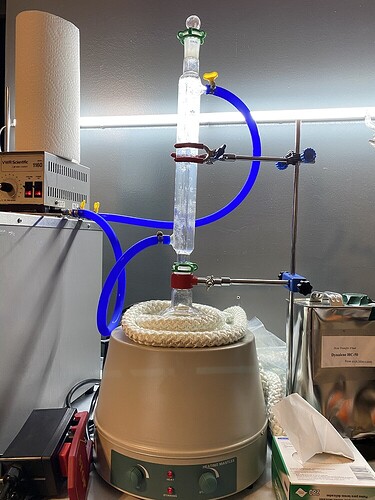

Woah; please tell me that you didnt run at reflux with a stopper in the condenser

Came here to say this although I assume he stoppered it after finishing the run.

Also…

Shake it like it owes you money. Words to live by. If it won’t separate, increase the difference in polarity (e.g. salting out or making sure there are no solvents miscible in both phases), reduce the temperature, and/or spin the mofo (centrifuge it up). Check out how different salts are more/less effective at salting out (epsom salt is a winner fyi).

Also, make sure it’s dry dry dry before DCVC, even .10% water in the solvent can make a big difference.

What, you mean exploding glassware isn’t an exciting part of your day?

I stoppered prior to emptying the column fluid, not that it helped with the smell.

That’s a great tip, I recall a discussion somewhere around here about different salts having different effects; I hadn’t looked into it any further but I appreciate you saving me a step!

Current plan is to load dissolved solution with DE (i don’t have 545 handy), pop it in the roto (it’s kinda silly to use a 5l roto for like, 300ml solution ![]() ) then load up a column; currently thinking (bottom up):

) then load up a column; currently thinking (bottom up):

Pure sand to create a stable layer above the part where it tapers.

DE (enough for 1 inch layer in 60mm column)

T5 10g

Silica 10g

B80 60g (assuming 20g oil with a 3x ratio)

I actually do not have heptane, apparently ordered n-Pentane from two different sources ![]() so I used hexane, I think I’ll continue with that (unless there’s any other advice) planning to use ethyl acetate or acetone at or around 10% intervals per @Beaker’s excellent posts on the topic.

so I used hexane, I think I’ll continue with that (unless there’s any other advice) planning to use ethyl acetate or acetone at or around 10% intervals per @Beaker’s excellent posts on the topic.

Alternatively, if I can figure a way to jacket the column to -10c or below, i could try the media I received from Luna tech; probably try this one next.

Question. How might I adequately determine everything is dry enough?

I’ve run at low reflux temps with no condenser- a little pressure isn’t the end of the world right?

A phase contactor

Is essentially, a column that allows for lots of interaction between two liquid phases, without any agitation or vibration or stirring, moving parts that lead to emulsions and problems separating phases.

They are very very very useful in water washing cannabinoids, especially when neutralizing acids with bases which lead to the formation of salts that tend to create strong emulsion layers.

There are a ton of different ways to build one-

but for the sake of Long story short-

stuff a triclamp column with stainless steel wool, dissolve your oil in heptane, enough to fill a little less than half of the packed column, pour the oil/heptane into the column, and then pour water/brine into the top, use a valve on the bottom to slowly bleed it at the same rate that you’re filling/pumping water through the top.

You’ll need much less water to neutralize and you’ll never make an emulsion, and if you use a pump, it’s even easier- recirculate the water a few times if you want or just keep running fresh liquid through.

Set it and forget it.

you dried the flask only to introduce 0.6g of water?

If you dry load the solution you probably won’t have an issue with water as long as you take reasonable efforts in the rotovap. I fucking hate scraping the powder out of the flask lol. If you liquid load, you can build a small layer of a suitable drying agent on top of the column.

You may want to try straight silica 60 if you want to actually collect fractions with your DCVC. Other media are not usually added to the process and it might cause some dramatic yield loss or smearing of fractions (you will need more solvent to elute from the b80 and that can push fractions through early in the silica).

If you are just polishing with a filter stack (i.e. buchner funnel CRC style) I wouldn’t bother with the dry load. Just bake some epsom salt out real well until it’s anydrous, grind it up in a coffee grinder and put it on top of your stack. It should grab any trace water as you pour the solution through. Remember to bake your powders out too

Very interesting!

Am I understanding the mechanism [vaguely] correctly? The lighter oil will be moved up the packed column interacting with the stainless steel wool and the brine solution; which effectively acts as a large surface area to make contact with. The heavier water would fall down in the column constantly displacing and moving the oil around, upward, improving the amount of contact it has?

What happens after this apparatus? Do you move the entire solution to a sep funnel?

That’s correct. I have not yet looked into converting it to anhydrous phosphoric acid in my home setting. I would further wager that my heat gun didn’t fully dry all the glassware either; I would further wage there was plenty of oxygen and water exposure during the reaction, being in open air with only an argon blanket.

All of this is understood, with the idea of not letting perfect be the enemy of good. I’m learning, gaining experience with processes and techniques. I’m not perfect, or very knowledgable and I know my reactions aren’t lab grade today. I’m okay with that

You’re absolutely right and I was high as hell pulling from the wrong procedure notes ![]() . That’s what I have down for trying ‘water clear’ on the output.

