Lol you think the dents will pop out…

If anyone can give me any reason not to use these let me know 8==D~~~~:heart:![]() ¡

¡

Structural integrity, its a cheap thing to avoid if there is a problem.

Still not seeing how a few tiny dents would affect its overall structural integrity. I can see if there was a very large dent how that could be different…

Wheres psychopath when you need him…

It might not, its just now your weakest point. I was a high pressure pipe welder starting when i was 18 and i still have 100s of welds with my stamp number on them and we wouldnt and couldnt use any damaged or dented pipes. I prefer to error on the side of caution when it comes to things with a small margin of error and devastating and expensive consequences

I more like the idea of daisy chaining columns; it just becomes a pressure issue, which in turn becomes a retention time issue (assuming you’re speaking of chromatography to do this).

I’d look at utilizing stainless steel columns (to account for pressure) and using some sort of peristaltic pump to pump material into several columns at the same time; i.e. you have your distillate/MeOH for all 4 columns homogenizing on a plate, and you pump this into your injection lines, which you would have to split (1 → 4) to connect or daisy chain the columns. So you get 4x the input material, and as long as the flow rate and pressure remains constant in the columns, the one chromatograph should be indicative of the fractions for the other columns.

Just have to make sure you have a pump that will keep up with your flow rate for your system for all columns, and make sure you don’t overpressurize when introducing the material (might have to optimize your organic solvent: distillate ratio)

I can walk thru this in more detail--chempistry@gmail.com if you wanna reach out

Structural failures ALWAYS happen at a place of “imperfection” on equipment. Typically these imperfections aren’t visible to the naked eye.

In your case, these dents represent an “imperfection” that is several orders of magnitude worse than a non-visible imperfection.

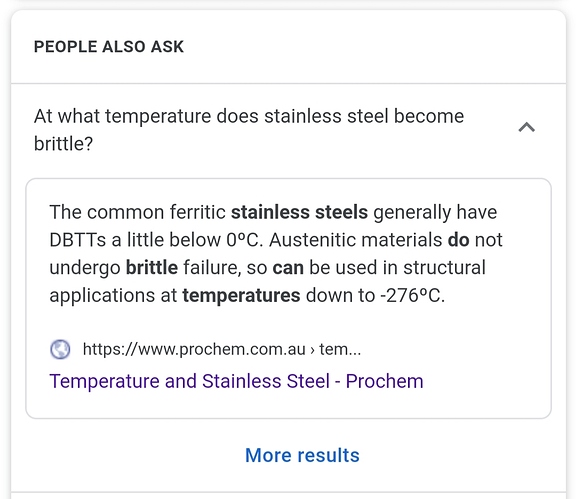

Any process engineer here would be hesitant to put any pressure in that vessel, especially if you’re running cold temperatures—the material properties of stainless lead to its brittleness at super cold temperature and a dent like that is (with 100% certainty) a weak point where brittle fracture is thousands of times more likely to occur.

If you run this equipment all day, you’re thousands of times more likely to experience a fracture of your vessel than if the vessel was still smooth

This is the answer i was looking for. Thank you.

Still useful for packing socks

So i guess its fine…

What say you?

Clearly your going to run it regardless of what everyone is telling you, so why even ask.

The answer is dont run it.

" austenitic materials do not undergo brittle failure"

no im just going off of whats actuality. if it doesnt undergo brittle failure how would it become brittle to fracture? lolz…

You are your own man.

Run it boss

im just saying…amiright or amiwrong

I guess it boils down to are you willing to risk everything for a dent. If the columns were free then who cares. Just use the good ones and use the dented ones for packing socks. Go ask the fire marshall if that would pass inspection.

The thickness of the material is critical. When you sent something, you not only reduce the overall thickness of that area, you alter the chemical structure that provides the strength of the steel to begin with.

304 stainless is not typically prone to brittle failure, but in this case it is. Especially at subzero temperatures.

Save the money, get new spools

I say you run it, no gut no glory. What’s the worst that can happen? ![]() (in italics)

(in italics)