What do u mean extra heat? U have extra heat on it besides the heating bath?

Ambient temps are 20C, and i can put fridgerated solvent in the roto and still get it to “boil” over with the vacuum depth im at.

I can definitly push it harder with the bath temps, but i like to keep my oil preserved best i can. I definitly noticed a difference in oil quality between 40C and 60C when recovering my alcohol,

Extra heat from the bath. Lets say at your vacuum level your alcohol evaporates at 50c. 50c isnt going to be enough heat to force the vapor up the arm of the roto to the condenser. You need atleast probabaly 60c to get proper recovery speeds. This is just an example.

At my vaccum depth, 7C is the boiling temp of water. I think im well over 10C over. I totslly understand what your saying, but im not sure how its supposed to help me

Youre recovering ethanol correct? At max vacuum ethanol boils at 34c. Youre not at max vac and are only at 40c. I don’t think thats enough heat, i think you can get better recovery upping your bath temp is all im saying.

Im confused, wats max vaccum to u? I can put room temp (20C) solvent (ethanol or heptane) in a flask pull vac on it and it will boil

How does alcohol evaporate at room temp when u leave it out?

Liquids evaporate because the molecules are always jostling around and are going to end up getting kicked off the surface of the liquid. Basically when you have a liquid like water or alcohol, it wants to stick together (due to hydrogen bonding), but it’s also getting bombarded with air molecules and if it’s warm, it will also kick off more molecules. If an air molecule can hit and break off a molecule of alcohol or water, it’s going to take energy to tear that bond that alcohol and water has with itself which slows things down thus lowering the temperature.

When you evaporate youre actually cool your heating bath because of how evaporative cooling works. Max vac is -29.92 mmHg, at that vac level alcohol boils at 34c. At 8000 microms like youre at i doubt youre even hitting ethanol boiling point (because of your bath temp and vac). This means your not evaporating as efficient as you can. Liquids will ALWAYS evaporate as the molecules are in motion, with heat you can speed this process up.

Max is -29.99 i think. My needle guage tells me im at -29.5. You had it at -27 and changed it

Either way i think you get what im saying

That’s a great recovery rate for a 20l roto, do you have your rotovap optimized with some tricks from that thread?

My 50l isn’t even recovering that fast, I have a leak on the one PTFE gasket that’s on the joint to the 20l receiving flask(looks like this one

and waiting for backup set from lanphan and plan to swap it out with one of the rubber looking gaskets that’s on all the other connections.My vacuum level tops out around .08 MPa according to the gauge.

I run my water bath at 80c to compensate for this leak and and have chiller set to -20c and it seems to stabilize around -16c.

I’m wondering if fixing this leak and running the water bath at lower temp with help with my recovery rate dramatically.

Who did you get your 20l rotovap from? I’m thinking about selling my 50l and getting a new 20l if I can hit those recovery rates with a 20l instead.

Will be trying the rotobooster for sure. I saw a temp increase last night on my condenser -5L-

I have a 20 liter from lanphan. I usually pull down passed .8 to like .85 when i roto alcohol. If you fix that leak it should help with your evaporation speed, id go a little deeper on vac and back off on such a high temp. Try deeper vac and 70c and see how it runs, if need be you can increase your bath temp from there.

On a side note if you have a lanphan 50 liter like mine you should be able to hit the same recovery speed as me. The reason i got the 20 liter is because its more efficient then the 50. The only difference is the size of the boiling flask, the neck diameter is the same size which allows for the same evaporation rate. A 20 liters bath is 3k watts of power, a 50 liters is 5 or 6. Thats alot of amperage for the same evaporation rate IMO.

I can boil water on my stove at home at the #2 setting, if I want a pot to come up to boil faster or overcome some change in enthalpy (like dumping in cold ingredients and remain at or close to a boil) I turn it up to #7.

CFM absolutely matters if you are trying to run a team of multiple rotos off of a single vacuum pump (as I do).

For someone who is trying to play the part of “consultant” you sure don’t seem to understand “as fast as possible”.