. That’s what I have down for trying ‘water clear’ on the output.

I’m thinking of loading a dry boiling flask with some epsom salt and letting that sit in the mantle for a while. (I’m very hesitant about cross contamination in my home environment and I don’t yet have an oven for the lab).

That’s a great tip that I did not have anywhere in my notes about using epsom salt and it makes sense in retrospect.

I may try wet loading first and see how it goes. I’m not sure yet. When I do get started on the DCVC column my plan is base layer sand/de, then some stupid expensive silica 60 (same one mentioned by Daniel in the DCVC video) and probably now a layer of baked epsom salt because why not?

Still planning on using hexane/heptane and acetone currently.

Don’t wipe a lone raindrop off your car before you drive it into a car wash though, instead just nuke the car wash

If you have any suggestions to try in a home setting, I’m all ears. One of the patents I came across essentially appeared to be dry loading the phosphoric acid

EXAMPLE I

A dehydrated phosphoric acid product according to one aspect of the invention was prepared by mixing 2.4 parts by weight of a 75% aqueous solution of phosphoric acid to 1 part by weight of air dry peanut hulls. The ingredients were mixed thoroughly and then dried for 3 hours in an electric, hot, still air oven at a temperature of between 240°-260° F. (115°-127° C). As the mix was heated and drying progressed, the color changed from a light brown to black. During the drying process the mix first became a wet slurry before beginning to dry. The mix was also stirred occasionally to facilitate drying. The final dried product was a black, finely-divided powder upon being removed from the drying oven. The black powder recovered has a phosphoric assay of 22.6% by weight and had a phosphoric acid equivalency of 95% of a 75% aqueous solution of phosphoric acid.

Being as I run the reaction in isopropyl alcohol, I can’t help but wonder if the polar nature of the solvent will pull out the phosphoric from something like celite 545, allowing for dry use of it.

It further seems drying would need to be done under vacuum preferably below 140c to avoid polymerization of the phosphoric acid if I’m not mistaken; according to another thread somewhere around here.

Appreciate your insights @roiplek

Ok so I might be recalling incorrectly but one of my advisors blew up a reaction once and an oil based phosphoric acid splashed on and burned his face making it really hard to get off. Idk if he prepared it or not and a quick Google search turned up nothing. The article about the explosion only mentions sodium azide which was the compound that detonated. Maybe a more well versed chemist can chime in but I think a water free oil based sulfuric or phosphoric acid exists as a product.

Dry acid suspended in mineral oil maybe??

If anyone wants to hear about the horror story of a lab I was trained in, even so I still have massive amounts of respect for all of my advisers: https://www.gainesville.com/article/20120112/SPORTS/604130664

Maybe thats the phosphoric pentoxide I’ve seen mentioned?

the polar nature of the solvent makes it mix very well with water most of all. so that’s a hard no, sadly

polymerization is inevitable and actually necessary.

Don’t use 85% phosphoric if you wanna go for d9

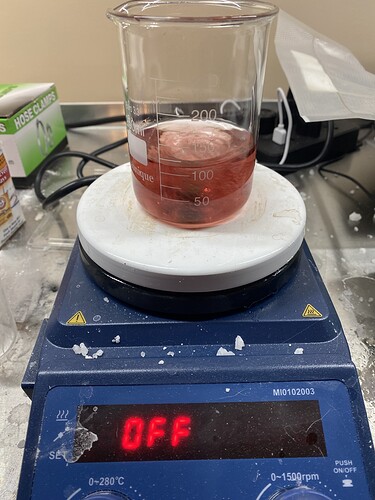

Just messing around with that first blob of snot; put it in the sep funnel with some hexane and iso; washed a few times then ran through a column of:

100g sand

250g DE

60g b80

30g silica 60

Ran the solution through the column under vacuum twice

It’s currently on the hot plate evaporating off the hexane (this R&D has been very wasteful whoops), it’s taken on a rose tint.

A few things I’ve learned from this little run today.

- It seems I am unable to use baking soda to get water above a ph of 8.1.

- Measuring the amount of media used is inconsistent; I’m using a shipping scale ±2g but the vibrations and what not being on the second story interferes with the accuracy of the scale. I would need to fix this; probably using vibration isolation pads like on my other scale.

- packing a column is clearly an acquired skill. I have a PTFE packing rod thats gets most of it down somewhat, banging on the column with a cork to level it out; my spatulas (flat edges) are not good for packing down the edges of a column.

- i need to find a more suitable thermometer, the probe doesn’t fit any of the fittings I have; or find a glass insert instead.

did you pour the silica in such a way to definitely avoid inhaling any particles?

Certainly not as well as I would have liked. I wore a full mask respirator and had the room fan evaluating air at all times while dealing with all of the powders.

Do you have some technique tips?

Wet loading also disrupted the layers more than I would have wanted

In the immortal words of @roiplek

This is probably it- have seen this plenty of times