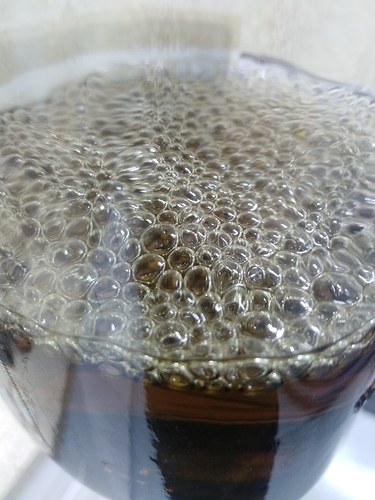

Anyone know how to avoid this? Can I avoid this if I heat distillate to a certain temperature before pulling vac?

Whaaattt?? How much vacuum are you pulling and are you sure it’s disty? Looks like solvent to me.

I pull down to ~9 torr. Definitely not solvent, below detection limit for everything.

If you pull and break vacuum, then pull down again does it bubble twice? If nothing is boiling it’d have to be trapped gas

I’ll give that a shot next time. When I heat and pour distillate I always get bubbles. So I figured it was trapped air. Is this not normal? Also, when I first sealed the jar in original pic those bubbles were dispersed thru out. Over time, a few days, they migrated to the surface.

Here’s a pic of the same distillate after opening the jar and pouring some out using heat.

Sounds like a pretty plausible cause to me. No way to fix that other than heat it up and pull some vacuum to suck on the jar. I guess a centrifuge might speed it up but we’re getting eccentric there lol

How hot should it be heated? ~60C?

First of all.

When doing a transfer use argon or nitrogen flooding in the flask. The bubbles don’t really persist since both gases don’t like to be trapped.

Perform only hot pours.

Immediate capping.

Then pull vacuum.

Just enough to get it to flow. No point heating it up in the presence of air just to vacuum the jar down to get the air out

Well, that’s how I do it. I’ll heat up the flask or jar, pour distillate into new jar, and then vac seal immediately. Still end up with bubbles.

Do you mean, pour distillate into jar, and then flood flask with inert gas, cap, then pull vac. What’s the best way to do that with a mason jar - flood with inert gas? For flasks or anything with a joint, it makes sense to me as you could use a stopper with a stopcock. But I’m having trouble visualizing how you’d do that with a mason jar.

No. The inert gas should be flooding the beaker or whatnot prior to pour. Jar, beaker, flask. All the same. Always flood if you are going to store or transfer under heat

when lost wax investment casting they have this same problem.

the solution is a vibration table which is banged while the vac is being drawn.

even with any kind of gas put into the solution you will get bubbles they will just be inert bubbles.

I’m going to have to say the opposite of this.

Pour as cold as you can while having a steady flow. Unless your stuff has solvent in it you shouldn’t have bubbles like that.

It behaves normally otherwise. Very hard and solid at room temp. Can flip jar over and it doesn’t move for a long time. Tests came back BDL for ethanol (only solvent used).

if its solid then when you vac it you will not get all of the air out.

the bubbles may not be there but the oxygen will still be trapped in the distillate.

maybe if that is the case warm to make it liquid then degas it

let the distillate cool under the argon and turn off the gas when cool.

then freeze it down so its very very solid.

then vac it.

I usually pour at 70 to 75c and let the jars set in the oven for about 30 min to let gasses surface and havnt had any issues . At this temp it will vac seal itself.

You could always try using a vibrator to agitate the hot distillate so that as its setteling the bubbles move to the top? The only other thing I could think of is sonication. Sonication is good at removing odd smells from distillate, which is basically trapped terps or other gasses. I dont believe you have solvent trapped in there just terps that simulatenously distilled with your cannabinoinds.

Uhm no…cold pours force bubbles to happen and trap inside. Warm pours with inert gas will push all bubbles out. Think about it for a second.

The resin contain micro bubbles of air. You need to first thourously degas it by applying vaccum for extended time on a melted material, until bubbles stop forming. Then you can cool it down and close it. If you transfer it by pouring after degasing, new bubble will be trapped. The stuff on the picture, you could just warm the surface to make those bubble desappear.

If you want to upscale this, following degassing of you batch, you should employ vaccuum injection…