I would say if you intend to put a gas that can expand and create hundreds of PSI, definitely make sure you have a good quality PRV on the jacket and get it with at least 4mm thickness on the jacket. For vessels intended for this purpose we use 5mm for the tank and jacket, and do a double layered jacket, one for heat exchange with dimples for surface area, and a second jacket that is stuffed with insulation then welded shut under vacuum.

Not shipped, we are ordering about a pallet worth of stuff building a pretty decent sized system. They quoted 230 for jacketed 6x48 with 3mm stainless, 4mm $318 , 5mm $355, also for a 200lb solvent tank with double jackets all 5mm $1780. All welding in pictures looks really nice. Well see how it goes.

We always just buy our stuff from usa suppliers , but had a friend recommend we use one of his contacts in china, was looking at all the parts they sell, almost all the usa suppliers just rebrand the china stuff and charge triple the price. It’s almost sickening. I understand there’s costs of running a business and what not, and if you need a part asap you can get it fast. But if you can afford to wait it’s definitely worth it. I see a lot of the local welders hate on the china stuff but the steel they source comes from china, as long as you can find a shop in china to manufacture it correctly i don’t see the problem.

Yep, you’re spot on. We manufacture everything in China at the facility we own and import it here, that’s how we can beat everyone’s prices. And we pay our welders over five times the median Chinese income so they love us and pump out quality welds day in day out. Saying that stuff manufactured in China is garbage is actually pretty racist, IMO. The Chinese are human just like anyone else and in a capitalist world they produce what you pay them to produce. The reason people have a bad idea about Chinese craftsmanship is because American companies ask Chinese companies to make the product as cheaply as possible so that they can make the most profit, then they blame China when people complain about the quality. Capitalism at its finest.

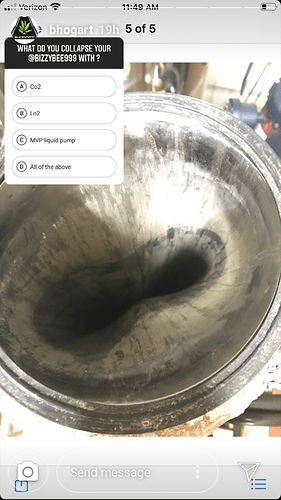

Ive seen a few of bizzy columns implode themselves

Are they going too cold with nothing inside them or what’s going on here

I think not many people had the full understanding of the way he chilled everything and the 10# prv’s for the columns seemed to fail when people cooled to quick from what i saw. It looked exactly like that but a quad rack.

That is SCARY.

Did you ever end up ordering these?

Pretty scary stuff. I would just hit up Exergy out of New England. USA made stainless 316 steel, and they are rated.

Buy some cryo PRV from NBoler. And swagelok needle valves. Running from the line of the LC02 / LN2 tank, manifold it like this (line goes to needle valve, to PRV and pressure gauge, to tank. Throttle the needle valve to what is needed for cooling.

Tanks do worry, you never know… the coils are much better for me…

If I were doing pure propane or a high mix, I would go LN2 for injection to get solvent hella cold. And like @Graywolf has said in past, LC02 on the recovery coils. Otherwise, just straight LC02 on my butane set up and have a HUGE outside tank because you’re gonna run through that sh*t. Works like a dream.

My own experience having units built in China, is that having a representative in China who knows their industry is key to uniform quality.

Not only knowing which Chinese companies have the best quality control, but to establish the quality standards in China, vis a vis stateside without a Chinese rep.

IE: Shooting blind without one, the prototypes were pristine. The quality control of a 20 assembly order, with an assembly containing about about two dozen parts, was mostly good, with the following exceptions.

The gasket groove in one of the fittings contained broken mold scabbing from the investment casting process and was not cleaned up during machining nor caught by the final inspection process.

There were also four “feeler” columns where they had been grafted in the middle and finished poorly. It felt like they were feeling me out on quality standards and agreed to replace all the rejects in my next order, but if there is no next order you are stuck.

I had serious issues with the 10" and 12" gaskets fit and finish. Enough so that I started buying gaskets made stateside.

I do note that the Chinese gaskets supplied by companies like Glacier Tank fit fine, have a smooth finish and don’t smell like cinnamon, so it is again a function of having agents that know which companies in China to order from.

There was also an issue with getting ASME Section VIII certification for the pressure vessels, so I had those made in the US in an ASME certified facility, with ASME certified welders.

WolfWurx systems were a combination of parts from all over the world, machined, welded, and assembled in the US of A, with union scale or better paid to the craftsmen.

I used US parts as much as practical, just like I drive a US made Jeep and Ford electric to help stimulate our economy but use an LG TV made in China, S Korea, Mexico, Poland, Indonesia, Russia, and India.

without calling anyone out i can say that using liquid co2 in CLS process is something best left to those who paved the way.

buy a BZB, if funds arent there then think of what a total loss would look like with improperly made gear.

google wont help you figure out what you need, you need an engineer. im sure @JonaaronbrayAzoth would be able to help out but not for free.

i have seen (purchased) columns from two other manufacturers (US and China) made “for liquid CO2” that failed before i ever got a hydrocarbon into the column, (ie in temp testing).

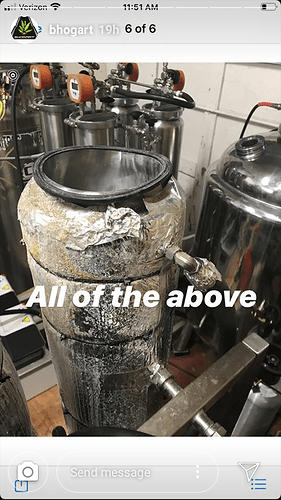

100% Love him or hate him Boris has proven throughout the years that his columns are safe to run Liquid Co2 through the jackets.

When I suggest a system with a cryo cooled column it’s always my first suggestion to go with a Bizzy column.

Bizzy steel is all 6mm thick to handle the Lco2 expanding into dry ice inside the jacket.

They say it’s cooled with Lco2 but it promptly just turns to dry ice in the system… the bottom port on the jacket is just left open.

6.O.D material columns typically use 1.09W or 1.134 Wall thickness.

I believe it’s 6mm on the solvent columns with 2” jackets and 5mm on the material with 1” jackets for whatever reason

Would love to get prices on some parts. You guys got a website or anything?