Everything… I think:

(TC = tri-clamp)

- 8" x 24"Jacketed Spool - 20L

- 8" Lid - 5 x 1.5" TC, 2x1/2"BSP Female, 2x1/2"BSP Male

- 8" Lid - 2 x 1.5" TC, 1x1/2"BSP

- 8" to 1.5" Jacketed Bowl / Reducer

- 8" Jacketed Splatter Plate / Flat Bottom tank. With folding handles. Jacked surrounds side * Bottom for more accurate temp control.

- 2" x 20" Jacketed Condenser

- 8" Filter Plate with internal ring

- 20" Cartridge Filter with 1.5"TC in/out. Uses 226/Fin filter sizes up to 20" Also has legs.

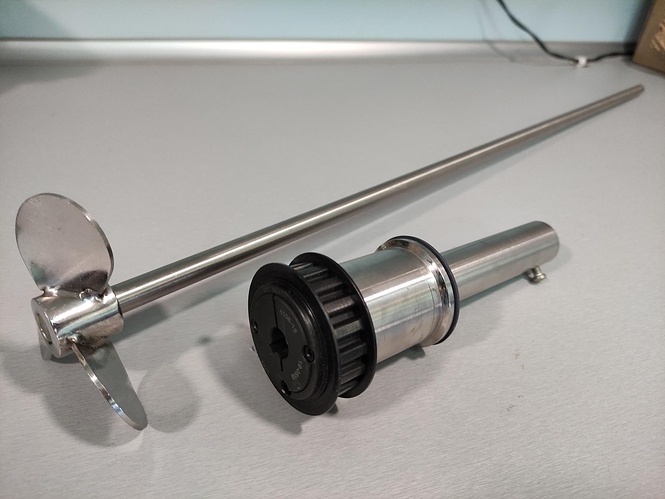

- Vacuum Rotary Feet Through Shaft - With propeller -

- DC motor controller & belt etc

- 1 x Bichman RipTide Pump

- 2 x 1.5" x 6" Sight glass

- 2 x 1.5" Sight glass for lid

- 1.5" TC x 26" Thermometer dip well / Thermowell

- 2 x 1.5" Multi-position, locking ball valve - stainless

- 3-way T Port ball valve 1.5" TC

- 1.5" TC rotating spray ball

- 2 x 2" to 1.5" TC Reducer (for condenser)

- 2 x 1.5" TC 45 degree Y

- 2 x 1.5" TC 90 degree bend

- 1 x 1.5" TC U / 180 degree bend

- 2 x 1.5" x 6" straight spool

- 5 x 1.5" Blanking caps

- 4 x 8" TC Clamps

- 25 x 1.5" TC Clamps

- 2 x 2" TC Clamps

- 4 x 1.5" High Pressure TC Clamps

- 4 x 1.5" TC to 1/2" BSP Female + 4 x Male

- 4 x 1.5" to 1/2" Hose Barb + 4 x 1" Hose Barb

- 3 x Rubberised mounting clamps for 8" spool - 10" Clamp

- 2 x Rubberised mounting clamps for condenser + 2 for filter housing

- Viton gaskets for everything + lots of spares.

- Mixture of 1/2" BSP ball valves, adapters, 90s, Ts, air connectors etc. Loads of bits, 20 - 50 pcs probably. All stainless.

I dont want to get in trouble trying to sell something in the wrong area but if you’re interested it is in the classified on here already: Stainless Jacketed Reactor, Condensor & Filtration System + Loads of Extras For Sale

Thank you for all the kind words, it was a labour of love for sure. I’m in the UK and sadly the law and covid has forced our business to change so its no longer needed. Months of design and manufacture and I only got to use her 5 times ![]() ! I’m still to scared to add up what it cost me …

! I’m still to scared to add up what it cost me …

I will try and dig up some of the CAD files for the rotary feedthrough but it was mostly drawings on scrap paper in the shed ![]() but heres some close ups of it.

but heres some close ups of it.