Hey guys! Have a ETS MeP 30 setup with corken t91, - a couple of MTAs, Huber 825 & a Huber cc902 heat circ bath. Trying to figure out how I could maximize output / upgrade the system, need to knock out as much dry bio as possible in a 8 hr shift. I’m very certain many of you have some amazing input! Thanks!

If you can get someone to come in 2 hours before or after the 8 hour shift to make sure all your sintered disks/filters are clean and to make sure you operating tank is full of solvent, that will set up your extractor to just run for the full 8 hours, and not have to deal with cleaning/changing filters or distilling gas. it helps a lot.

using straight propane will increase recovery speeds

skipping CRC, obviously (if you even use it)

How important is crc to make hydrocarbon crude ?

How important is low temp?

Why dont you start with telling us what your current throughput is at and what your goal is.

Knowing that can determine if you may be missing something simple or if you need to consider a larger upgrade.

but maximizing operating time is a great first step as @ZizzleB said.

But you could also just need a deep cleaning and have restricted lines somewhere.

The easiest way to increase throughput is to increase recovery speed and increase the amount of biomass per column . Maybe try grinding your biomass more fine to get more per sock / column . Increase pressure throughout the whole system to acheive higher flow rates . These are a few things that may help you increase your throughput. Higher pressure equals more flow through the system.

As long as you feel comfortable doing this and your system is pressure tested your fine . For example instead of injecting columns at 40psi fill them at 80 psi and they will fill twice as fast. Let your recovery pressure build to 60 psi then start recovery and try to maintain a higher pressure this will help you acheive higher recovery speeds .

Yep, these are also great tips. ^^

even 1 extra pound per column will go a long way if you are doing 50 runs a week.

It puts more cannabis in the tube…

Have you tried beating it with a stick?

kind of a subjective question. I think crc is important because it makes for cleaner, better looking distillate. some people don’t care about that and just want throughput.

just depends on your downstream processes and what end product you are trying to achieve.

We plan on using crc and yes cold temp

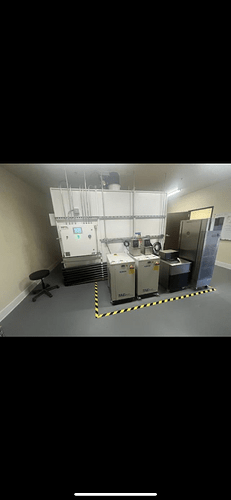

So as of right now the facility is idle, but it’s turn key I could take it over but idk if it’s ideal because of how small the output is, I just don’t want to set my self up for failure, I ideally I would like to run at least 300 dry bio in 8 hours, but I know that could be a stretch as these stock mep30 colums barley hold anything & there’s only 3 colums. I’d like to make sugars and thca isolate / diamonds

Ive heard about the xt70 upgrades etc

Going to need a whole lot more than a few upgrades to hit those numbers.

manufacturers numbers are usually vastly over promised but if it did even come close you are only at 120lbs in 8 hours. How competent are you at running a closed loop? A fresh operator isnt going to get close to those numbers without knowing the system like the back of his hand.

The MeP 30 offers more material throughput than any other extractor its size. The MeP has a capacity of 10-30 liters with the ability to process well over 15 LBS of source material per hour.

Like @thesk8nmidget said, you are gonna need more than a MEP30 to extract 300lbs dry in 8 hours. a lot more. those columns on the MEP30 only hold like 5lbs dry.

gonna need more than the XT70 too honestly… a MEP30 AND an XT70 together might be able to hit 300lbs in 8 hours.

It puts more coconut oil on the gaskets…

Elliot from ETS here.

First thing that comes to mind is our new bag filters. These can replace your sintered discs and will require less downtime cleaning filters.

Second is using nitrogen to assist the movement of gas through the extraction columns. IDK if you are using that currently but will speed things up. We can also reroute the corken to the columns to help create a greater pressure differential when filling with solvent.

Also I would look at your heaters, cold systems need bigger heaters to recover the solvent at a normal rate. We use to sell smaller heaters for the cold 30 systems but that has changes in the last few years. I would recommend 2 - 315b Huber heater for the collector and 1 - KISS 202 for the expansion columns.

Simple, increase your heating and cooling KWs and add our butane falling film to it and ditch that compressor. You’ll be crushing 1000 lbs. bio a shift

Can’t see from the pics but a small condenser on the outlet side of corken seems to speed things up abit by shaving some temps off the vapor before it hits your main recovery condenser.

Can you elaborate a bit more on these bags? I’m very curious! If we can avoid discs as much as possible I’m interested!

they look pretty legit. it’s another small column that would go right after your material columns. you ditch the sintered disks in the material column, then the mycella goes from the the material column into this “filtration column,” which houses the filter bag of whatever micron you choose… and yeah the bag acts as the sintered disk essentially, just much more surface area, so less clogging.