Are you running t41 and silica

Or t5 and silica ?

Not sure reading your post

Lol, I didn’t even notice that.

I am using only sillica and t41 (40-50g/80g:900 bio)

yes i start with a low psi by only opening my valve a small way, but make sure its always flowing out on the scale, so still assist with N2

the biggest * of the way i do it is i put the media in a 3 inch reducer inline

so to be clear I use a 4x48 column with 3 inch reducer with my media in it.

I use it one time . the amount of media is hand tapped and lightly packed media.

sillica (top)40-50g

t41(bottom) 80g

sub zero solvent at a ratio of 8:1 (could probably use less)

start with very low psi when you are n2 flushing the column after all the solvent is in it.

you should start building a decent amount of head pressure naturally from putting 8:1 lol

but yeah. thats it. instagram @tokintotem

Pls clearify subzero. Is you material also frozen. Soak time, dewax. Ntane, isotane, blended. Lots of clarification needed.

I run silica, t41 and t5 at 35g sil 50g t41 and 50 to 100g t5 per lb. I freeze my material columns on dry ice for 3hrs or so. I typically use straight isobutane chilled to -70c to -80c. So i dont usually have much head pressure maybe 15psi max.

I run this way without a dewax or soak

subzero to me lol

tank on dry ice for a few hours, I couldnt tell you the exact temp I just know everything freezes up for the whole run after it all gets flowing.

No soak time, directly thru, (but because of the bottle neck i believe it filters thru a little slower aiding the media to be effective.)

70/30 distilled butane propane.

i keep the runs at 900g for remediation as I have had the best results with my media recipe. i although i do feel I’m wastful sometimes.

it sounds like our techniques are very similar. i dont chill down my columns tho.

i just find when i use the 4 inch plates it just wants to find the best channel. Honestly when using 4 inch plates i feel its neccesary to use more media because it takes more to create the layer compared to the 3 inch that just kinda bottle necks it all.

I havent tried a run without t5 in the mix. I been having yield issues lately. I though it was due to over exposure to the powders. 1 was hitting 10 to 15% but i havent had anything close to those numbers lately.

Ill be running inhouse stuff next week. Ill be able to have a beter comparsion to c if my changes fix stuff

I will replace the t41 for t5 on like greenhouse material that i want to be YELLOW.

t5 + sillica = good looking neon yellow

t41+sillica= clear

after reading your amount let me get this right, (35g silica) (50g t41) (50-100 t5)

i think i would eliminate t5 all together and use a little more t41 (+30-50) (if clear is your goal)

ALSO you are using your recipe per 1lb mine is per 2lb wich means you are using A WHOLE LOT MORE media then me. and that could probably be why you are losing some.

cause per your numbers if i ran my 900g run it would look like (65sillica)(100t41)(100-200t5) and that seems like just too much and is probably why you losing so much.

I reserve my right to be completely wrong lol

For anyone who was following my earlier post about making isolate on accident after rerunning some CRC product. The test results came back at 95.06% THCA for the powder found at the bottom of my material column, the terpene test isn’t back but I’ll update tomorrow when I get it. My guess is it’s under 1% terps.

One of the few extractors I know in person and am good friends with did this a couple years ago when I was there and no one knew what the fuck materialized. Some got sent off and that was the last I heard however this was our exact suspicion

I think the more material you run at a time the less medea you need, yes ratios are per lb

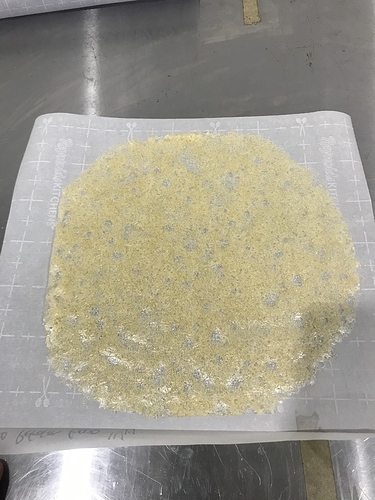

Here are my results:

First picture is control, -70 ran outdoor bho

Next is indofabs recipe

Then t41 and silica

And finally the perform 6000 with a little silica

The material I have must be dark af, cause I’m getting some yellow in the perform runs I’m doing now.

Woooooooooooooow. Great job! Love the control run to really give us an idea of what happened. How were the yields, smells, flavors, or any or info you can share.

Thanks!

Mine are yellow as well, the slab is a little misleading as it is so stable its still slightly muffined. I poured some in jars for diamonds ands it’s a nice bright yellow not orange like the t41

i would say to safely insure a clear color i like

40g/40g/450g bio in 3" reducer

sillica and t41 only check my instagram for results

Yields are all very similar, I run plenty of solvent to wash out the media. Smells are all very similar, no profile of the original material tho. Haven’t tasted them all yet

new to the crc tech alot of info on this so exciting. was wondering can you run active or do you have to run passive. also see some things about presure but not much any more on that thank you

This was runs 7 and 8 on a single CRC load. Last year’s outdoor to be distilled. This was after decarb and just shy of 1kg crude. When my medias are spent i now push 2 more columns, about 15 to 18lbs of food grade material being ran to distillate through to get the last bit of use out of my CRC before swapping. Definitely makes for a cleaner crude.