best wishes to your uncle. I happened to know Icariin during my previous job, we use enzyme to get 98% Icariin which is a more economical way comparing to extraction.

Probably the best formulation for a simplified, ‘good enough’ NE offering significantly increased bioavailability of icariin would be organic high oleic sunflower oil for the dispersed phase and glycerol for the continuous phase (oil solvent and sweetener). Without getting too technical, when using a rotor-stator for high-shear homogenization (HSH), aka high-shear mixing (HSM), the viscosities of the two phases while homogenizing are essential to achieving the smaller droplet size while maintaining turbulent mixing (rather than laminar flow). And trying to match densities at storage temp is important (for any NE method). The dispersed phase fraction (ϕ) isn’t a critical factor for minimiming droplet size with batch HSM at ϕ<0.1, and ϕ>0.1 makes attaining <200 nm droplet size with low PDI challenging when using natural emulsifiers and surfactants.

The surfactant would be saponins from type 2 quillaia extract powder boasting acidic stability, low SOR, low mol weight, quick emulsification, and emulsins with ≤-30 mV zeta potential. Possibly with a minor amount of deoiled sunflower lecithin or its derivatives as a synergistic emulsifier. The bitterness of quillaia can be an issue, but considering its low SOR when using ϕ⪅0.05, the bitterness is typically not a concern. But, the NE can be diluted into a sweetened or flavorful beverage to hide residual bitterness if it’s a problem.

I need to read up on icariin to see if an oil phase antioxidant would be helpful to prevent/reduce potential oxidative degradation. Along with its solubility and the effect of pH and temp on its stability. And which other bioavailability boosters would make sense, are easily sourced, and not contraindicated to his medications (relying on his doctors’ input for interaction concerns).

All of those ingredients are fairly inexpensive and easily sourced.

I should have time starting early next week to read relevant research and finalize a basic formulation and SOP. It shouldn’t take much time considering the goal isn’t perfection or even an ideal formulation; instead, a product with increased bioavailability can be made ASAP.

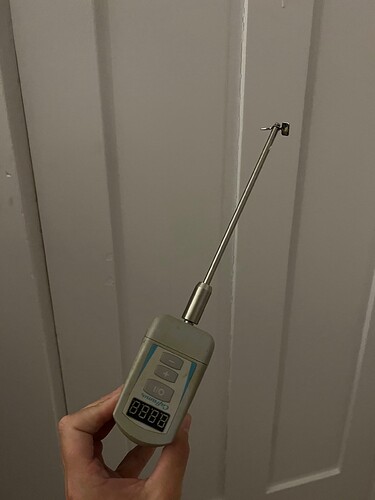

I assume you have the viscous stator, which isn’t ideal for making an NE. But it’s better than nothing, so it is absolutely worth using if we don’t have access to a fine stator, ultrasonic, or a high-pressure system. Do you have anoverhead mixer?

You’re welcome. My pleasure.

I don’t. But I know of a few university analytical labs that are reasonably priced and could analyze purity. One uni lab I use runs $400+ for purity analysis. In contrast, private analytical labs like Intertek or Eurofins can charge thousands.

Maybe @kcalabs would be interested in testing the purity of icariin and checking for heavy metals, etc. They seem like great folks, and they are incredibly skilled.

I should have HPLC test method in my computer, will list here if I find it

That would be wonderful. Would you happen to know any reliable suppliers of 98% icariin?

i will check with my former colleague if they have 98+% in stock,I will try to get some free sample if they have

pffff just heard that a 3 th relative has passed from pancreatic cancer

grandfather , best friend of my wife and today the wife of my nephew

last 2 where mothers of young children and it sucks

so as a result of my r and d on acidic cannabinoids I have in stock hundreds of liters of

unwinterised crude almost void of cannabinoids (4%) and probably rich in

fats and waxes ,terpenes , BUT flavonoids as well and I wish to isolate these from this gunk crude

the biomass was all extracted with petroleum ether 40-60 C room temp

what would you guy s recommend as the next step ?

