I’m upgrading from a 2LB system to a 5LB system running passive and I wasn’t sure how many watts of heating I’ll need. Does anyone know roughly how many watts of heating will be necessary to run as efficiently as possible? I’m running a single 1000W water heater and after dumping butane to my collection pot it takes about 3-5 minutes until I really hear it going in my tank

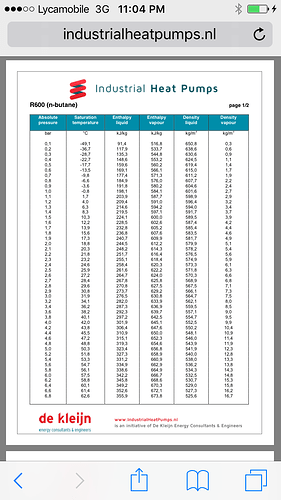

Saturation temp is boiling point

1bar is atmospheric pressure

You can now calluculate the Watt s you need

But the hard part is calculating your heat transfer to the inside of the pot

You’ll need about 3kw of heating power for each lb of butane you want to recover, per minutes. Want to hit 3lb a min. you’ll need 9kw of heating

Also that much energy is needed to recover at that rate, too

Those are solid numbers to look at. Thanks dred

Thanks for the response dred! I’m running 1/4NPT lines do you think 1LB a min is achievable if I have sufficient heating/cooling?

No. Not even close.

You’re going to need a ⅜ or ½ line, at least

What’s the maximum flow rate I can expect with 1/4NPT lines? rn I’m doing 1LB of butane every 5 minutes is this the absolute max?

What are you using to keep your solvent tank cold, also what temperature are you keeping your collection at?

Are u running jacketed collection and tank?

If not these really really really helped my speeds

Lifting the solvent tank off the bottom of the cooler(. If it’s not jacketed)

Acetone + dry ice , I’m keeping it at 90F

A lb every 5 min is great for those tiny lines

Get your solvent tank colder to pull harder is only thing you can do other than getting bigger gear.(and if your solvent tank is empty before recovering, bleed it dry and pull vac on it before running)

BTW when I hit 25-30min for 6lbs solvent I thought I was doing something for these tiny 1/4"lines. And if ur tank is setting on the bottom the cooler there’s another spot.

I have my collection pot and solvent tank setting on one those trays during recovery(this took me from 45min to 25-30min)

Hmm there s a little research project

your solvent tank colder to pull harder is only thing you can do other than

Anybody ever set a micron vacuum gauge to a collection pot at difrent temps ?

Wonder how much cold / vacuum once we go below -40C

Hear me out

We pull a vac on our system before we start but most do this with a singel stage /diafragm / etc vacuum pump

Shut the pump the vac inside the cls is almost the deepest vac level inside that system cooling the system after the vac has been pulled might lower this number a bit

But I wonder say we pull a 1 micron vac on the cls then proceed as usual would the process not work a lot beter

(Deeper vac harder suck ) at maybe even higher temperatures

@downtheterphole @Dred_pirate @Krative.

Since most work with dry ice has anybody ever calculated the optimal vacuum depth for say -80C cooled system

It s an easy factor to manipulate

And I would not be surprised that we are not using the dry ice temp at it s best for we do not pull enough vacuum on the cls

Always begin with the deepest possible vacuum in your system, for sure. But are you suggesting pulling vacuum on recovery tank while passively recovering? I suppose you could but you’d need to use a recovery pump and pump the vapors into another recovery tank. That’d actually work really well, especially if you had a condenser placed before your recovery pump suction port

Pressure is direct correlated to boiling point

We use a fairly fixed temp working with dry ice (passive)

But I wonder how many use the corresponding vacuum depth for optimal running

I’m not sure I understand what you’re asking. Do I measure the vacuum with while I’m running? Yes. It’s how I determine whether I’ve gotten sufficient cooling power

Ok

If we pull a vac on our system before injecting this is the lowest vac the system will see right

Now say the vac you pulled is 75000 microns the bp of butane is around -50 C

But we are cooling with dry ice -78C

We basicly are leaving to wast 28 degrees C to speed up the process

Boiling and condensing of compounds are fixed amounts of energy only time to give that energy is not

If I pull the vac at wich the bp of butane is -77C I will have the highest suck on the line ( pressure differential )

Speeding up my process right ?

Look @Dred_pirate uses a Venturi to pull a vac 25 hg his vaclevel can not go lower than this once the system is injected meaning as of that moment the boiling/condensing temp is fixed

But the pressure differential could have been better speeding up his procces

I realize there are many factors that come into play but isn t this one factor

That we are able to calculate the optimal vac pressure for ?

it’s easier to condense without the vacuum.

adding heat is way easier than removing it.