Hey Cyclopath, sorry for the lag. I saw ur reply after eating my nightly gummies, so I waited for clarity before replying. You asked a question head-long into my obsession!  I believe you are correct in seeing a 50% reduction in total oil in the first run. Fortunately, its easy to recover the losses in a second run.

I believe you are correct in seeing a 50% reduction in total oil in the first run. Fortunately, its easy to recover the losses in a second run.

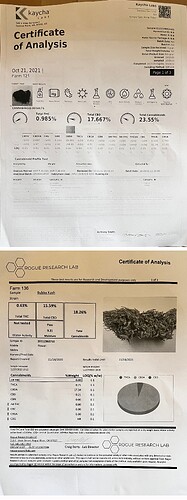

On this run, I used hemp product purchased from BuyOregonHemp.com and have the C0A. CBD is 17% with this strain. On losses, there are three points where this can happen:

First, I did a quick 30 second wash of the 2oz with 99% ISO at room temperature, poured the plant through a nut milk bag for straining, then let the bag drip-dry into the capture container. What’s left behind can account for upwards of 20% loss, to be recoved in a second wash.

Second place of losses - distilling with distilled water. So, the wash metioned aboves resulted in about 2 cups 99% ISO to be boiled down. I added about 1/2 cup of distilled water to this. This forms two emulsions. First being a weak water/alcohol emulsion that can gets boiled out when the water reaches 212f. The second one is much harder to break, and this is the phospholipid, IE, lecithin-like binding of water and oil. This is what’s left at 212f. The water can look clear, typically translucent, all the way to the worst case which looks like whole milk. The variable I have found is the plant phenol type and soak times. This goes back to @beaker 's louching. More on this below. What I am finding, this emulsion can account for about 8-10% ‘loss’ of oil in the first pass. This ‘loss’ in the waste water can be recovered in a second reduction.

The third loss is simple transfer losses which could add up to .25g on this simple setup.

So to total it all up, a single pass results in very clean oil at about 50% of the potential oil volume. That’s backup up with the lab test results showing improved potency from ~33% up to ~78%.

Good news, these losses are recoverable. This means the process is a crude fractioning of the end product in it’s simplest form. This simple process has tradeoff which means the burden of cleanup is messy in the kitchen. Water makes it very easy to separate the best oil, but makes it messy to reach 100% extraction. I think of this process like onion skin layering. The first layer is easy, the others more work to recover; the 80/20 rule dominates. I am currently obsessing on optimzing this second recovery. Your question is my concern, fortunately there is an answer. I will publish how to recover these ‘losses’ in the ‘RxCE Shop Manual’.

Going back to beaker’s work, as I understand louching, its the ratio of water to alcohol + concentration of dissolved plant compounds. The plant contributes to the emulsion depending on the total bi-polar amphilics (phospholipids being one of them) dissolved into the solution. The longer the soak, the more amphilics, the greater the ‘loss’. Fortunately these emulsion-tied-up oils can be boiled out. The hard emulsion does break as the water steams out. Interesting enough, the water wont boil until this emulsion is broken. Apparently, the oils in the emulsion absorb some of the BTU’s being pumped in until the water/oil ratio shifts.

Here, let me toss this out for discussion. Using the prior process called RSO 2.0 2022, where I introduced ‘Silting’, I ran 3 tests this past January and reported the results to Graywolf. Here’s a .PDF of my email writeup and illustrations to report the yields.

I hope this answers your question?

Blog-RSO 2.0 Test Results 01.pdf (2.2 MB)