Anybody have a chiller -90C or lower? Have a couple questions I’d like to ask if you do.

Huber 915

$150k chiller… At one point, I thought our jury rigged 6-year-old Julabo was hot shit

Lauda has examples of this too

Yes, what’s your question

I have substantial experience building and servicing them although I don’t currently have one that goes that low on hand (ours maxes out around -50C). What do you need to know?

@TheGratefulPhil @FicklePickle @SidViscous @Dred_pirate

Question is I have my first-90C rated meter on hand. Factory has tested it to -90c with no issue. They want me to document a field test and drop the temp by 5 degrees every 30 min down to as low as I can go. And determine the failpoint.

I have a -90c chiller… but it’s a little old and doesn’t grt below-85.

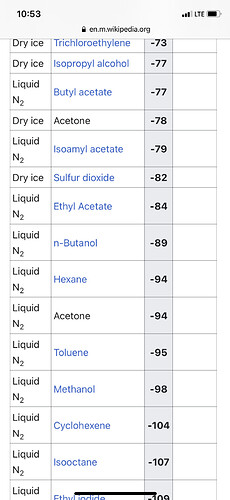

I designed a little closed loop with liquid n2, heat exchangers, and a circulation pump w/ a thermocouple to do the test. And the unit performed sub -100c. But it was determined the video documentation wasn’t sufficient to qualify it below -90c via FM/UL, etc. Because it was hard to be very consistent with the temp given I was sporadically injecting ln2.

So. Now I need to find a chiller that can fairly accurately hold these Temps and have access to it for 3 hours. (Could be at night)

It’s important to note the seals and meter housing are rated to -250c. The potential point of failure is not one that could result in a leak of some kind.

The fail point is the sensor getting too cold to effectively count the pulses. So we’d be looking to maintain a consistent flow rate more or less and watching to see if it stops being accurate.

If I can verify it’s functional at a lower temp… then I will most likely have the first -90c or below mechanic flow meter on the market. Which will help us quite a bit as the shift towards live extracts gains traction around the country and world.

Ps. Foe the sake of the experiment it doesn’t need to be a hydrocarbon flowing through thr meter. Could be some glycol blend or whatever that can handle the Temps with no potential risk of going boom.

Here ya go, B

These cooling baths can get to the temp you need, and a simply hydro-store pump will handle the super cold at least down to -50+

@Zack_illuminated is operating well below -90c now on his refrigeration unit. I wonder if he could implement your meter into his system

thanks joe. but I the problem is whatever liquid being chilled via the tube and shell doesn’t REALLY accurately hold temps… nor allow for reducing the temp in defined blocks.

For FM/UL certifications at those temps I need to have very clear visual evidence at defined temps for extended periods of times. So I cant just monitor the temp sensor and inject LN2 periodically to drop the temp back down when it goes outside the range we’re testing.

I already tried that approach. and they said it proved the point… but didn’t do so in a way that would hold up in a formal review

The cheapest/best way to do what you’re looking to do IMO is to use an electronic expansion valve (Sporlan Kelvin II) to control your N2 injection. For cheaper/more effort you could build a small PID on a simple PLC to control a needle valve but its a little tricky. Should be able to hold within 1C pretty easily with either method as long as you don’t run out of N2. It’s basically a cryo chiller without the compressor half or an upper stage

Or pay a more attentive monkey (@Bharris) to turn the valves…

After that -150c true cryogenic temp. Only 47 degrees away and I know exactly how to get there. ![]()

maybe just make an empty box and hide your valve turning monkey inside it for the purposes of the video lmao

Lolol ![]()