Will Summit’s Achromatizing clay work instead of Cbleah?

Have not tested it. To be clear, the magsil-pr alone following the saline scrubs will work, it’s just cheaper in the long run to load with adsorbent scrubbed material. So I would assume the product mentioned would help to accomplish that goal

It may be at scale, in fact. We have taken processes that require chromatography and scaled or automated.

No, chromatography isn’t new, but a lot of people in this space are intimidated by new procedures. I taught undergrads chromatography and let the hilarity ensue…One of the assistants (who had been working for 1 yr doing grad level organic chemistry) poured his whole workup (aq and organic phase) out of the sep funnel onto a very nicely packed column. Luckily he had the hood sash halfway down, cause shit went every where.

As for sourcing good material, hopefully the market gets there. But what about the crop that gets dust blown from “you name the crop” next door. Their oil is garbage on the legal market.

Bifenazate and no PBO? They go together like chocolate and peanut butter. Propioconazole? Can I get some ice cream with my con (azole). Jokes aside. I have remediated both of these pesticides using the above mentioned tech. Propioconazole is actually in the same class as myclobutanil, triazole. Both molecules have Log Kow’s below 4. THC is published at a Log Kow 6.97. This means that there is at least 3 orders of magnitude (1000) difference using this measure of theoretical polarity (Log Kow is an octanol/water mix, a negative Log Kow means they dissolve in water better than octanol, so the lower the Log Kow, the higher it’s theoretical polarity). I look at Log Kow cause it’s super convenient and I just use it as a qualitative number to help me decide how much effort/priority to put into the experiment.

So just follow the instructions in the SOP and you’ll be ok. The loading amount can actually be toyed with but don’t do that until you’re comfortable. I highly recommend learning how to do TLC so you can confirm when your cannabinoids are eluting (use a freshly made fast blue TLC stain). Don’t be too greedy at first (unless you want to test all your fractions off the column or out of the LLE).

TLC of Cannabinoids 2004.pdf (296.5 KB)

I just post this as an example. Don’t use any of these systems if you don’t know how to store, work with dispose of the chemicals they use.

Clear as mud?

so I have ran some dirty trim through our co2 machine and am wondering what you guys think the best method to clean the pesticide’s out of the machine any thoughts or help would be great was going to run ethanol and the do a high pressure run at like 3000psi to try and rid the system of impurity’s any help would be great thanks guys

Agreed. But chill please

Copy that

if i were to use the degumming enzyme after my carbon scrub solution has cooled, how much would i use for 1000g of crude and how long should i let it mix before filtering?

Standard dosage for the enzyme is 1-2g per kg of oil. We are also about to launch a degumming clay that requires between 1-5g per kg and can be filtered out after mixing and does not require water to activate. @AnonymousD

and my coworker once again is over here telling me im wrong lol. he told me the shit was too expensive to use every time, i assured him the amount used is very minimal but the idea got shot down anyway. now i can rub it in his face, thank you.

how much water does it take to activate the enzyme already available?

Always a pleasure to help, especially in that environment.

People like to talk about how expensive some products like MagSilPR are, but at scale you are talking about somewhere between $.09 and $.13 per gram extra cost for pesticide free oil with MagSilPR, smfh.

Degumming is a great way to improve the production process overall, so we do our best to both make the products available and cost effective for commercial production.

As for water incubation, 100ml was the amount commonly used ever since the enzyme was launched, not sure what the minimum amount that can be used is but theres a starting point.

100ml is nothing, thank you so much. going to run this by the boss today lol

I wonder if everyone is redistilling after the column. I have theorized that this is unnecessary if one uses traditional organic techniques for removing residual solvents.

On another note, has anyone done research using alumina?

I play with LLE but redistilling is the teachable way to go. Alumina is awesome for some contaminants but MSPR scales really well and is simple. However, i bet passing through alumina after degumming clay may be useful. @drjackhughes

is degumming clay something else i should be considering?

Bifenthrin is why I am here. Looking for a solution to rid this pesticide. So far no luck. So much chromatography on this stuff but still it remains. I’m wondering, do pesticides embed in THC molecules/vice versa. This was a co2 extraction by the way. Too much time and money on this matter and a lot of material to just put it to the side.

Bifenthrin remediation isn’t obvious. @AlexSiegel company can probably help you through it.

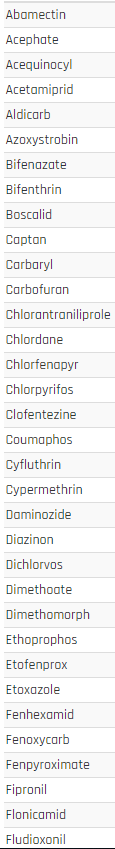

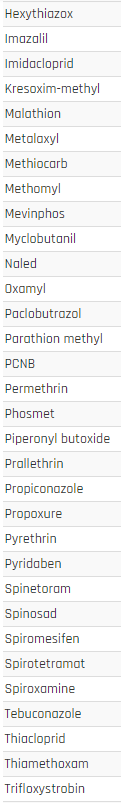

Of the suite of chemical contaminants listed in the files attached to this post, does anyone know which ones are or are not able to be removed via this process or one similar to it?

Additionally, are any contaminants able to be removed via simple SPD? I’ve been told that distillation always results in the concentration of contaminants, but AFAICT compounds that have boiling points that differ significantly enough from THC should be able to be removed via distillation.

This is the million dollar info no one will typically share. Is anyone willing to share?