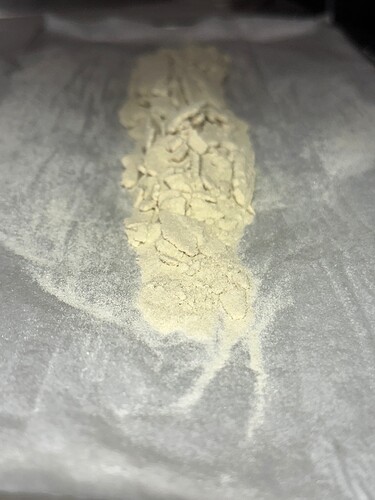

Why don’t you try mechanical separation on the THCa?

I work both sides,

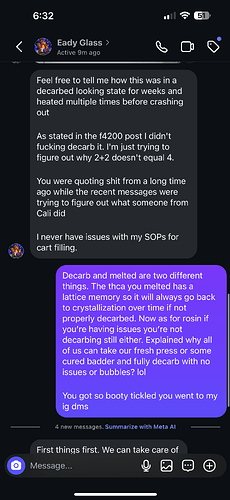

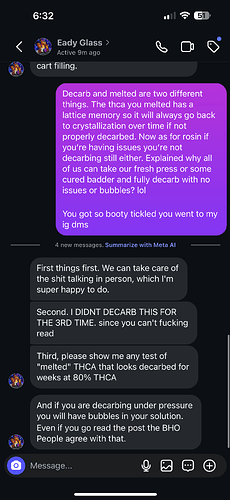

Hydrocarbons & solventless. I can tell you this, I can garuntee to run volume at quality and will do this all day. You came here whinning like a little spoon fed There We Are Then, and now have gone into my dms sayin you want to handle the shit talking in person cause I said you got booty tickled. I feel like you’re barking up a tree you feel is an easy climb. You having a good time yet? Do you feel big and Mikey? Do you drink monster by the case and act like you’re not scared to catch a case? Cause all this shit because for

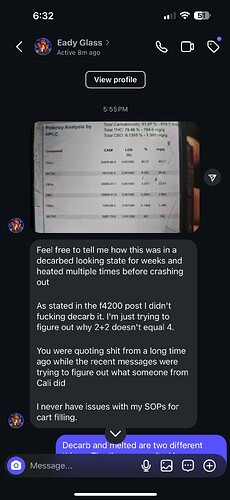

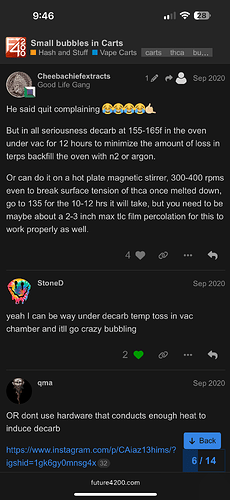

People have been telling you that what you were playing with was not indeed fully decarbed. That your flow path was not warm enough. Or to warm and caused further decarb to happen to said improper decarbed oil. Which you then whined about and likely did not fix the issue of.

Yes you may still have bubbles in your decarbed oleo resin, not your “solution” a solution entails that you have suspended something within your oil or your oil within something being a carrier / solvent.

Also for those interested here’s his ig and dms he sent on over and my singular response as I don’t entertain that shit for long.

Also your ig story is literally you crying to your followers which unfortunately I seem to be one likely due to the ts industries setups. I said nothing of the sort that the bubbles formed aren’t removed if not present but you do not have a full decarb one bubbles “seem to stop”. I garuntee you pull a vac they’ll show.

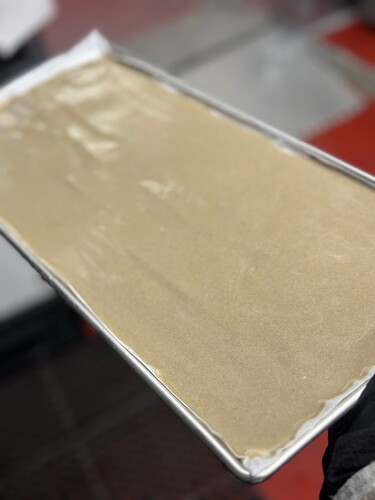

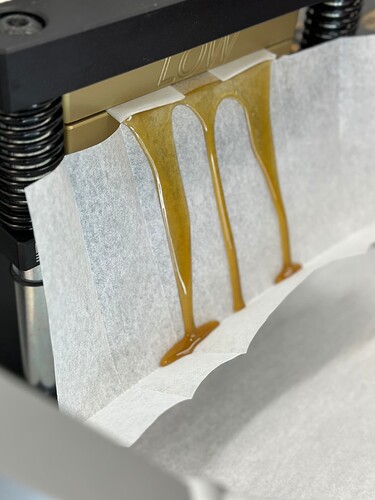

Secondly when decarbing live rosin for carts under pressure you will still have a slight amount of co2 present unless breaking surface tension in a thin layer to allow for almost all of your co2 to be removed which it won’t be unless under higher temps and forcing degradation of volatiles or under vac and reintroducing volatiles. Which you were also explained that as well.

