I recently picked up a cheap beat up European built magnetic stirring mantle. has anyone replaced the fiberglass heating inner sleeve on their units with the chinese ones? like in the link below… Also, how hard would it be to wire in a PID to control the heating element? i imagine it wouldnt be too hard…

i think an Inkbird PID with 106VH with a 2m K Sensor and a 25A relay could be easily wired in? just bypass the rheostat there now and wire the heating inner sleeve directly to the PID…

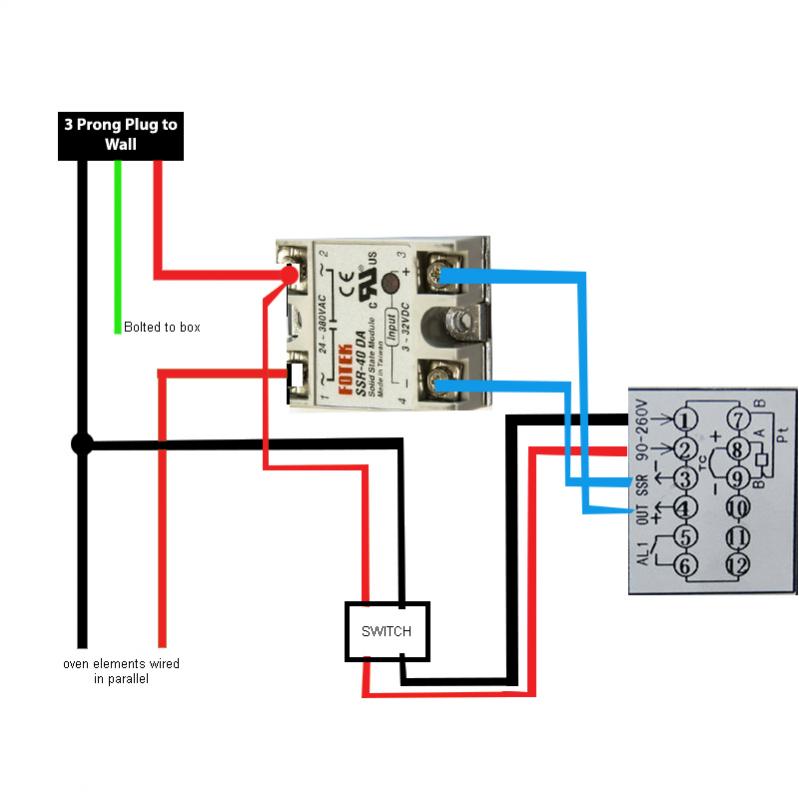

The pid is pretty streight forward, it will have a diagram on the back how it wants to be wired.

Basically it takes two leads from your thermocouple, and mains power to the pid. Then the pid is connected to a relay, it’s kind of like a switch in it’s wireing. One leg of your heater circuit will go through the relay as a switch.

my reading of the mantle (4.35A) suggests you could get away with a 5A relay style controller rather than having to find room to mount the PID and the SSR (and it’s heat sink)

you’ll notice it’s rated at 3A 250V, and 5A at 120V. picked this one because it actually has that rating on it. most of them will say 3A at 250V… and leave you to do the math at 120V

Oh sweet. Even better!

Do you guys know how well that Chinese fiberglass sock heater will work in replacement of the OEM one?

the only way we could really know, would be to have performed the exact same exchange…so no, nobody here knows…but a 2l round bottomed flask should be a fairly standard shape, so there is a decent possibility it will fit imo.

4.35a wouldn’t leave much leeway on a 5a relay. I wonder if it will work. I have a 12" exhaust fan that is supposed to 4 amps but still manages to pop a 5 amp fuse constantly.

yeah. I looked for one with a 10A relay. I know I’ve seen them before. not my project, so I only gave it 2 min.

it is critical to heat sink the SSR. they can get quite HOT.

edit: (mind you, I don’t think I’ve tried pulling only 5A through a 25A SSR ![]() )

)

A mechanical relay control will not like being cycled by a PID algorithm, to do that right you need one where you can adjust minimum “hold time” so that it isn’t chattering the relay constantly and wearing it out prematurely. And as @square_root_pharms pointed out, a relay rated for 5A doesn’t leave much room for error. Time is not kind to connections, bad connections mean more resistance and more resistance means more amp draw to do the same amount of work.

And IMO, most of the SSR’s on the Amazon/eBay and probably other markets are cheap knock-offs - including some falsely labelled as quality brands like Crydom and other US/Japanese semiconductors. It doesn’t cost much more to over spec the SSR and not have to worry about an imposter SSR crapping out when your distillation is nearly done.

would this be what i need? this appears to have a 10a built in relay but i cant tell if its an SSR or contacts.

Temperature Range -30 ~ 300 °C (-22 ~ 572 °F )

Blockquote3-It has built in relay , so it doesn’t need additional relay or SSR.

Agreed!

I realized when I spent a couple more min looking at it that I’ve used the even cheaper non-pid controllers when running the built-in relays.

solution? put the controller in an external box. or even buy one, already in an external box, so the fire marshal is more comfortable with it. maybe.

would this be what i need? this appears to have a 10a built in relay but i cant tell if its an SSR or contacts. I imagine i need an SSR to help with the constant On/off PID control versus a mechanical relay.

http://www.thermomart.com/index.php?route=product/product&product_id=227

Temperature Range -30 ~ 300 °C (-22 ~ 572 °F )

It has built in relay , so it doesn’t need additional relay or SSR.

I believe that is an example of the “even cheaper, non-PID controllers” I was referring to.

the NTC (negative temperature coefficient) probe it comes with is probably not ideal in this application. it’s more about the wire than the probe. the insulation looks insufficient for the projected temperatures inside the mantle.

unfortunately you can’t just substitute a k-type thermocouple.

I guess this will not be as easy as i thought and i definitely down want to dump 150 bucks for a fancy PID in a box lol.

Elliot Kremerman: You need a impedance matched pid. You will literally blow out the pid in twenty minutes. The entire relay and switch for the caps and power should be separate from pid. Thesemantles have a special step up voltage transofrmer than also steps it down to regulate a even power flow.

That sounds like elliot baloney to me!

Here’s a stir plate that has been specially buggered… it’s been in service for at least 4 years

Forgive the dust, everything’s tore up, we’re moving…

Ive got a hot plate i will want to do that with too! ha

It’s easy, dm me if you have any questions hooking it up.

i guess i need to find the currect one to buy first.

I was looking at this inkbird with a PT100 or K sensor and 25 amp SSR

That will work, a heating element really isn’t picky