winterize the lot to get the fats and waxes out then LLE the lot ?

since this is all so fresh I am completely lost about flavonoids don t know much of this molecular family but I might as well give it a shot in extracting them since I have probably all that’s needed to get them

and honestly I feel I have mastered most cannabinoids

extracting or isomerizing and that there is not much in the cannabinoid field that interests

me so I welcome a new challenge

Determination of Total Flavonoid Content (TFC)

The TFC was measured following a spectrophotometric method by Dewanto et al. (2002). Briefly, extract of each plant material (1 ml containing 100 μg/ml) were diluted with water (4 ml) in a 10 ml volumetric flask. Initially, 5% NaN02 solution (0.3 ml) was added to each volumetric flask at 5 min, 10%

AlCl3 (0.3 ml) was added and at 6 min. 1M NaOH (2 ml) was added. Water (2.4 ml) was then added to the reaction flask and mixed well. Absorbance of the reaction mixture was read at 510 nm. Total Flavonoid Content was determined as quercetin equivalents (g/100g of dry weight). Triplicate reading were taken for each sample and the result ave

It may be possible to use this as a “guide” that lays out a complex playing field.

Extraction of Flavonoids From Natural Sources Using Modern Techniques

doi: 10.3389/fchem.2020.507887

An interesting discussion with water alcohol systems…

Enlightened views which also apply to cannabinoid…

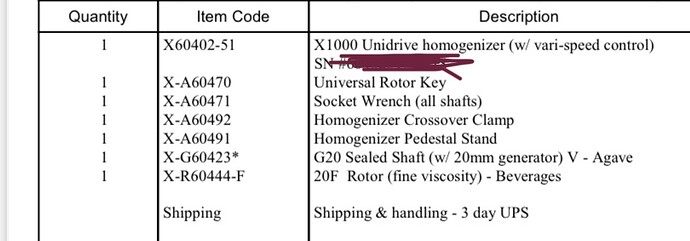

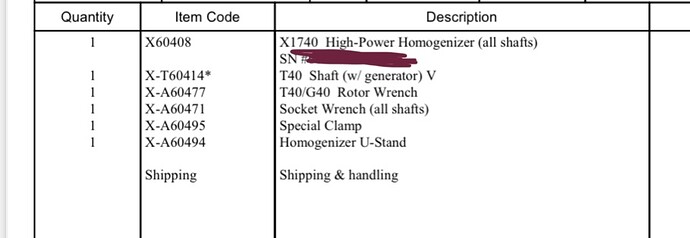

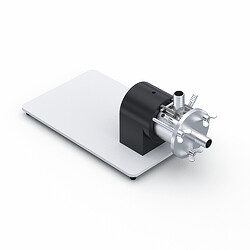

I heard back from Daniel. The X 1000D, G20 shaft and V and F generators are in stock. He can ship them on Tuesday (Monday is the Unity Day holiday in Germany). I’m not sure about the X 1000 or X 1740.

Wow, that’s great you have the fine generator and the X 1000! You can make NEs with that. ![]()

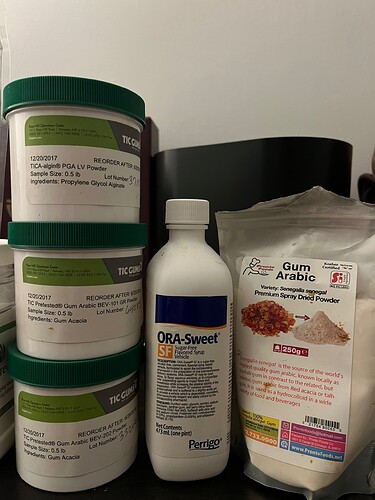

Regarding your ingredients, compared to natural, low mol weight surfactants or emulsifiers (e.g., saponins and lecithins, respectively), modified starch (MS) and gum Arabic (GA) are not optimal choices as NE emulsifiers when using HSM. Because, for example, they have low surface activity, less negative zeta potential, and slower adsorption. When using HSM for O/W NEs, MS is better than GA because it has faster adsorption, greater increase of continuous phase viscosity, and can more easily form smaller particle (droplet) sizes. When using HSM without an optimized formulation and/or longer homogenization duration, GA’s slower adsorption leads to greater drop-drop coalescence than MS, meaning greater particle size.

