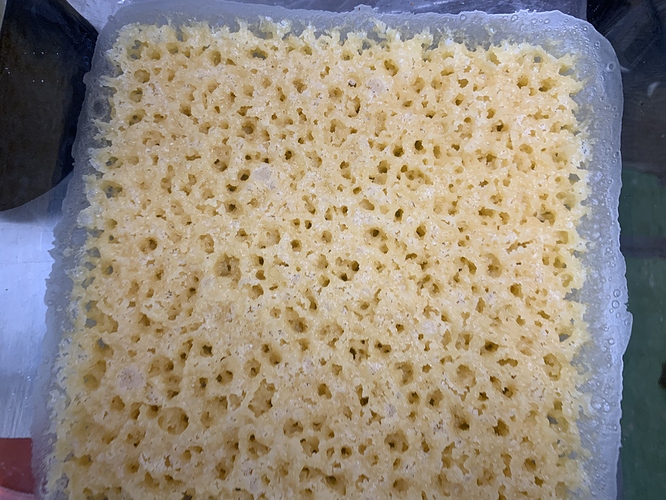

What kind of consistencies are you guys making with co2?

Wow that is bad ass