Are you doing the 120C oil bath swell?

No, I haven’t tried that hot yet but you should definitely preheat your material.

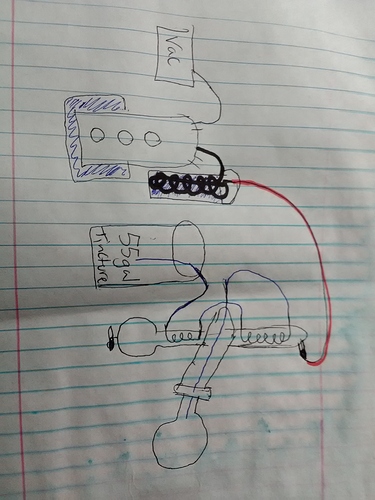

It would be cool if you could run your filtered alcohol/cannabinoid solution through your condensing coil as a preheating mechanism. Then from the top of your condenser (where you usually connect to vacuum manifold), connect to a secondary system such as a second roto or a stainless steel coil and collection pot. Pull a vac from the second system after the condenser.

Please excuse my sloppy drawing. The only problem here is that the connection from the top of the roto condenser is 3/8. Maybe we can get someone @spdking or @goldleaf_scientific or dare I say a Chinese mfg to make the connection at the top of the roto to be a 2 inch rather than the 3/8

Have you adjusted your flow rates on the chiller???

1.5 should be fine for a standard 20l. I have a feeling your flow rate is returning fluids too hot. What direction is the fluid going.

The fluid is at that temp, the inner material isn’t.

We have not adjusted the flow rates on the chiller, I will look into that. We are running the chiller return line through an ethanol filled bucket with a copper coil sitting in a -20 freezer and stoking it with dry ice, this has helped our condensation rate but the dry ice requirement seems potentially not worth it.

We are preheating our dipped/filtered ethanol through a waterbacth and bringing it to temp.

2" what? Hose barb? Let me know what you had in mind. I’m sure we can get one customized for you fairly quickly

I want to add this can and will probably void your chiller warranty. You might get ice build up. Anyways. You shouldn’t need any of that.

Start fluid routing from top of coil on roto and exit on bottom. Crank settings and safety alarms to 0. Crank chiller to -5c. This should work without any issues.

What you are doing is out of procedure most likely.

Cranks the psi up in the back corner untill fluid is flowing properly and returning mildly warmer than it comes in.

The reason we had to do this is because we can’t get the chiller to -5C when we are running full vacuum etc. We are sitting around 0 on average that’s why we had to add the additional cooling.

and what temp does that return the fluid to the chiller?

if it’s colder than the set point on the chiller, your (expensive?) chiller has now become a circulation pump…

I recommend put the booster on the outlet side of the chiller if you want your chiller to do any of the work.

have you read: Optimizing your RotoVap

Them hoses are do insulated its super convenient I’ll take pictures next time in in the lab

This is your issue on using so much dry ice. Flow path should be from the chiller to the dry ice bath to the condenser then back to the chiller. Let the chiller do most of the work and the dry ice will last longer and be more effective.

OP’s issue…

or would you prefer to disagree that we agree? ![]()

if you don’t suck so hard, you don’t have to get as cold to condense…

what is your goal post rotovap?

If you’re distilling, you might consider running oil in your bath and condensing at room temp.

I still think my drawing is the start of something badass. I’d throw probably a tube and shell in there to run off the chiller and keep the recovery tank on dry ice

i can hit -20 with super saline and dry ice and a 1200 gph fishtank pump… you should look into a glycol chiller

Bath mixtures of ethanol and ethylene glycol in dry ice produce sustainable constant temperatures over the range from -12 to -78 °C, which show a linear relationship between the bath temperature and the volume fraction of ethylene glycol .May 1, 2000

How much money are you looking to spend on an upgrade? I have multiple options depending on your budget

we have our PSI on chiller set to 40, factory setting is 80, where do you think we should be?

Is it possible our ethanol has degraded as we have used it many times, can this slow down recovery rate?

Also just to note, we are dipping at approximately 1Lb-2L using 10-15% the content, could this be affecting our recovery rate swell?