Go ahead comprehend some hash tek for free since all you wanna do is talk shit bud.

You still answered 0 of the things that dont make sense.

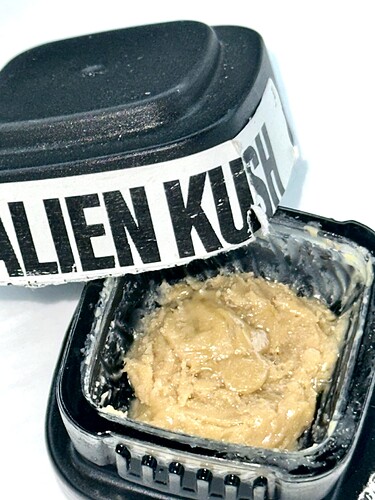

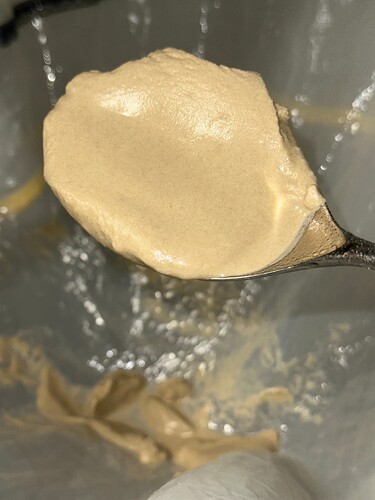

Also your rosin looks very midsy.

There is 0 debate about it not being fully decarbed. This is stated multiple times on my story which you are choosing to leave out.

You have answered nothing.

My original post which again you definitely didnt read or have 0 reading comprehension of was how to cheaply remediate out bubbles in a solution for rosin guys to have something to search and be able to do with what they have or for 50 bucks.

Then i had a bunch of BHO people tell me im wrong and i need to pull vac.

Yea, i literally have a BHO oven next to my bedroom, i used to do BHO stuff too and know you can easily remove bubbles that way.

That isnt cheap.

That isnt the best way to maintain terps even if it is the easiest way to do large batches at once.

There is no debate of people telling me i didnt decarb things long enough.

I never had a problem with them the guy who literally runs this forum literally sends me consulting gigs. I dont now, nor have i ever had an issue with my carts crashing back out.

I didnt decarb this as i stated a million times. Someone else did and what happened after and the testing that goes along with it doesnt make sense.

It crashed back out, as state on my story, of course it wasnt fully decarbed if that happened.

This is just a situation im aware of and worked on for a single part in the middle. I am not part of the company, just trying to make sense of things that dont make sense

You might lose like 1-3% by weight of a solvent HTE fraction that gets pulled down <1000 microns 30-40 times, and a lot of that is solvent weight. Add a cold trap and you can recapture the terps

You could probably get a cheap stock pot style vac chamber for that budget, anyone making hash probably already has a freeze dryer and vacuum pump, maybe even a cold trap?

@qma has a low temp syringe filler that might be worth looking into to avoid decarb in situ, way more than $50 though

I mean, yes, you can do all that, and testing may show a comparable level of terps.

I just find the best way of getting the best flavor is to use the highest grade starting material possible and manipulate it the least amount to achieve your end product.

Personally if im doing any separation and recombining id cold cure, fuge it, decarb the solids and combine vs cold trap complete solution and add back in but both are viable things to do IMO.

I feel like the taste gets a little more altered, not necessarily taken away with the cold trapping and adding

It’s so cute to watch you have a melt down since that’s all that happened with that thca and you can’t grasp it.

I also like the idea of pressurizing a container w nitrogen to decarb at low temps and know a company in Maine playing with that.

Like i said, this was originally just meant for a low tech cheap thing for the rosin guys who went to fill carts and had issues but i like all the extra playing around too

You keep not saying anything. Your rosin looks like trash.

I’ve never made a cart ![]() #bigfuckingairball

#bigfuckingairball

I’ve ran more disty Bho and hash than you can dream of. Try running 40k lbs of fresh frozen in under a week to hash. If I need to flex I can. I don’t need to call out a “person who runs this site” saying

I highly doubt sidco sends shit to you. You’re confused with future. And I can’t comprehend huh?

