should liquid flow through tis easily or just real slow without pressure or pull

thanks sorry if its redundant

Loling

If staged right. It should flow fast.

Looks like it could use a good cleaning

I think it’s just dirty, there’s little specks all over when you zoom in.

like if I just pour iso over it … it should flow fast? Yes im a idiot hahaha whatever , i used it once without a recovery pump below a 6x4 inch inline packed with d.e. and activated carbon , i didnt use fiklter for catchingthe wax from the dewax sleeve and half stayed in the filter… now after soaking in iso to clean the iso gravity feeds through slow as helk…

I guess Iam asking if i poured ISO over a nex 1uM welded will it flow freel ?

thanks I only used once

without a tampon to catch wax

Yeah, don’t put powders directly on your sintered disc…

Big no no

That’s definitely your problem then. The disk will slow flow a bit but you should have a steady stream coming through. Probably needs more than just an iso soak. Baking before soaking may help if you don’t have access to an ultrasonic cleaner.

That would all depend on what you are trying to flow through it, such as the viscosity, particulate level/percentage, pressure being applied/flow rate. Many parameters would go into what kind of flow you can expect. Thanks, gregh@heyesfilters.com

I’ve done it for months

Hey, if it works it works. Just heard to many stories about clogging for me to want to try it.

Sorry for the late gratitude.

Thanks for replys very helpful

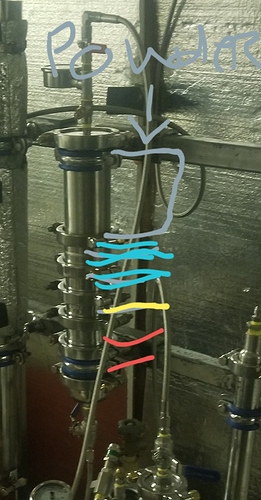

the ttop in purple is powders…next is blue lines that shows paper filter , 2 filter plates w drop in extra plate and ring for both…i stage the papaers …20um on top 2x…next fikter plate has 1x filter papers w 2-4um…then yellow line shows tampon depth filters in one whole filter plate

…next the red line is my 2 welded disk…a 5um and 1um…staged down to 1um. and properly staged before ur welded disk it should glide through

powders never see my welded disk

i even put more tampon below the last welded disk in the hemi cap w more drop in rings and plates

hope ppl catch on to this…i overkill but never has any powders got into my medicine

i have 6.prefilters before even getting to a welded disk. thats how u do it right and w ur customers in mind