The concept of both power and temperature control is explained in the J-KEM 210 manual,

https://www.jkem.com/files/manuals2/210_Manual.pdf

Section 1.2

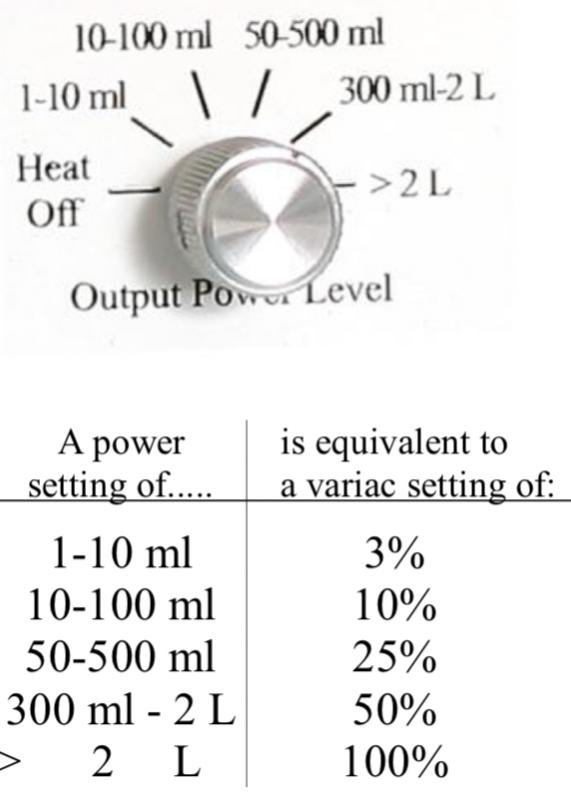

Set the power level switch to the volume of solution being heated (not the size of the flask being used). The power level switch can be thought of as a solid state variac. Volume ranges are printed above this switch as a guide to select the correct power level since it’s easier to guess the volume being heated than the appropriate “percent power” to apply to a heater. ‘Heat Off’ turns off the heater so the controller displays temperature only. All new users should read Section 3.6.

TIP: Because the power switch acts like a variac, if the reaction is heating too slowly or you need more power (e.g., heating to high temperatures), give the heater more power by turning the power level up one setting. If the reaction needs less power than normal (e.g., heating to low temperatures (<60o C) or the temperature overshoots the set point excessively, turn the power down one setting. DO NOT set the power switch on a setting too high initially to heat the reaction quickly and then lower it to the correct setting, this degrades heating performance.

3.6 Power Reduction Circuit. This circuit (12) is the interface to J-KEM’s patented power control computer which limits the maximum output power delivered by the controller. It determines whether the controller heats at a very low (1-10 mL), low (10 - 100 mL),

intermediate (50 - 500 mL), medium (300 mL - 2 L), or high (>2 L) power level.

The power reduction circuit acts as a solid state variac. This circuit has an additional setting: “Heat Off” which, when selected, turns heating off and allows the controller to act as a digital thermometer. The table to the right shows the maximum output power from the controller to the heater depending on the position of the power switch. The correct setting for this switch is the setting that supplies adequate power for the heater to heat to the set point in a reasonable period of time while at the same time not overpowering it. See Section 4.4 for a detailed explanation of how to correctly set up a reaction using your J-KEM controller.

(followed by a few pages of detailed examples ending with,)

The power reduction circuit limits the total amount of power delivered to the heater. In this sense it works like a variac and can be used like one. If the heater isn’t getting enough power, turn the power level up one notch, if it’s getting too much power, turn it down.

Section 4.1

2) Again referring to the range analogy, you’d obtain better control when heating small volumes if the range had more than two power settings; Off and High. J-KEM’s patented power reduction circuit (12) serves just this function. It allows the researcher to reduce the power of the controller depending on the amount of heat needed. This circuit can be thought of as determining whether the heating power is Very low (1-10 mL), Low (10-100 mL), Intermediate (50-500 mL), Medium (300 mL-2 L), or High (> 2 L). The proper power setting becomes instinctive after you’ve used your controller for awhile. For additional information see Section 3.6.

The Auberins controller does it all, with more precision (smooth 0-100% regulation) for way less moola.