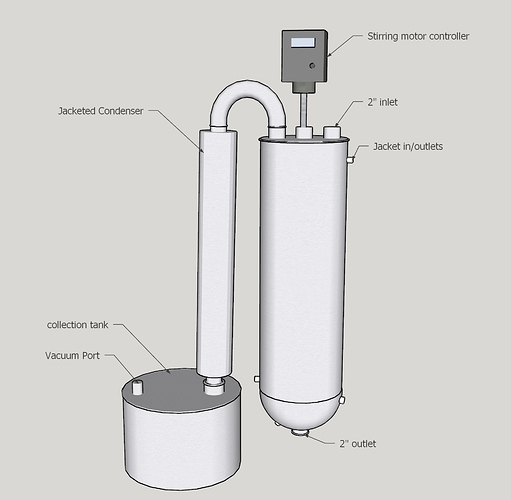

Hey. I’ve designed a post processing set up, I guess its pretty much a jacketed reactor built from tri-clamp parts. I wanted to see what you all thought of it before I get it built, any possible problems or general critique.

This is just a quick drawing. Basically its an 8" x 24" jacketed column with a round bottom to 2" reducer. A 4"dia x 24" jacketed condenser to a collection tank with a vacuum take off. There will also be other ports for gauges etc.

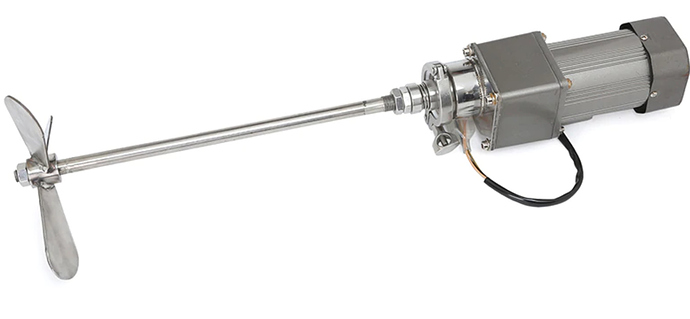

I’m planning on using this tri clamp stirrer/mixer component which will reach to the bottom:

It will come with a speed control etc.

I’m not using this for extraction (but I guess I could), this is just post processing. I start with crude which needs decarbing and then dissolving in etho which will all happen in this column. I will have a second similar jacketed column which will be chilled for winterizing and have a few filtering stages. The processed slurry will end back in the above column (but the round bottom reducer will be swapped for a jacketed ‘splatter platter’) to distill and collect the etho.

Basically it’s a two column jacketed system that has a hot tank for mixing and distilling and a second tank for filtering, polishing and winterising. I hope that makes sense!

This is a small scale thing for personal use mostly, but I want it to be good (and safe!) because I don’t know where it could take me in the future. A friend works for a steel manufacturing co that makes equipment for food grade water systems and breweries etc so I’m getting this done dirt cheap otherwise I probably wouldn’t bother. I already have all the other bits to run this.

What do you guys think? Any obvious problems that I’ve missed? Any concerns? I won’t take it personally ![]()

![]()

Cheers,

Kit