Im about to start my first every run on my 2L SPD system, my goal is to make some THC Disty but I don’t want to use my crude oil on the first run so I got a gallon of virgin coconut oil from Costco and I would like to fraction the MCTs from it, after a lot of digging I found the 2 attached PDF papers, one focuses on fractioning MCGs via short path using a lipase catalyzed reaction, and the other one is about fractionation of coconut oil via supercritical extraction, I thought they were pretty interesting so I thought I would share them but its not really what im looking for.

If anyone could point me to a paper or some info about how to fraction the MCTs from virgin/refined coconut oil would be amazing, or just the basic parameters on how many fractions coconut oil has and at what temps each one is separated.

Cheers

MCG-S.pdf (104.3 KB) 5 - IFRJ171029.R1-Final.pdf (370.5 KB)

1 Like

Check this paper out, I’m still reading through it, but it appears to be best information that’s easily accessible.

138901-3636-IJBAS-IJENS.pdf, Fatty Acid distillation.pdf (scientificspectator.com)

That second paper I linked has actual boiling points for the fractions listed in the paper

1 Like

Are Medium Chain Fatty Acids the same as MCTs ? Im down to using the parameters of the first paper  that’s exactly what I was looking for thanks man.

that’s exactly what I was looking for thanks man.

2 Likes

Here’s an article that will give an idea between triglycerides, and fatty acids. I’m still reviewing it, but here it is if you want to check it out: Difference Between Fatty Acids and Triglycerides | Compare the Difference Between Similar Terms

"What is the difference between Fatty Acids and Triglycerides?

• Fatty acids are carboxylic acids with -COOH parts, whereas triglycerides are organic esters.

• Fatty acids are derived from triglycerides.

• Three fatty acid molecules and one glycerol molecule undergo esterification to form one triglyceride molecule.

• Unlike the triglycerides, fatty acids can be divided into two categories depending on the presence of C=C double bonds. However, both these types are involved to form triglyceride molecules."

1 Like

This actually seems like a cool project! Kudos to you for wanting to give it a go!

I can say I’ve learned alot this morning that I didn’t know before

1 Like

Food for the brain huh !! Ive been learning non stop the past few days lol.

Ill post my results after I give this a go, thanks for the help cap!

2 Likes

No doubt! Happy to help when I can, and I’m a triple black belt when it comes to my Google-Foo. I do nothing accept learn at this place! I get lost in some of threads, and they turn into a black hole of information.

1 Like

Good Sunday to you @Capttripppp !

Im about to get started on this coconut oil fractioning and I was wondering what temp I should use at the condenser, it does not say anything about it on the paper you shared with me neither does it say on the ones I got so im really not sure, what would you recommend ?

Im going to try this 3 fractions

1- <140 C

2- 140-170 C

3- 170< C

1 Like

Here’s 1 paper on distillation of long chain fatty acids. I’m right in the middle of reviewing it, so I’m not sure if it has condenser temps yet

InTech-Distillation_of_natural_fatty_acids_and_their_chemical_derivatives.pdf (831.5 KB)

1 Like

Those temps look good, but you might want to go a little lower. If you read the paper I posted, it has alot of temps in there, but all of them are distillation temps and not condenser temps. You should be able to keep your BPs low because you’re using vacuum. I don’t think you should have to go over 250C to distill everything. That paper I posted has tons of good info in it!

1 Like

Rule of thumb is a minimum of 20⁰C lower than your vaporization temp. I would try something more in the 40⁰ to 50⁰ range. Too cold and it will clog up.

3 Likes

im about to start, thanks for those papers, lets see how it goes

Will try this temps, its the same Id like to be able to achieve and maintain during THC distillation and since that’s what my goal is it’ll be perfect for practice, thanks.

If you can fractionate the oil then you will have gotten the basics down. Get it tight so you can pull a good vacuum and control it. Make sure your cold trap is sub -80 or you will blow through pump seals when you are extracting cannabis due to the residual etho in the crude after winterization. SPDs are a blend of art and science, it’s about as hands on as you can get. Running a wiped film or band is easy in comparison.

2 Likes

thanks for the input my friend, will do, im about to start with 500 grams of raw virgin oil, lets see what happens

I had to put some teflon tape over the KF25 PTFE fittings, they are located after the valve on the monocow, is this good practice ?

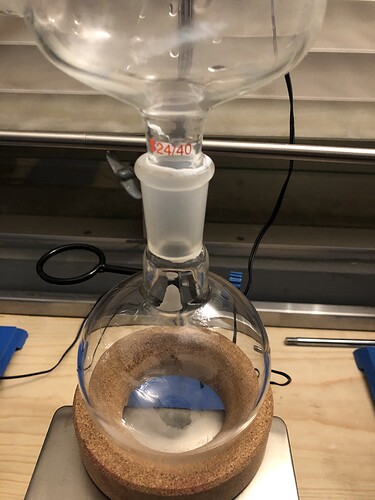

Heres a pic of what’s going on right now, I set the condenser at 45 C and right now the mantle is hitting 125C, nothing is happening yet, I hope I start seeing something by 140C

1 Like

First drop to come out of the head unto the receiving flask was at 280C

I slowly went up to 300C and it started flowing gently

Right now I got it at 310C and its coming out pretty good, I’ve changed receiving and in the process ive lost vacuum, did I create a leak or why does this happen ?

Im stopping the process cause I can’t get the same vacuum I was able to get at the beginning

As I write this it came down a little to 190 microns, could it be that I cant get vacuum like in the beginning cause some gasses went into the pump ?

Another thing that seems weird to me is that I got absolutely nothing at any of the 2 cold traps

1 Like

![]()