This method uses advanced techniques like moisture regulation, PVC pipe compression, and vacuum sealing for optimal Rosin yield and quality. I developed most of this method myself over the past years, so i wanted to share. I use only for flower rosin.

Materials Needed

- High-quality flower (60–65% humidity)

- Micron Rosin bags (90–120 micron)

- PVC pipe (slightly smaller diameter than Rosin bag)

- Rosin press (with adjustable temperature and pressure)

- Parchment paper (heat-resistant, non-stick)

- Vacuum sealer and heat-resistant vacuum bags

- Wooden dowel or tamper

- Steam pot or humidifier (optional, for rehydration)

Step 1: Prepare the Material

- Check Humidity:

- Ensure the flower is 60–65% RH. If too dry:

- Place the flower in a steam pot (on a rack) for 30–60 seconds.

- Let it rest for 1–2 minutes to evenly distribute moisture.

- Rest After Steaming:

- Allow flowers to cool slightly before processing.

Step 2: Pack Using PVC Pipe

- Set Up PVC Pipe:

- Choose a pipe slightly smaller in diameter than the Rosin bag (10–15 cm length).

- Load the Rosin Bag:

- Slide the micron Rosin bag over the pipe.

- Add flower material into the pipe, compressing gently with a tamper.

- Remove Bag from Pipe:

- Carefully slide the filled Rosin bag off the pipe, ensuring the material stays tightly packed.

- Wrap with Parchment Paper:

- Wrap the bag tightly in heat-resistant parchment paper to prevent sticking and protect the vacuum bag.

Step 3: Vacuum Seal(optional)

- Place in Vacuum Bag:

- Insert the parchment-wrapped Rosin bag into a heat-resistant vacuum bag.

- Vacuum and Seal:

- Remove as much air as possible to:

- Prevent Oxidation: Keeps terpenes and cannabinoids intact during pressing.

- Lower Required Temperature: The vacuum in the bag allowing lower press temperatures and preserving delicate compounds.

- Improve Yield: Moisture retention and lower boiling temps lead to more efficient Rosin flow.

Step 4: Press

- Set Up Press:

- Temperature: 100–104 °C (lower temperature due to vacuum-sealing benefits).

- Pressure: Gradually increase to 700–1000 PSI.

- Pressing Process:

- Place the vacuum-sealed, parchment-wrapped Rosin bag between press plates.

- Start with light pressure, then increase gradually.

- Press for 60–90 seconds, monitoring Rosin flow through the parchment.

Step 5: Harvest

- Cool and Open:

- Remove the vacuum-sealed bag, let it cool slightly, and open carefully.

- Collect Rosin:

- Use a silicone scraper to gather the Rosin from the parchment paper.

- Store:

- Place the Rosin in an airtight container to maintain freshness and quality.

Why This Method Works

- Prevents Oxidation: Vacuum sealing protects terpenes and cannabinoids from degradation, ensuring better quality.

- Lowers Temperature Needs: The vacuum environment allows pressing at lower temperatures, preserving flavor and maximizing yield.

- Moisture Retention: The process keeps optimal moisture levels for better Rosin flow.

- Even Compression: PVC pipe packing ensures consistent pressure distribution.

This improved process ensures premium Rosin quality while maximizing efficiency and yield. Perfect for extracting the best from your flower!

8 Likes

Any pics of the outputs? My personal SOP is:

- acquire water, ice, etc

- never make flower rosin again

12 Likes

Pre Pressed 3.5g pucks with a metal pipe back in the day

1 Like

If you’ve gotta press flower rosin and somehow have an aversion to extraction or just simply can’t this is a pretty good SOP. Thanks for sharing, bro!

6 Likes

I have seen a few cool cbd flower rosin product lines too. And that one strange TV show where they got a giant press for CBD

Thank you for asking, I try to make alittle documentary about it. Sorry for the bad pics im not professional.

