Did you see what @BC9696 posted last week about the aluminum valve seals not sealing well and causing this exact issue?

He said he heard this from both ETS and Corken technical support.

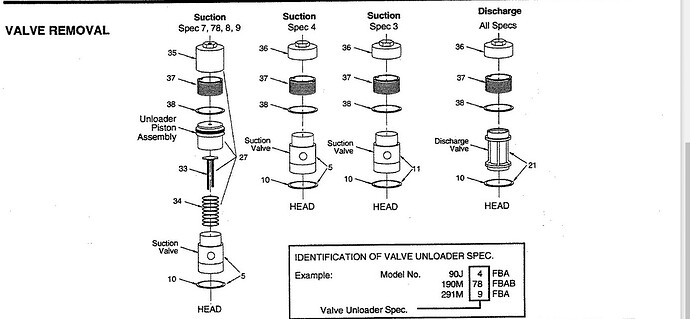

If you look under suction valve spec 3 below I believe he’s talking about gasket #10, which should be aluminum. If you either reused or didn’t really tighten down the valve body, this gasket could be very likely be your issue.