Hey just had a few questions about doing some live resin runs I plan on making some diamonds, applesauce and batter… since I’m starting with live frozen material should I load dry ice into my dewax column before I pack it with material in order to avoid creating moisture in my material column?? And should I crumble the frozen material up a bit as I load?? I feel like I have a pretty good understanding of post processing diamonds I wanna leave more butane and jar up, throw in freezer/on dry ice, burp the jars daily etc… batter I’ve read you pour out like a slab fully purge, then collect slab pull and fold it a bit then toss it in a Pyrex and whip over heat or whip and toss in oven and do that a few times…? Any insight is appreciated🙏 Thanks guys!

The badder you can collect straight from chamber & whip up to aerate the oil & then oven on low for extended time to get the best result. Diamonds you’re gonna wanna let the jar cold crash follow the strong sauce tek. The point is to let gas slowly release overtime to create faucets.

Think you should read more on “only the strong tech” for diamonds. I never burp jars daily when making diamonds

So I need to be chilling my delivery tank in order to do this or is that just a recommended step to take??

I’ve read this thread before I just get a little confused at step 3 when he says to turn on the recovery pump and I also don’t have a Buchner vessel… so do the most important steps begin with leaving the 1 lb of solvent behind doing the pour off and the the post processing steps??

Main thing is saturation levels. If your expected oil outcome is low, then leave less solvent. Will definitely take trial and error

Definitely chill the delivery tank for best result

If you’re just trying to make diamonds from a bho machine then I suggest you run a blend of isobutane or heptane for good diamonds but I have made them with bho & etho, just keep in mind you need a saturated (with oil) mother liquid to jar up, it will pressurize the lid to the band, this is a good thing, it means the reaction will begin to take place in cold temps. But all in all it’s a super saturated solution of oil & solvent that slowly gasses off in cold temps & crashes thc to the bottom & eventually forms “sauce “ which you then still have to clean of residuals of course. It’s all about seeing what works best for you but the initial idea of it is there. If you’re not comfortable with the band being pressurized, I suggest safety measures like a prv mod for vessels

Will I have more success the colder I keep my mother jar? Will the thc want to crash easier or faster if I can keep the jar -40 or colder??

The Thca will crash out of solution more completely the colder you get it. The saturation point of the solvent drops with the temperature.

As @that445guy nicely said it, the colder the better. Your goal is to achieve cold crash, which you can let diamonds form in warmer temps but it makes the “sugar” wax isnwhat then happens. Tiny nucleation really. I’ve pulled larger faucets from warm temps but nothing compared to clarity & quality of cold.

What’s the best way to make an iso+ dry ice or etho+ dry ice slurry last longer I’ve got my chest freezer which also doubles as my chiller for recovery tank and coil??

What temp and how long did you cool for?

Cold crash 1 day on dry ice/alcohol slurry. Then set at room temp for 2 hours before i put in oven at 85°f

Honestly it’s all a matter of how quickly the co2 is evaporating off. No matter what it’ll be hard to precisely time it out, but I mean the more insulated to better of course, but it will also need room to breathe the gas off ergo why a lot of people use coolers to make the slurry. But I always get it to a thick almost get like state as it gets super cold & can see frost forming on tank. Same with my columns but without slurry. I typically will let get cold 1-2.5 hours depending the quality of clarity & material I’m running.

Ok that makes sense I’m pretty sure I’m just overthinking it all anyways I’m just trying to ask the questions that I know will probably come up as I’m in the process of doing this all lol… do you have any insight to offer on making the LR batter I’m having trouble really finding out much…??

No worries we’re all here to level up together!

& as for badder tbh it’s really just whipping the concentrate before oven & finding the right consistency for you. Or if you’d like a little simpler but lengthy time wise sometimes just letting it chill on top of the oven will create a nucleation while the oven is warm & it will budder up.

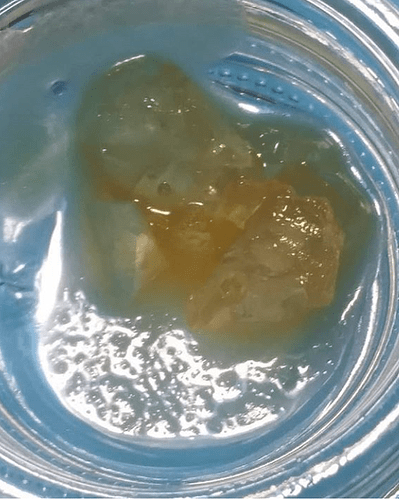

For an easy, low-effort sugar-in-a-jar tek, you can just collect your live resin directly into the jar, and leave it on a shelf with the lid on the top, but not tightened so a little gas can escape. The kind with a two piece lid consisting of a ring and a flat cap work great, because the cap rests gently on the top, while the ring holds it in place while loosened. After a couple days, enough solvent will escape that you can tighten it down without having to worry about breaking a jar or popping off a lid. If the lid is bending and deforming outward, you’re in danger of popping off the lid, or worse, cracking the jar. Longer, gentler curing, less agitation, slower evaporation rate, that is how you will get bigger grain sizes without having to do anything fancy. It just takes a while.