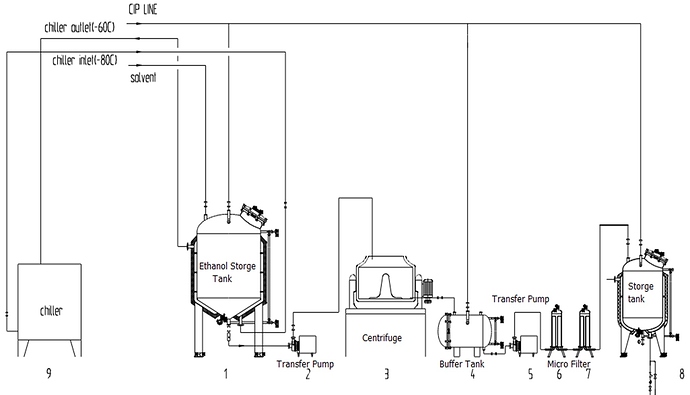

Solvent storage tank

- Design pressure: Atmospheric pressure

- Volume: 200L

- Jacket working pressure:0.25MPa

- Manufacturing standard: steel welded atmospheric pressure vessel.

- Material SS304."

Low-Temperature Coolant Circulation Pump

- Capacity of water storage: 200L

- No-load minimum: -80℃

- Flow (L/min): 40L/min

- Temperature adjustment: Room temperature-80

- Rated power (W): 550W"

Centrifuge(Explosion proof )

Dry material: 10kg per batch, 2-3 batches per hour"

"Buffer tank

1.Design pressure: Atmospheric pressure

2.In-tank medium: Extracted liquid

Micropore filter

- Flow: 3T/h

- Outer Diameter of Import and Export

- Pipe: 38.1mm

- Working pressure: 0.05~0.6MPa"

Storage tank

- Design pressure: Atmospheric pressure

2.Volume:150L

3.Jacket design pressure:0.15MPa - Manufacturing standard: steel welded atmospheric pressure vessel.

- Material SS304."

Single Effect Evaporator

Concentrate tank

Ethanol processing rate: 100L/H

Heater tube temperature: 117 ℃

Receiving tank volume: 200L

Cycle water consumption: 5T/h

Cooling tower

Cooling tower volume: 16.8m³/h

Product storageg tank

Volume: 200L

Design pressure: Atmospheric pressure

Jacket design pressure: 0.15MPa

Chiller (air cooling type)

Rated power (W): 9.5KW

No-load minimum: -5 ℃

Temperature adjustment: Room temperature -5 ℃

Flow (L/min) : 12 m³/h"