Hopefully a gas fired boiler of the same heat energy will work for this project and keep the OEM figures close as possible.

As far as oil, this will be my first.

Hopefully a gas fired boiler of the same heat energy will work for this project and keep the OEM figures close as possible.

As far as oil, this will be my first.

No, show us a picture of your falling film unit. Do you have it in you possession?

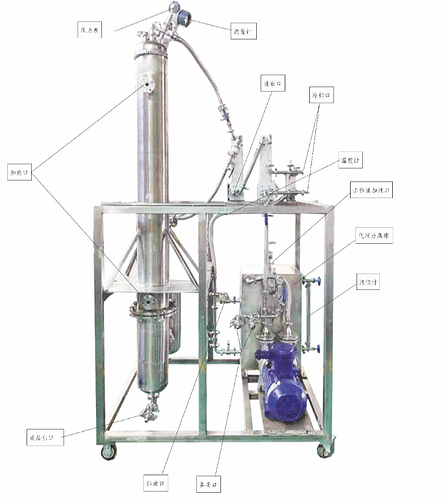

Looks exactly like the manual photo. i have photos of it actually set up in the room if needed.

What was the initial pic you posted?

The one the company had listed on Alibaba

What micron filter size do you recommend for particulates? 5 perhaps?

You should really filter down to 1 micron, or even sub (.5 micron). That seems to be what many people are getting down to on their filter trolleys.

Thanks for the input… do you recommend these sizes after extraction or after alcohol recovery from the ffe? just dont want particulates plugging instruments on the FFE

You should run them in series. Something like a bag filter to 20 micron, then a filter setup that runs 5 micron, 1 micron, and finally .5 micron. You should definitely do it while your product is still dissolved in etho, and before the FFE. There are people using regular water filter housings to run their product through. There’s also SS housings that will hold the filter cartridges, and many different types of filtering devices

Thank you for this valuable information. about a week away from making all this happen.

If you hit the search bar you’ll see all kinds of different ideas to use for filtering. That’s how I found about all of it. Lots and lots of reading…

What water heater do you suggest KOTK? Any links?

How many gph you trying to evaporate?

You need a high flow heater for a ffe

160ish gallons. What water heaters do you use?

The ones rated for commercial use typically allow higher temperatures and flow rates, fyi

Did you ever know how many litres per minute your creek water was putting in at what temp to run your original ffe?

Is well water good enough with a good heater?

This guy has a good steamer for sale in the classifieds. He’s also got spinner, but I don’t know if it’s big enough for what you’re looking for. Selling Equipment FFE 350L an hour solvent recovery! + other equipment 50% of!

So here we go, ready to start this up on monday. We opted on a 48kw electric heating oil system and we have our filter skid in place as well. so my machine is a knockoff of the deltta. with that in mind, would anyone know the starting parameters for starting this 250L FFE? Feed rate (kg/h), condensor temp and shell temp? Also it says everywhere that these things run constantly. Until i purchase another centrifuge, im looking to feed less into the FFE than what it can produce. i dont see a loop after it hits the recovery tank so how do you keep the machine going if there’s no feed at times? Would i just use the cavitation protection or just turn the vacuum pump off untill needed again? not sure turning it off due to keeping the tubes wetted.

How much tincture are you running?

My best guess is to manifold your vacuum pump in a way where you can close off the suction of your tincture and that way you can still have the vacuum pump do its thing on the FFE.