Hello All,

First post. I am an extraction scientist and I have been running the VTA wiped film short path. We use CO2 resin produced from ExtraktLabs extractor that is waxy and green. I have been noticing that my THC distillate has a cloudy green appearance and I believe I see wax bands inside it. Any tips on how to improve the distillate? We are unable to winterize the material before running it through the SP due to licensing issues. Any help would be appreciated.

Thanks

If you cannot winterize you will have to employ selective solubility with your chosen solvent. This will be tricky with co2. Why can you not winterize? A table top hood isn’t an option? Or can you not use any solvents besides co2?

Dissolve in ph 13 water

Yields will be horrible thou

1 Like

Green hue is likely some terpene contamination. Waxy/hazy is going to be due to your regulations disallowing winterization

2 Likes

How does azulene behave on a wiper ?

Bleu and gold yellow make green

3 Likes

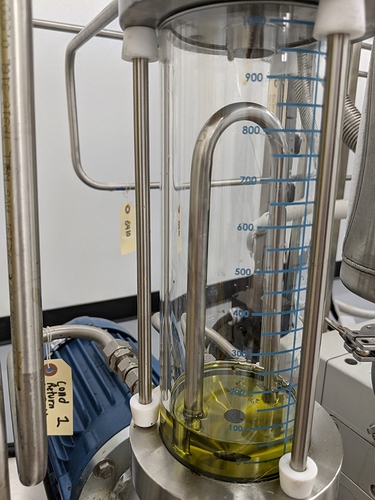

Here’s some terpenes on a first pass terpene strip on a WFE. I can get these to be more colorless by running a terpene strip at 130 deg C instead of 177 deg C, but my lights flask will be deep blue on the subsequent distillate run. I had pictures of the blue separation on another phone but that would require me to look for it.

2 Likes

You can avoid a bit of the fat by running a three cut sop on the wfd. First cut for terps, keep heavy fraction. Second cut run a tad high temp (don’t cook the beejeesus out of it tho so maybe 171-175 c or something like that) keep light fraction. Then take a sweet and low cut with temps 5-10-ish degrees lower, should leave many fats behind in the heavies

5 Likes

Oops this is thc distillation, right? You’ll want to cut the second and third passes a bit higher temp. My mistake

1 Like

The facility doesn’t have the proper licence to hold that much ethanol. On one of our extractors we’ve gotten the parameters down and no need to winterize. The EL extractor is horrible and gives us waxy resin.

Very nice. I am assuming you are using a chemtech? I am in the process of commissioning one but having a lot of problems. I think they sold us a lemon unit. Our terpenes are usually separated during the extraction process - but I do see some small amounts in the terpene catch after wiped film.

Yes, this is a 10. I know their units can be tempermental. Just as everyone else says on here, you need to fully prepare your starting material so that your vac isn’t fighting decarb or solvent. I’ve worked on cts units for going on three years now, if you need some pointers feel free to reach out. I posted a 6,10,30 sop on here somewhere too.

Thanks for the help! We have the KDT6 model. The first run I had Marlotherm leaking from the feed tank (Figured out they sent the wrong glass). 2nd attempt I had resin leaking from the feed pump, no distillate, but raffinate (residue) side had some resin. 3rd attempt my Julabo chiller kept giving me an “error 21” - tried to do a trial anyways and then my wiper motor gave me an error never seen (Wiper motor replaced under warranty and waiting for the julabo tech to come in). Havent touched it since.

If you got some tips on operation and parameters I would love to see them!

If err21 was on your chiller bath your condenser is dead or the cabinet wasn’t turned on to chill (there are two switches). You can tighten the three feed bolts to snug the packing against the shaft to stop leaks or just tighten the 4 main lugs to the feed plate. Sorry about all the issues, sounds like you’re working through them though. Are you running a turbo or diffusion pump, batched system or continuous discharge pumps?

Anyway, I’ll send my SOP when I have the chance today. It’s already posted on here so if you can’t wait you can try to find it.

Yeah I think the chiller is a lemon. This error was here since day 1. Everything was turned on and set up based on their manuals. I haven’t ran the turbo pump as of yet on the chemtech as I haven’t got through a proper run yet (but I did get a VAC of 0.00743 Torr on my first start up). I usually come in ready to start and within 15min or so I notice some issue and shut down the whole system.

I am currently running our VTA system but I cant get a deep enough vacuum. I think our vanes need to be replaced and possibly get a more robus vacuum. I also have a leak somewhere along the feed lines because vacuum will be as low as 0.2mbar then raise all the way to 0.7mbar near the end of the process. Its been getting worse and worse and I have taken apart the feed a few times with no avail. I am now running at 0.9mbar waiting for our reliability team to get parts in to rebuild the vanes.

Would using a hydrocarbon to winterize be an option?

Run into the same issues with licencing. I noticed that it only happens after running a specific strain. Going to see if we can ship that resin out to another facility for winterization.

I know it’s an old thread, but I figured this is relevant, and I’m officially stuck. So we bought crude from a vendor that did us the “favor” of running a terp cut on it beforehand, I believe they used a 6" Pope. I have no real experience running anything other than a VTA (VKL70/glass and a VKS/SS) I’m currently running a glass VKL70.

As soon as we got test results of our own on the crude, I loaded 500mL, ran Root Sci terp strip parameters, just to be sure, and no terps. Cool. So I do a run on 3000mL using RS distillation parameters, which usually net me anywhere from 88-92% THC and 95%+ on total cannabinoids, with roughly a 65-75% yield. This time, my yield was 58%. A full day later, distillate is unstable. Has a bit of a head to it. I’m thinking terps. Even though I already attempted this.

So now I’m thinking waxes, improper winterization. I slowed my feed speed to 20Hz, raised my coil to 95 to try to reject any of those lights that may be present. Now my yield is up to about 78%. Clarity is a bit better. Color is still amber, but I’m over that. The stability is what’s bothering me. I’ve never ran into this before with THC distillation.

Any thoughts on parameter adjustments if it is waxes? I read the previous post about raising both the feed vessel temp and the evap chamber, anyone try this?

Thanks!