You “engineered” a cold ice wall for collections. Something so simple to achieve for much less money than you charge for your units. You’re a chad green taxing your own kind and don’t understand the science behind what you’re doing.

My unit sold for 6k at their highest cost, most were sold for 4k. 95 gallons full 304 passivated

The closest competitor was whistler tech which was similar to mine + a rotary vibratory sift which is about the same cost of manufacturing as my unit. 80 gallons

Theirs sold for 150k.

Then there is the nest, no ice filtration, 85 gallons 12.5k. Single stack, double stack like mine was 16k.

So i was 4x cheaper than the cheapest option on the market.

Proving again how dumb you are.

And i run big batches for companies too, not a flex.

Btw, you also didnt mention that my ig was only your comment and you were mentioned once or twice in reference to “Melting THCA” but then not mentioned again in the follow 8-10 as this is about finding out why the tests and stability of the solution dont match along with the % of cannabinoids in the tests not resembling rosin.

Im trying to get more information.

You are posting pictures of mid looking rosin and adding literally nothing to the conversation that explains any of the things that dont makes sense collectively.

My ig stories sparked a bunch of good conversation with people who had ideas other than “bad decarb” which is literally a nothing reply.

And the reason my unit was taken off the market was due to the manufacturer trying to charge me triple cause he found out how cheap the rep did it for originally and that it was for canna.

My only options were to actually start charging a green tax, have it made in china, or take it off the market until i can setup my own manufacturing facilities which is what i chose.

I tell you what, call around and get quotes for full passivation on a 5’ x 2’ × 3’ vessel with attachments, when you realize most companies want to charge you 1.5k for that alone, then price out a US made 95 gallon vessel with recessed drains and solid steel rings and get back to me on pricing for that cause most manufacturers themselves want 6-8k. Most people will have a hard time making one for under 8k total but i sold them at 4.

If you can’t put the fucking equation that a improper decarb meaning they melted the thca, making it appear to be in a liquid state it then had the chance to begin slowly making a crystal lattice form once again. There was likely a good preservation which that is the only thing I will give you a kudos on. Other than that you seem like you can do some great things, but ultimately have the shittiest attitude and a poor comprehension of science.

The ironic thing is the decarboxylation and back filling tek you spoke of originated from conversations on this forum and with mentions of it from myself.

A lot of the tek you see open sourced comes from a lot of us that you have apparently not listened to for years now.

So with that said. Have a great night I got chicken to go process.

I had to look at how long ago was one of the recent mentions, damn and been preaching it much prior to then as well.

As stated, on my story a ton of times, and in here.

I know it was a partial decarb

I understand a crystal lattice being formed.

Its the basics of making jam which I literally have a 60 minute paid talk at mothership glass on from a couple years ago. Ive been doing this shit.

Remember you were following me, not the other way around.

People who were actually helpful relayed the testing they had on batches that slowly crashed

No one had a test higher than 23% of rosin being in a distillate looking state for more than 72 hrs without crashing but eventually crashing.

And in none of those cases was the solution heated multiple times post decarb before crashing like this one was.

You referring to a partial decarb as melting is not the mind blowing thing you think it is. Its saying something thats already obvious which is that the original solution wasnt fully decarbed.

For the millionth time. Thats not the confusing part. Thats the obvious part.

The 3 weeks and multple heats, while staying stable is confusing.

The high testing % looks more like a BHO or filtered extract than rosin, that is confusing because its not mine and the person whos jars these are, says it is.

The 80% THCA still in the solution while being in a semi liquid state with 0 visible lattice or opaque parts forming for weeks while every other person who was able to provide testing on something simialr had between 8-23% THCA doesnt make sense..

Personally, i feel maybe the testing was wrong and it was just right on the edge of being able to crash, or lattice form if you need words to match exactly and just took a long time. As that is the only plausible situations backed by any science i can find that makes sense.

If you can add something to those points, great, if you are going to state things so obvious they dont even need stated and act like they are profound, IDK to tell you other than look up the valley of ignorance and how it may relate

Do you have the beam reagent on hand? Someone might have dumped a bunch of CBD in it

Unlikely with a test done, but labs make mistakes

This is actually what i thought happened originally as they do have some CBD at the facility. I think just isolate not disty but thought possibility of fuckery with that.

Since IMO the testing doesnt make sense, i wouldnt rule it out completely.

The other jar that crashes was 5% CBG which i know has some dif properties than THCA so I wasnt sure if that could have anything to do with but i had a homie with a lab in VT who hits 9% CBG on one of his and no issues like this, just trying to rule out anything since its weird.