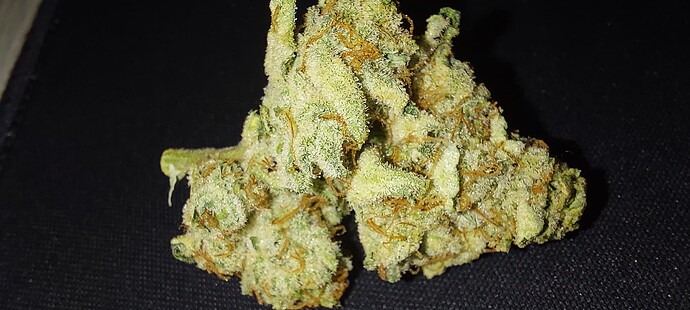

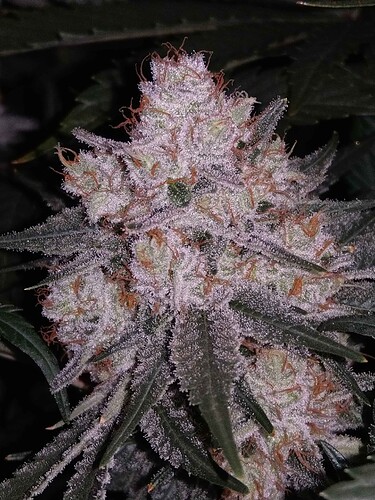

First grow a good flower(GG4 here in the pic):

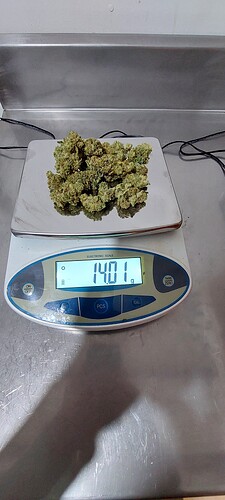

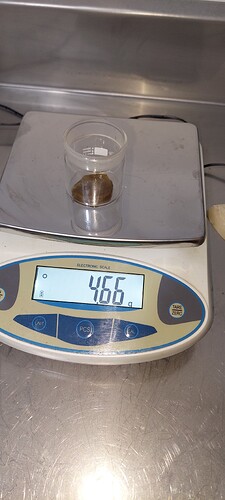

Weighting 14 g for the Rosinbag

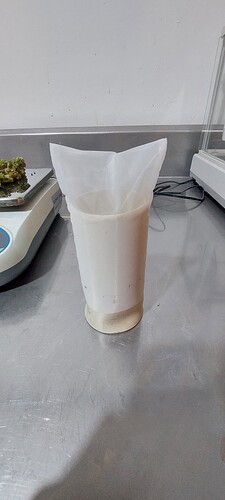

Put the Bag over the pipe, it helps alot for packing.

The finished packed and vacuumed bag. Ready for pressing.

Collecting the pressed Rosin.

4.66g of 14 g are 33% yield.

And here the end product, its nice but sure not like a ice water rosin. It will budder in some days.

8 Likes

Looks good for a home set up. But really looks like a lot of work for $10 worth of concentrate. Considering your grow time and cost and then your extract time and cost there is no way this is feasible in any legal environment in the world. Appreciate you sharing explaining the process though.

If you could produce that second pic of flower on a consistent basis you would not need to go further. Save the extract for trim done by someone else. Maybe a toll for a troll.

1 Like

Thank you for your feedback and perspective! I run this legally and on a small commercial scale. The process is absolutely worth it for me, as our mini-lab produces a variety of high-quality products. The consistent flower results are a key part of our offerings, and this process complements that by allowing us to make even more out of the harvest.

Beyond that, I genuinely enjoy experimenting and refining the craft—it’s part of what makes this work so rewarding. While scaling up would require a different approach, this setup works perfectly for our needs and goals. Thanks again for sharing your thoughts—I always appreciate a good discussion!

4 Likes

If it works for you and you keep your head above water that is great. I would smoke it. Keep at it and have fun. You are more motivated at that project then I could imagine to be.

You mention 100-110 C at 60-90 seconds 600-1000 lbs for 14g. How long of a warm up do you do? Have you tried lower? Say 80-90 C at 180-300 seconds 1500-2500 Lbs? How shatter like does it come out? Maybe the plastic bag drops the temps down a lot more?? In my experience this temp comes out with shatter like consistency.

If you’re looking for a shatter like consistency rosin isn’t what you’re looking for

Hey there, every strain responds differently to pressing, so you’ll need to adjust temperature and pressure accordingly. A good starting point is 100°C with 700 PSI—experiment from there. Always keep pressure as low as possible; pressing too much can introduce contaminants into the rosin. The same goes for temperature—if your strain works well with 90°C and 500 PSI while still delivering a good yield, stick with that.

For freeze-dried bubble hash, I use lower temperatures, around 60–80°C, and very low pressure. Remember, shatter is typically made with BHO and cold temperatures. What we’re talking about here is solventless flower rosin. In my experience, flower rosin tends to budder up after a few days and doesn’t maintain a shatter-like consistency.

Yeah it never stays shatter/sugary. It just comes off the press like that when I press at anything higher than 90°C. I was surprised by how high your temps are. You’re even saying they’re low. To me 90°C is high. I tend to stay around 70-85C for Flower Rosin.

1 Like

![]()