-60c, preferably.

Cool thing about -40 is that it’s -40c and -40f… well maybe more like really cold, not cool. Lol, idk, stuck on dad joke mode.

I’ve had pretty decent results at -20c in etoh and butane, but prefer colder for butane. Still pulls more fats and waxes than I’d like with -20c in butane. Since most of my eho winds up being eaten in edibles, -20 is about perfect, but again, I’d go colder for smokeable.

I’m sorry, I’m not asking about the tempeture but about a most efficient lenght and wide of a material column…

I was just shooting from the hip!

And will tell you that

That’s pretty specific for a spoon…

Have your tried the search bar?

Yes, for a example Graywolf says 4x36"

For how long?

Would you like the link again?

I was responding to someone else’s response.

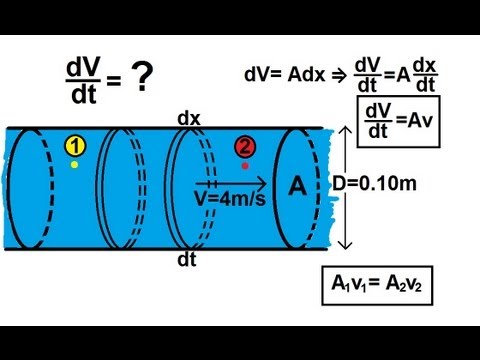

But, while I’m at it. Fluid dynamics are a thing. That tiny ⅜" line doesn’t really allow fluid to effectively, or efficiently flow through a wide open column. Especially one that short.

And that vacuum jacket on the ets material column won’t do shit for you. Your solvent will still warm up. I would have a a chiller keeping it, and the solvent tank the same temperature.

Word of the day

4" columns work far better than a 6".

So maybe just cool a regular column at the dry ice bed before a run…

Also I run 1/2" lines on everything and those wider Swagelok valves SS-44TS6.

I’m now using 3x36", but need a little bigger one where I can fit 3-3.5lbs.

If you already have vac on the column, hook it up and run, that’d work. But I wouldn’t let it sit and warm up. And yeah ½"does do better, especially on that small of a column.

So bigger, IS better?

I just run it fast and cold(tank in dry ice slurry, no coil)… Vaccumed column in -45°C freezer over night, 3-5min to connect and go…

Hi @Skaman ! My recommendation for that specific size is based on the industry standard diameter (6"), but I give a maximum length based on empirical data accrued through personal experience and trusted anecdotes over the past decade. It applies only to actively chilled columns, which should only be used on fresh frozen biomass. IF you use active cooling (i.e., circulated coolant fluid, static dry ice bath, or other chilling material in the jacket around the column) on columns of dried biomass, then my recommendation DOES apply.

The length recommended in that post has nothing to do with insulation like bubble wrap, blankets or vacuum jacketing. However, any insulated columns of biomass should be limited to four (4) feet (48 inches) in length. This is already standard in the industry.

The truth is this: The use of a tall cylindrical form factor to contain Cannabis during extraction with butane/propane is really just a holdover from the bygone days of open blasting. It serves no genuine purpose, and it has probably only persisted due to the regulated operating pressure limits of the standard sanitary tube dimensions. It is the popularity of the “triclamp” mode of tube coupling that forces us to confine our BHO extractions to a maximum 6-inch diameter flange opening.

I disagree, I think columns can make better product with a little finesse

Better than a vessel with a different aspect ratio… like a belly tank, for example? I’ve used both, and the product quality seemed essentially the same. However, it is faster trying to evaporate leftover solvent from a short & wide aspect ratio vessel than from a tall & thin column. That is the main benefit of which I speak… although a short & wide vessel also allows for solvent residence time closer to equal across the entire block of biomass, as well. Naturally, anyone is free to disagree with me, but I want to make sure you understand I am only stating physical facts, not my opinion.

I can make a more refined product in a column as opposed to a vessel like a purge labs tank

I’ve run fresh frozen passive with precooling my gas tank in a -40 freezer and my plant material at -80 with no jackets on the material column. Just smash and blast (no presoak) and got good results.

I’d recommend -40 as your operational target and -30 being acceptable in case shit happens.