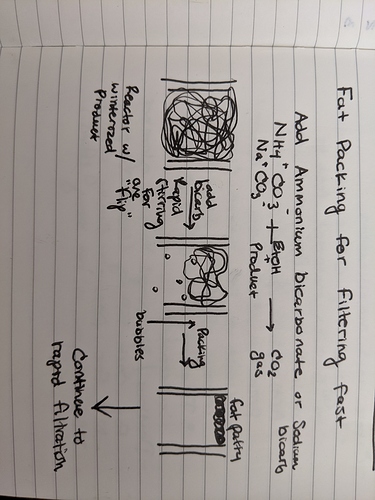

I’ve seen some using the term flocculation here and it got me curious how y’all have been using flocculation for processing needs. While in biotech we used to flocculate cell membranes and cell gunk from lysing kilogram+ quantities of E. Coli, though the process we used may not be processor friendly. The procedure is described as taking a calculated amount of Ammonium bicarbonate and dumping it into a reactor filled with bacteria, a couple detergents in % amounts, ethanol and water. The reactor is then turned on to the highest possible safe speed for a few seconds to move the bottom of the reactor to the top and dust the added NH4HCO3 throughout the solution.

At this point the solution reacts with the NH4HCO3 and releases ammonia, carbon dioxide and some carbonic acid. The bubbles, in a high enough concentration, are able to pack the fat patty into a floating disc which allows the bottom of the reactor to be bottom drained and speed filtered. The fat patty is then able to be either washed a second time or jammed into the filter of your choice. The filter we used was a two stage depth filter with a peristaltic pump upstream of the filter and downstream of the reactor, and being in biotech with all disposables, we would toss the jammed filter away. This was extremely helpful for getting a large portion of our process filtered as other processes needed to be performed day of and we were fully gowned in (annoying and time consuming to leave).

So - I see this being useful to some and useless to others. I don’t think anyone wants to smell a room full of ammonia. I’m able to stand it but I’ve dealt with much worse in my past so my judgment won’t align with everyone. I also think that ammonia could have some side reactions with the crude components, as well as raise the pH of the solution greatly. Water will be formed as a side product. But this isn’t the only salt that releases a gas and I believe there are other options for your gas generation salt of choice, this is just the process I know. The method doesn’t even need a salt if one of you fab guys have the ability to make a bubble generator through some sort of filter on the bottom of the reactor or you simply have the ability to spread an even, homogeneous blanket of bubbles throughout the entire solution. I don’t have any solutions there.

I don’t think many people are winterizing in reactors now a days, or at least doing filtration from a chilled reactor (less the Deutsche process people - I am jealous of you). So making this work would be for those who already have the infrastructure in place to “boost” your process speeds with this method. I have a crude hand drawn diagram for your viewing pleasure.

Is trying to cross apply this worth discussion? I had this idea years ago when I used to do the entire winter process in reactors so it may be obsolete at this point.