Allow me to introduce Heptane barrel tek:

Basically a ghetto version of how they do large scale hexane edible oil extraction. Use a mag drive centrifugal pump with appropriate atex motor to pp from the sump in the bottom to a spray ball in the lid. Pump through a BPHE hooked to a small chiller to keep the solvent cooled so it doesn’t boil off.

Connect a large Graham condenser or dephlegmator in the lid to a flex line connected directly to your explosion proof exhaust system (this will negatively pressurize your barrel keeping the vapor from leaking out).

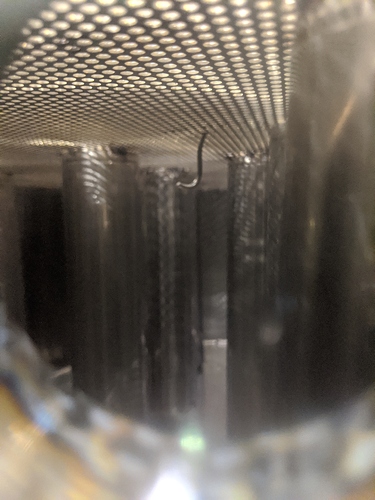

Mill your material and use undyed cotton cloth above the sump screen to hold it. You can easily fit 40kg of fresh frozen in a go.

Lastly, make a press to squeeze the lion’s share of the solvent using the same vent system. Obviously only do this while the solvent is cold.

3 washes of about 50l of solvent for 1 hour each pulls just about everything. Then LLE into methanol for room temp winterization.

There’s a ton of common sense stuff with this method (like ground the shit out of everything) but that’s the rough method. This is not how we’re currently processing but considering switching over.