They say that thang can roll over 750 joints per hour while ya kick back and medicate! Video below!

https://information.greenbroz.com/webinarondemand?submissionGuid=ebadb8d4-0c1d-4f70-9054-7fda75dd6c86

what a cool looking machine… .5g joints are a bit small. But i like the rolling technology rather the top pack action! shit looks awesome. i bet raw would make you a paper roll if you were doing enough business…

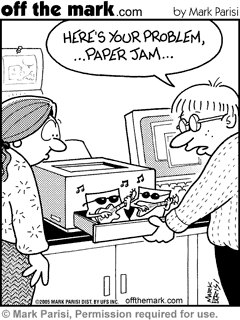

I would love to see this thing operate for a few hours continuously. That’s a lot of moving parts and a lot of (should be) sticky stuff. I foresee jams and downtime.

The motion looks slightly like a rolling box?

There are 3.5g packs of a 1/4g each starting to take off. Dog walking length I guess.

I saw this video. I thought it looked cool - but I don’t like the idea of the ends being open. Then I’d have to completely redo all the packaging, because the weed would fall out or shake out during transport, etc.

Probably they have an answer for this.

It also means having to go with completely different materials and sourcing those. Sourcing materials for pre-rolls continues to be a pain in my butt. ![]()

And it only does like half the pre-rolls per hour that some of the other technologies do. But maybe a better preroll?

Anyone using these? I wonder if they are doing in-house tests to let you see how the pre-rolls smoke. I know some of the gravity shake methods get things too packed in and lead to poor lighting / smoke quality…

I tried to set up a demo to see this machine work but was ghosted by the couple guys in US I saw listing it. I get worried about it shaking around in transport as well, prefer the twisted ends. They all look like they can get to be a headache though.

That’s a long ROI @$225k

There’s a way to put that twisting mechanism in a handheld form for pretty cheap, the name’s escaping me though. Easily the biggest pain with preroll production in my opinion.

That’s where the carpal tunnel type hand problems come in. Big hands don’t do well with that many repetitions pinching together. Let me know if you recall ![]()

Agreed. That’s why I had my team go to the “three fold” method. Instead of pinch and twist, they use the same tamping/tapping tool to smoothly fold the cone in and down. Seemed to make them faster and definitely helped with making everything more uniform, since some people would twist harder or softer, which led to us having to trim/clip the ends to keep them even. Still not sure why the bosses were worried so much about that, but they were. ![]()

There’s a couple of gravity fed machines that have auto-twisting in them. Sometimes the twist looks terrible. I haven’t found a handheld version, but I have tried one of these. It “worked” but I did not like it. You can go too hard and rip things - plus its not easy to get it to grab the end.

So again - I went with the fold. ![]() it worked so much better and way less ergo issues.

it worked so much better and way less ergo issues.

Interesting. You’re giving me some ideas!

once we are cranking prerolls… ive been looking into this beast… but the price tag is epic.

currently using the futurola knock box X 2, but i am not a fan of the vibrate tech… think a triple tamp with a poker is a better way to fill a cone.

Ragheaded that’s tight I like that, thanks for your contribution and making us aware of it. I had never even heard of that Halfestus Cone Rolling Robot before wasn’t aware it existed! I imagine ROI would be a lot faster with that than the Blackbird Rolling Center!

Neat!

We are selling this machine in the USA for $110k. Delivered…

Please look at my website: https://threewizemen.com/product/preroll-machine/

We can make .5g to 2g pre-roll and make 1500 pcs. and hour.

Setup and Training $500 a day plus travel.

msg me for details: info@threewizemen.com

We have a rollpros on the way, the sample hemp dubies smoked better than most my homies hand rolls, if its as good as the samples, I’ll let yall know

How did it workout?

Honestly, it started out a bit rough, that is why I havent posted anything about it… but that company came through clutch on customer service. Flew a guy who specializes in automation robotics, and he got our guy confident in how to maintain and operate the equipment… its a very intricate robot, it doesnt need alot, but it needs to be ran pretty often to keep the pnuematics lubed and properly functional, now that it does run, it runs pretty consistently, and the issues are now something the guy who runs it understands and can sort out…

So many moving parts, its an upgrade from most of the other options, it rolls the joints different than anything else, and for that it does a really good job and the output is about 700-1000 per hour with 1 man.

How is it still working for you all?

We’ve had one for over a year and it’s been a nightmare. Still seeing a 45% defect rate and a lot of operators I’ve talked to are saying the same.