With HSM, I consider MS and GA mainly to be viscosity modifiers and emulsion stabilizers, even though they act as emulsifiers. They are better suited for batch ultrasonic processing or multi-pass high-pressure methods when used as emulsifiers.

Cyclodextrins (CDs) and their derivatives are useful for emulsification by forming inclusion complexes to increase water solubility, and they function as emulsion stabilizers.

I tend to shy away from MS and CDs for clean label formulations.

Type 2 quillaia extract (60-70% saponin) and lecithin are fairly inexpensive and would be better choices when making NEs using HSM. Although, also including MS in O/W NEs helps increase continuous phase viscosity (which is essential with HSM).

Good Morning from across the pond

The link does n t open please check

As for solutions I have several polymeric beads with moderate polarity and advertised as flavonoid catching which I am gona try asp

So sop so far is

Winterise the gunk

Dissolve is a alkane

Pass over beads

Wash beads with ethanol/water

And send of to a lab specialised in flavonoids in Germany

Update!

Uncle wants to move forward. I’m going to speak with him in the next couple days to discuss getting a line of communication open with his doctors. @Ralf @anon56994712 @QBD420

Everyone should be made aware, CAT’S main manufacturing focus is on their micro jet turbine engines. The lab equipment side of the business is nothing more than a aggravation to them, and their distributors suffer because of it.

Is there a company out there with similar products that’s focus is homogenizers?

Nope, not one!

As far as I am aware, the isolation of flavins & flavones will require chromatography. Certainly, the test you posted, @Roguelab , should be able to quantify them, but only destructively, and only after they have been separated from other things that may react in such a test, such as the cannabinoids and some terpenes.

I am very sorry to hear of these health problems with your loved ones, @Roguelab . I’m sure you can help them in some ways, of course. Take care, my friend.

I agree that isolation of these compounds is a

New challenge and that chroma is deffenatly the best method

At the same time working with crude has thought me there are many ways to skin a cat

And thinking outside of the box might give options

Polymeric charged beads are an amazing

Tool and as it seems some are advertised as flavonoid extractors giving me hope for different paths and techniques

Think that RO might be a tool as well since there size is quiet large

Well see where this rabbit hole takes me to

Is there a company out there with similar products that’s focus is homogenizers?

Yes, many companies. An inline high-shear homogenizer may be worth checking out if you’re looking for something to replace the DK30.

Check out IKA, for example; they have a range of high-shear emulsifying machines; although finding used equipment may save you significant $$$.

Also, have you asked Daniel about the lead time for the DK40? The DK40 converts the X 1740 into an inline rotor-stator. It’s jacketed for temp control, although I tend to find using a jacketed process fluid tank better controls temp.

And on the topic of process liquid tanks, adding an in-vessel mixier is always a good idea (e.g., triclamp top mounted sanitary mixer or triclamp bottom mounted mixers like the MBE-12D or the magnetically coupled mixer from ISM; but I’m sure Alibaba would yield better prices).

Check out the posts by @raghanded:

There’s a bunch of ways to do it depending on your process. Look into inline homogenizer setups and / or find a silverson or similar batch homogenizer. Still working on getting a lift fabricated for my 800lb 25hp silverson homogenizer that I’ll be using for topicals: [IMG_20220818_120434279] [IMG_20220818_120442333] … but I’m using this smaller greerco batch homogenizer and an inline IKA dispax reactor for cosmetic bases currently. [IMG_20220818_115705999] [IMG_20220818_115726168] There…