$175,000

Falling Film Evaporator - FFE Series Ethanol Evaporation System

The innovative FFE Series falling film evaporator is ideal for botanical oil separation and ethanol alcohol recovery from your extracted biomass tincture. The system maintains a high evaporation rate, which significantly increases the throughput of crude oil production, eliminating the need for multiple large rotary evaporator systems.

Specifications

Evaporator&PumpCart 15’Lx7’Dx9’H

Dimensions

Evaporator 41”L x 32”W x 99”H

104cm L x 81cm W x 249cm H

Dimension

Pump cart 52”Lx32”W x74”H

132cm L x 81cm W x 188cm H

Weight

Evaporator Approx.400lbs

Weight

Cart Approx.600lbs

Included Ancillary Equipment

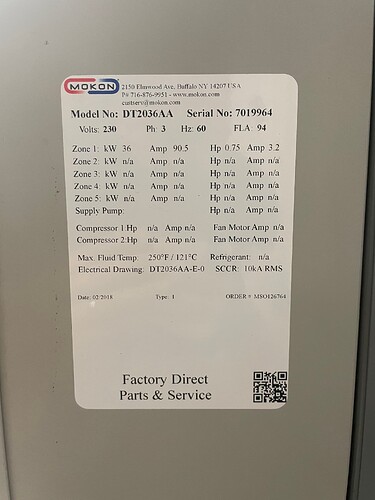

Recirculating Electric Heater

- Heating power:

- (Option 1)36 kW /97 amps@240V three-phase

- (Option 2)36 kW /48 amps@460V three-phase (Requires Professional Installation)

- Transfer Fluid Flow: 25GPM (25PSI)

- Max temp: 250°F (120°C)

- Transfer Fluid Line Connections: 1.5” FNPT

- Dimensions: 33”L x 17”W x 52”H

- Approx. 255 lbs

Recirculating Water Chiller

Pump Chiller

- 5.7kW /25amps @230V, single-phase

- Cooling Power: 1.5 ton

- Coolant Flow: 3.5 GPM

- *Ambient Temperature: -10°F - 35°F (Low or High)

- Dimensions: 30.5”L x 19”W x 26”H

- Weight: 340lbs

DOES NOT INCLUDE RECIRCULATING WATER CHILLER

Throughput

With its unique design, the FFE-Series Falling Film Evaporator greatly increases the throughput of botanical oil production boasting an impressive 60 gallons per hour of alcohol recovery.

Residence

Less contact with high heat alongside speed of processing makes the FFE-Series an essential part of the processing line. Short residence time is ideal for heat sensitive botanical compounds and decreases the risk of burning oil.

Falling Film Evaporation with the FFE

The Falling Film Evaporator (FFE) has its own take on the technology, incorporating improved features that keep the operator in mind. As a large portion of the tincture processed using a falling film evaporator is coming from a cold ethanol extraction, the design takes advantage of the cooling power that is already a sunken cost in the form of the electricity used to generate it. This power is harnessed as the vaporous ethanol is condensed on a heat exchanger channel that shares a surface with the inlet through which cold tincture flows as it is prepped for evaporation. This small touch of engineering relieves stress from the Falling Film’s chiller that is working independently to cool that heat exchanger.

Among the other benefits the FFE unit is the ability to run a clean-in-place procedure. This means that the inlet and outlet of the evaporator can be linked to a clean ethanol supply and allowed to recirculate virgin tincture to concentrate the waste and clean the inner surfaces of the evaporator. Maintenance of this level ensures the longevity of this premium platform and makes for consistent end-product.

In keeping with the scaling nature of a biomass lab, the base 45 gallon per hour model of the falling film can be easily upgraded to the 60 gph version by simply upgrading the chiller to a larger size.

Lastly, with regard to the high viscosity of flower oil, and the tendency to lose yield along the surfaces of the vessels used to transfer the products. As the crude oil is concentrated by the falling film, a dilution of 5%-12% ethanol is left in the mixture to give the concentrate a workable texture. This makes it very easy to transfer the concentrate to a decarboxylation vessel where any moisture and residual solvent will be evaporated off ahead of the removal of the acidic groups found on the cannabinoids.

All in all, with few movable parts to break, and the ability to make it a close loop machine, the Falling Film Evaporator should be a welcome upgrade to any lab wanting to move closer to full automation and avoid a cumbersome maintenance schedule.

Uploading: IMG_0952.jpg…

Uploading: IMG_0953.jpg…