So aside from prepping the material (freezing solid before entering the machine itself) what can one do to optimize the freeze drying experience? Beefing up the vacuum pump being used? I want to get top level performance from my crappy Harvest Right and don’t have 5 figures to upgrade to a LC so I figure looking at smaller level optimizations like a better vac pump would possibly lend to faster FD times as lately to get my full 12hr dry and 8 hr freeze i’m still cresting 36 hrs on 4 fat trays at a 35f dry temp. Trying to shave it down for optimization’s sake - but then again, limits are limits at times. Before anyone asks I have the 1st level oil pump for a HR and i’m very diligent about having a hard set schedule about oil changes (every 3 runs, no excuses, brand new robinair oil as recommended by HR)

Thank y’all for your input.

Pic for reference of what type of pancake batter I will be freeze drying

7 Likes

Fuck it, slap an Edward’s 30 on that bitch

7 Likes

What’s the lowest condensor temp?

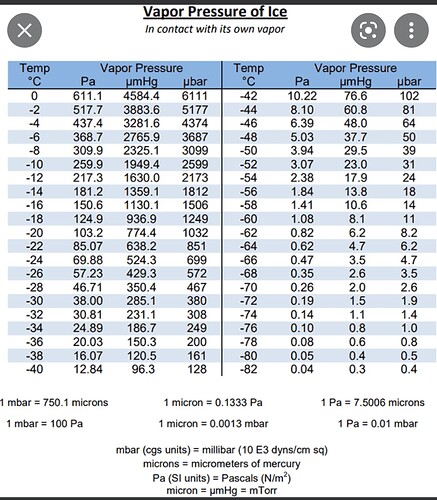

Too much vac can sublimate right off condensor.

4 Likes

Not sure, I run it typically at 30f the lowest, 35f on most runs. It’s a HR home version with a hacked firmware. Prior to forcibly making the firmware play nice it would only go to 75

1 Like

It looks like they have a max of -46c on the 3 L condensor. Does the harvest right have a vac controller? How low can you set it?

2 Likes

If it’s worth doing, it’s definitely worth over doing!

2 Likes

Some do but I have the super base model which is all manual I believe since my pump doesn’t have a small aux. voltage line to alert it when to turn off/on.

I’ll check out the hardware in a bit here once I coffee and adderall myself to cruising altitude.

3 Likes

I have a small pharmaceutical freeze dryer for sale never used if anyone is interested.

1 Like

Make a sales post @HydrocarbonaMarvin! How much u lookin to get for it?

1 Like

Im looking to get 2000 and buyer pays shipping Or local pickup in ok.