We’ve done comparative tests, one 50L rotovap will absolutely take in more “tea” and recover more ethanol in an hour at 90C than it does at 70C, especially considering all my rotos have been fitted with liquid preheaters for the incoming side (as specified in a number of threads on here and elsewhere about optimizing your rotovap). The setpoint on the bath is not at all the same as the temperature of the liquid in the evaporation globe, with every bit of ethanol that is evaporating some cooling action is happening to the liquid in that globe. BZB and others making falling film evaporators have significant differences between their heating circuit setpoint and the max temps that the crude moving through their evaporation equipment is actually seeing. While residence time is significantly different between a rotovap and an FFE, the reason the temperature of the heating circuit doesn’t match the temperature where the evaporation action is happening is the exact same.

Also, your understanding of refrigeration power with regards to temp setpoints is straight up wrong.

Yes, most chillers have a point (for many lab chillers it’s frequently right around 0C/32F) where they have their maximum ability to cool, and it’s quite common that the maximum cooling power (expressed in BTU/hr or kW) at 0C is a multiple of the amount of cooling power the chiller is capable of at it’s max cold setting.

With that said, most lab chillers are only cycling the refrigeration compressor with an on/off signal, and if max cold is requested the signal will be set to “on” until that temperature is achieved, much like the thermostat for the air conditioner in your home. Once it hits the setpoint, it stops running (on my Chinese chillers both condenser fan and refrigeration compressor are run from the same SSR, so literally it stops everything on the refrigeration side).

If you set to max cold (as I do at -22C) the compressor will just keep running as long as the heat input to the system puts it a degree or more above the setpoint. From experience, with ambient temps around 15C the chillers refrigeration circuit will be running constantly as long as ethanol is condensing with a steady state condition at -5C, regardless of whether the temp setpoint is made at -6C or -20C the chiller will do the exact same amount of chilling “work” while it is condensing ethanol. The reason I set mine to a lower temp is to hedge against the roto fluid warming up excessively on days when my ambient temps get higher than 15C, it takes a lot of energy (“work”) to significantly change the temperature of water and my chillers are all running a 50/50 bath of glycol and water.

If thats not how cooling power works why would they give you a chart showing cooling power and watts of cooling power at a certain temp/loads at a cetain temp? Your chiller will not be able to cool as well at a lower temp as it will at a higher one idk how you can argue with that. You obviously cant read above i said CFM doesnt matter after a certain vacuum level, im sorry if you dont know this but its facts.

To confirm what water bath temp and chiller temp setting do you find works best for your 20l rotovap?

Edit - looks like you recommended 70c and -10c earlier in the thread.

Theres a point when pulling too much vac actually makes it harder for the ethanol to recondense since you’re lowering the boiling point so much. Lets use an example. At perfect vac ethanol boils at 36c, at -27 lets say its boils at 40c. If the cfm is the same then youre literally making your chiller have to run colder to condense at full vac vs -27. This also slows down your condensation time as it takes more time to cool. On my roto anything over -26 will make the ethanol run up over the top of my top coil because the boiling point gets so low. Youre literally cooking your ethanol temps at temps itll boil at without vac. Youre making your chillers work harder for no reason. Either that or theyre undersized like i said in the beginning ![]()

Its easy to notice this caveat when running pentane

Think about this:

If youre pulling full vac and your ethanol boils at 36c and youre heating it to 90c then your chiller has to cool it to 36-50 for proper condensing. You said yours runs at around 5 c? Not a big enough temp change.

I still dont know why ur set on the 36C.

This is from AI 20L page, showing ethanol boiling at 20C.

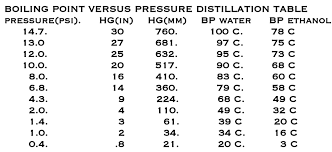

Here is a chart for the ethanol boiling point comapred to vacuum. It goes down to 3C on the chart but goes well below that.

I may be incorrect here as my roto experience is low but deep vac also can cause issues with the boiling off as well- the amount of vapor generated is only so much at a certain point in your solvent removal, as you remove more and more thanol from the solution it will cause invonsistant boiling and to bump and “pulse” unless you have sort of capillary tube bleeding in a line of nitrogen or other inert gas.

Deep vac ends up kind of pushing the last 5-10% of ethanol deeper into solution and making your system more inefficient- at least this is how it was explained to me by the guys at pope.